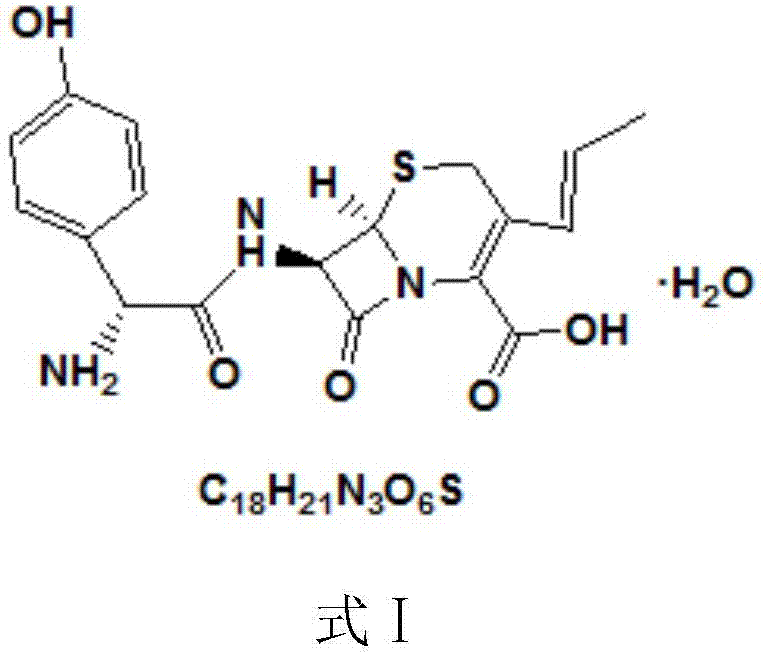

Method for synthesizing cefprozil by enzymic method

A technology for cefprozil and enzymatic synthesis, applied in the field of medicine, can solve the problems of long reaction period, low yield, and many impurities of cefprozil, and achieve the effects of reducing the use of solvent, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

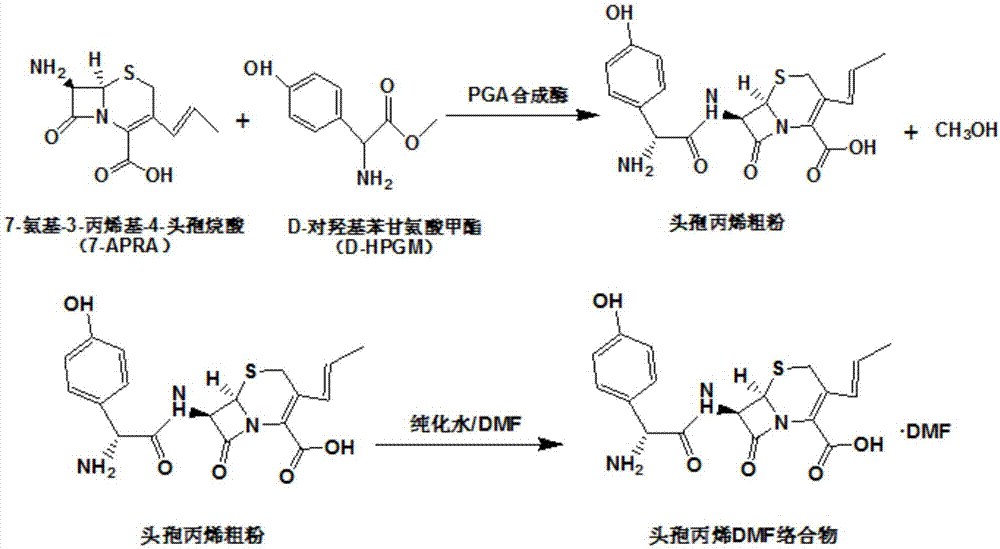

Method used

Image

Examples

Embodiment 1

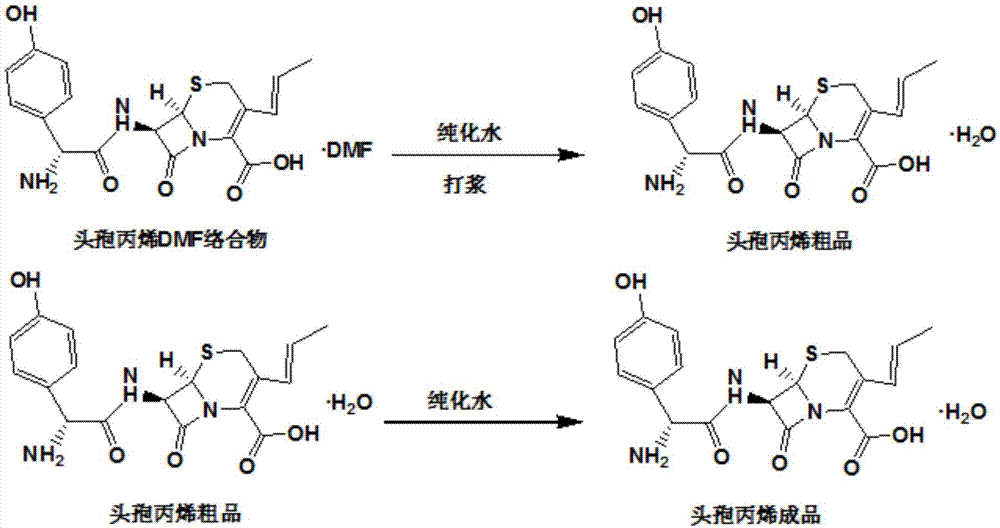

[0031] Add 40g (0.1665mol) of 7-APRA, 34g (0.1876mol) of side chains into 120g of purified water, add 28g of PGA synthase, keep the temperature at 5-10°C for 5 hours, and monitor by HPLC until 7-APRA≤3.0% After the reaction, use a 100-mesh sieve to separate the enzyme, coarse powder, and clear liquid. Add the coarse powder to the clear liquid and adjust the pH value to 1.0 with hydrochloric acid to dissolve the clear liquid. Then add 600g N, N-dimethylformamide and control the temperature. Adjust the pH value to 5.0-6.5 with ammonia water at 15-20°C to crystallize, stir for 30 minutes, cool down to 5-10°C to grow crystals for 30 minutes, filter, and then dry at 40-45°C to obtain 73.1g of cefprozil-DMF complex, yield 95.3%, purity ≥ 98.4%, light yellow.

[0032] Add 73.1g (0.1578mol) of cefprozil DMF complex to 150g of purified water, control the temperature at 10-20°C and stir for 30 minutes, then filter, add the filtered wet powder to 100g of purified water, control the tempe...

Embodiment 2

[0034] Add 40g (0.1665mol) of 7-APRA, 34g (0.1876mol) of side chains to 160g of purified water, add 28g of PGA synthetase, keep the temperature at 5-10°C for 5 hours, and monitor by HPLC until 7-APRA≤3.0% After the reaction, use a 100-mesh sieve to separate the enzyme, coarse powder, and clear liquid. Add the coarse powder to the clear liquid and adjust the pH value to about 1.0 with hydrochloric acid to dissolve the clear liquid, then add 600g N,N-dimethylformamide, Add 1g of activated carbon for injection to decolorize and filter, control the temperature at 15-20°C and use ammonia water to adjust the pH value to 5.0-6.5 to crystallize, stir for 30 minutes, cool down to 5-10°C to grow crystals for 30 minutes, filter, and then dry at 40-45°C to obtain 74.8g of cefprozil-DMF complex, yield 97.5%, purity ≥ 99.1%, pale yellow.

[0035] Add 74.8g (0.1615mol) of cefprozil DMF complex to 180g of purified water, control the temperature at 10-20°C and stir for 30 minutes, then filter,...

Embodiment 3

[0037]Add 43.8g (0.1665mol) of 7-APRA, 90.53g (0.4995mol) of side chains into 200g of purified water, add 28g of PGA synthetase, keep the temperature at 5-10°C for 5 hours, and monitor by HPLC until 7-APRA≤ 3.0%; after the reaction is over, use a 100-mesh screen to separate the enzyme, coarse powder, and clear liquid. Add the coarse powder to the clear liquid and adjust the pH value to about 1.0 with hydrochloric acid to dissolve the clear liquid, and then add 1000g N,N-dimethyl formazan For amides, add 2g of activated carbon for injection to decolorize and filter, then control the temperature at 15-20°C and use ammonia water to adjust the pH value to 5.0-6.5 to crystallize, stir for 30 minutes, cool down to 5-10°C to grow crystals for 30 minutes, filter, and then at 40-45°C Dried to obtain 76.5 g of cefprozil-DMF complex with a yield of 99.75%, a purity of ≥99.9%, and a light yellow color.

[0038] Add 76.5g (0.1652mol) of cefprozil DMF complex into 300g of purified water, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com