Desalting method of combination of microbiological fuel cell and capacitive deionization

A capacitive deionization and fuel cell technology, applied in the field of desalination, can solve the problems of high cost and low desalination efficiency of ion exchange membranes, and achieve the effects of reducing costs, enhancing current collection, and excellent use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

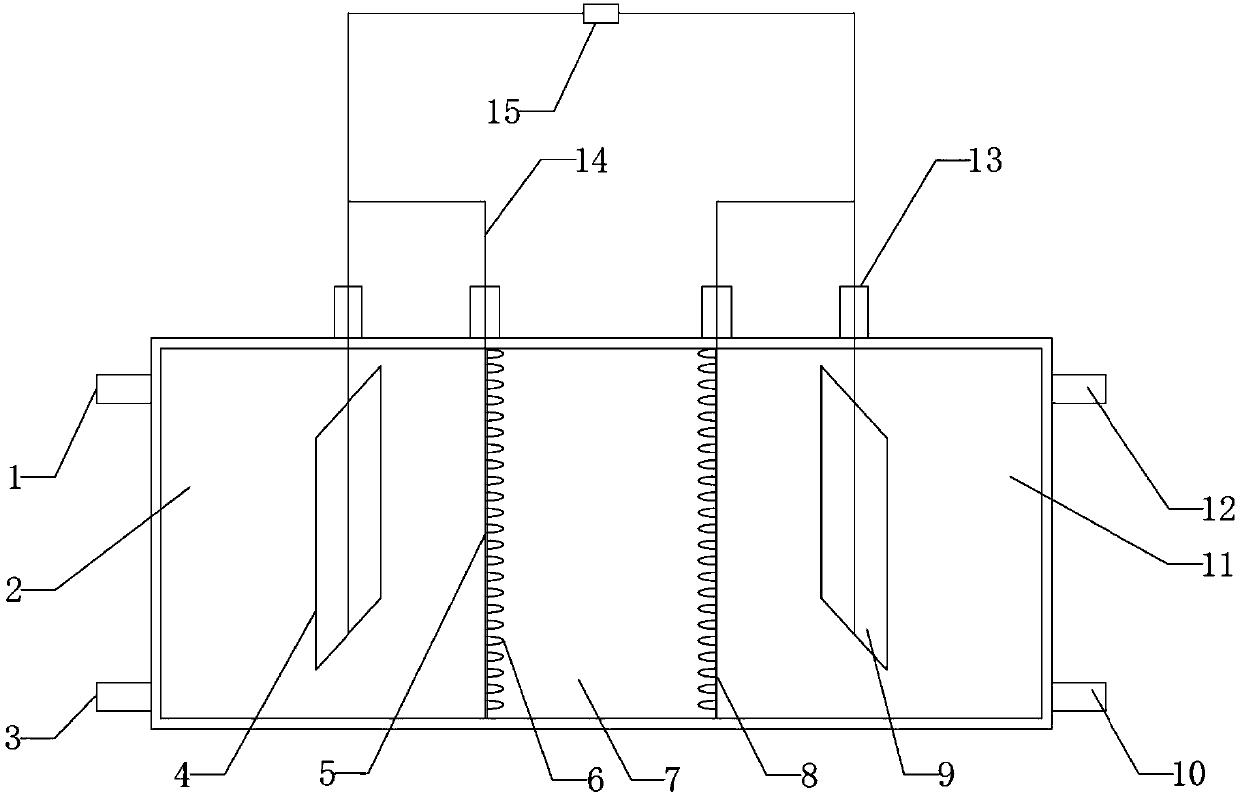

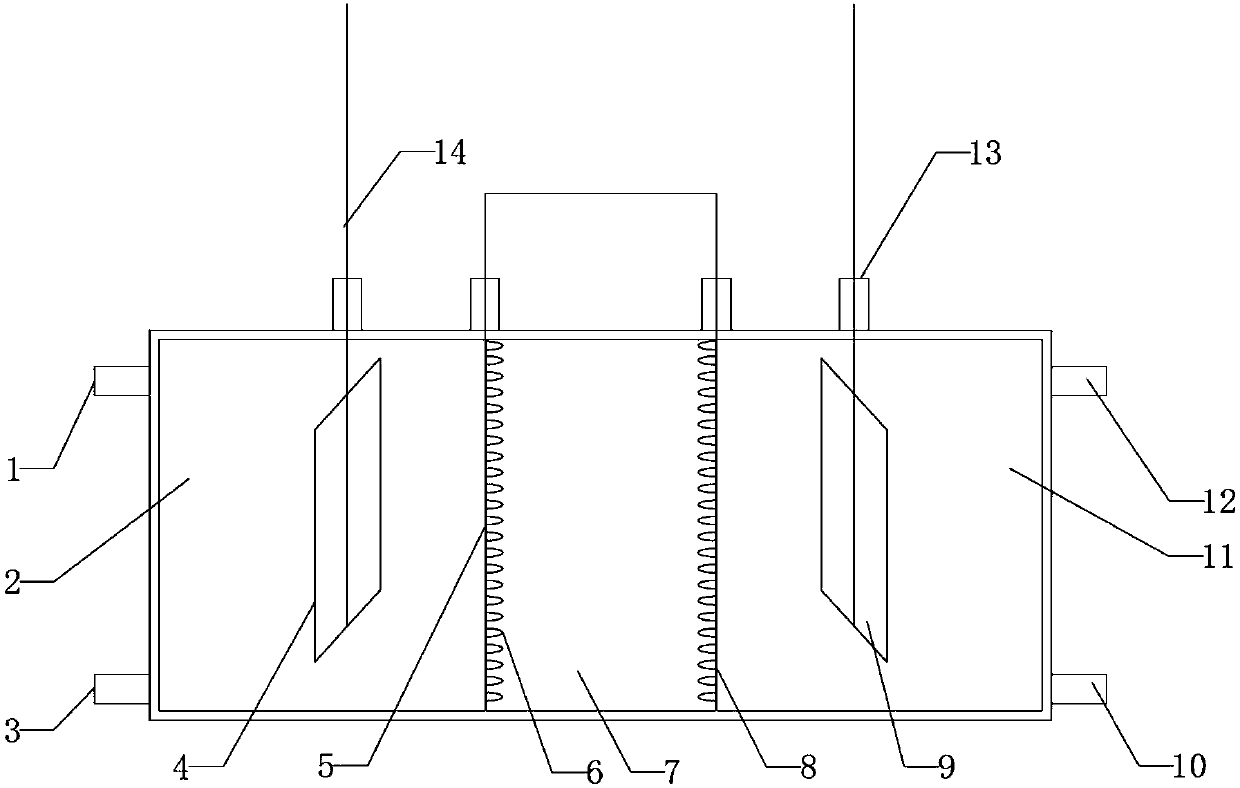

Image

Examples

Embodiment 1

[0061] Step 1. Fabrication of capacitive deionization electrode

[0062] The most important thing about capacitive deionization is the function of the electrode, and the function of the electrode mainly depends on the selection of the electrode material. The capacitive deionization electrode consists of two parts: one part is a titanium collector, and the other part is an activated carbon fiber. In order to better make the activated carbon fiber adhere to the titanium plate, the activated carbon fiber: acetylene black: polyvinylidene fluoride is used in a mass ratio of 8: After mixing at a ratio of 1:1, it is evenly coated on the surface of the titanium collector, and dried in an oven at 80°C to obtain the required electrode, that is, the capacitive deionization electrode.

[0063] Step 2, start-up of the microbial fuel cell;

[0064] Take an appropriate amount of fresh sludge from the secondary sedimentation tank of Qige Sewage Treatment Plant as the source of electricity-pr...

Embodiment 2

[0070] Step 1. Fabrication of capacitive deionization electrode

[0071] The most important thing about capacitive deionization is the function of the electrode, and the function of the electrode mainly depends on the selection of the electrode material. The capacitive deionization electrode consists of two parts: one part is titanium collector, and the other part is activated carbon fiber. In order to better make activated carbon fiber stick to the titanium plate, activated carbon fiber: acetylene black: polyvinylidene fluoride = 8:1: 1 After mixing, evenly coat on the surface of the titanium collector, and dry in an oven at 80°C to obtain the desired electrode.

[0072] Step 2. Start-up of the microbial fuel cell;

[0073] Take an appropriate amount of fresh sludge from the secondary sedimentation tank of Qige Sewage Treatment Plant as the source of electricity-producing microorganisms, pass the sludge through a 20-mesh sieve to filter out relatively large debris, and filte...

Embodiment 3

[0079] Step 1. Fabrication of capacitive deionization electrode

[0080] The most important thing about capacitive deionization is the function of the electrode, and the function of the electrode mainly depends on the selection of the electrode material. The capacitive deionization electrode consists of two parts: one part is titanium collector, and the other part is activated carbon fiber. In order to better make activated carbon fiber stick to the titanium plate, activated carbon fiber: acetylene black: polyvinylidene fluoride = 8:1: 1 After mixing, evenly coat on the surface of the titanium collector, and dry in an oven at 80°C to obtain the desired electrode.

[0081] Step 2. Start-up of the microbial fuel cell;

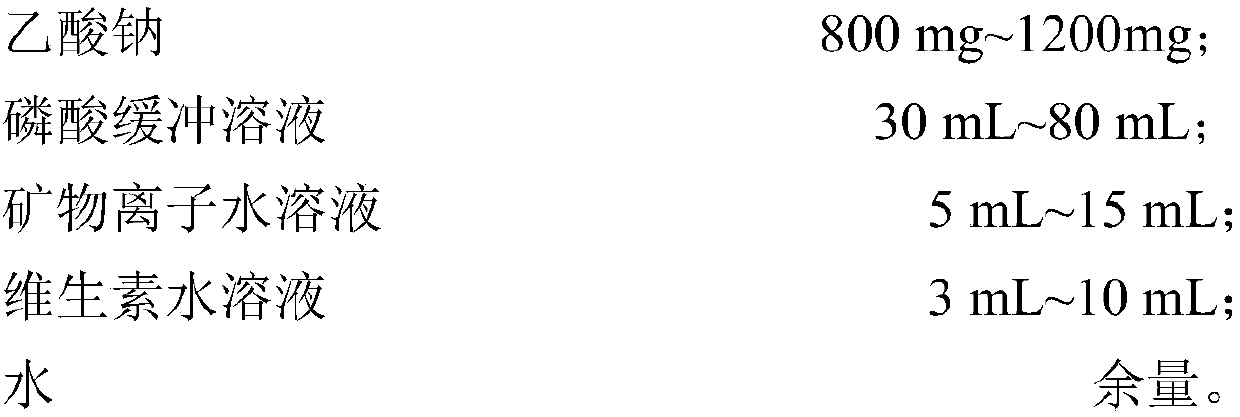

[0082] Use the commercially available strain Shewanella sp., No. 23931 (China Industrial Microorganism Culture Collection Management Center, CICC), to cultivate, take 20mL OD 600 Mix 1.0 bacteria solution and nutrient solution (1000mg sodium acetate, 50mL phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com