Passivator for farmland heavy metal contaminated soil, and preparation method and application of passivator

A technology that pollutes soil and heavy metals. It is applied in the direction of chemical instruments and methods, applications, and soil conditioning materials. It can solve problems such as affecting the environment and wasting resources, and achieve the effects of reducing application, increasing soil porosity, and increasing organic matter content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Formula 1: 100 parts of diatomite powder, 5 parts of ferrihydrite, 1 part of quicklime, and 8 parts of betel nut waste powder.

[0037] Formula 2: 100 parts of diatomite powder, 2 parts of apatite, 1 part of quicklime, and 8 parts of betel nut waste powder.

[0038]Formula 3: 100 parts of diatomite powder, 5 parts of ferrihydrite, 2 parts of apatite, 1 part of quicklime, and 8 parts of decomposed betel nut waste powder.

[0039] Formula 4: 100 parts of diatomite powder, 5 parts of ferrihydrite, 2 parts of apatite, 1 part of quicklime, and 8 parts of betel nut waste powder.

[0040] Formula 5: 100 parts of sepiolite powder, 3 parts of goethite, 3 parts of sodium phosphate, 2 parts of quicklime, 12 parts of betel nut waste powder.

[0041] Formula 6: 100 parts of bentonite powder, 8 parts of hematite, 1.5 parts of apatite, 2 parts of quicklime, and 6 parts of betel nut waste powder.

[0042] Above formula 1~6 is prepared into soil conditioner by following specific metho...

Embodiment 2

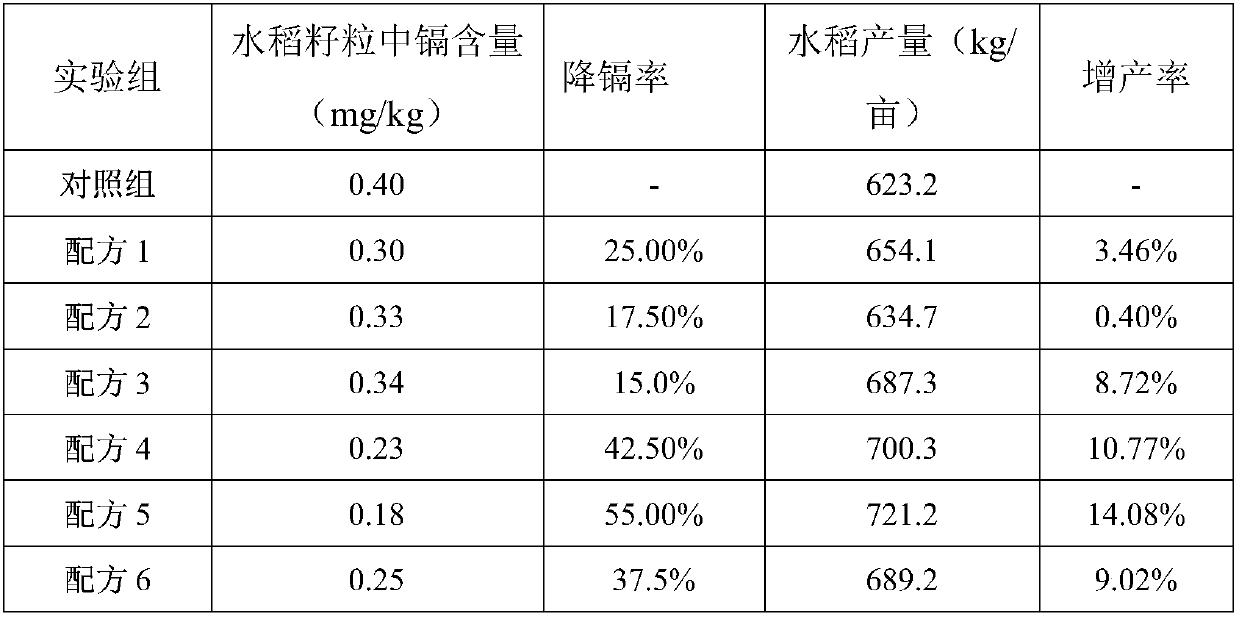

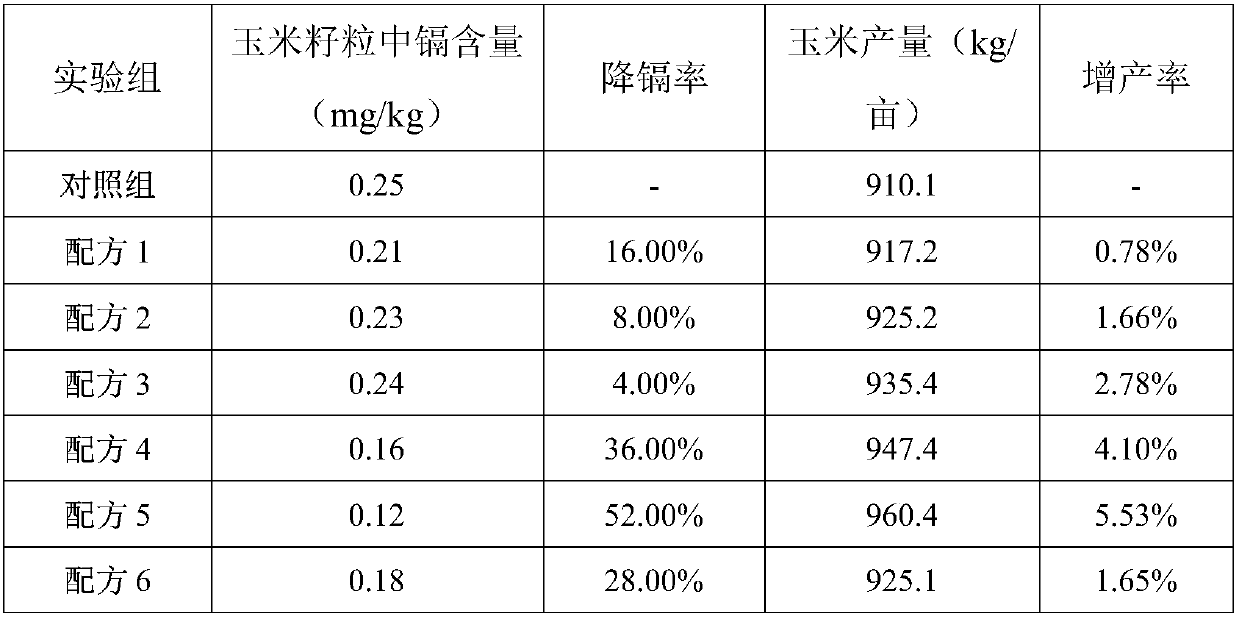

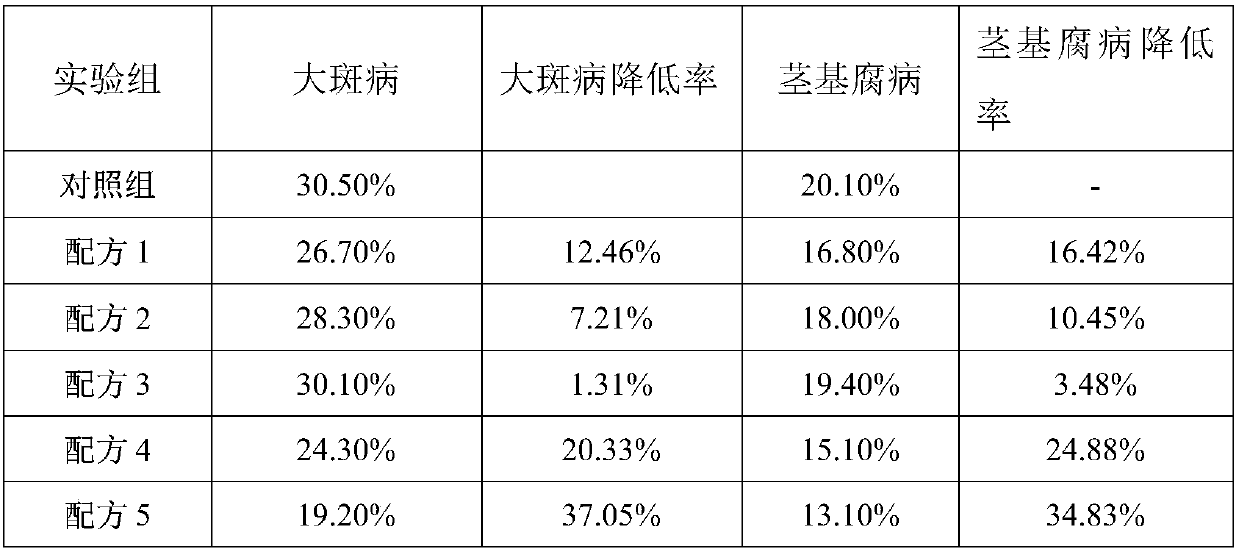

[0049] Field plot application test of the above formulations 1-6 soil remediation agents:

[0050] 1) Take the farmland polluted by heavy metals in a certain town in Hunan Province, and conduct a field plot experiment. The cadmium content in the soil is 0.62mg / kg, and the experimental material is rice.

[0051] The test field was divided into 28 test plots, with 7 treatments in total, and 4 parallels for each treatment. One treatment was used as the control group without adding soil remediation agent, and formulas 1 to 6 were all taken as one treatment. The area of the plot is 4m×5m, arranged randomly. At the beginning of the experiment, no fertilizer was applied to the test field, the field was plowed and leveled, and single-row and single-irrigation were implemented to prevent the spread of fertilizer and water between plots. Apply soil remediation agent to the corresponding plot for each treatment, and the soil passivation agent addition rate is 200kg / mu. The soil passiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com