Aquatic product low-temperature refrigeration device and method

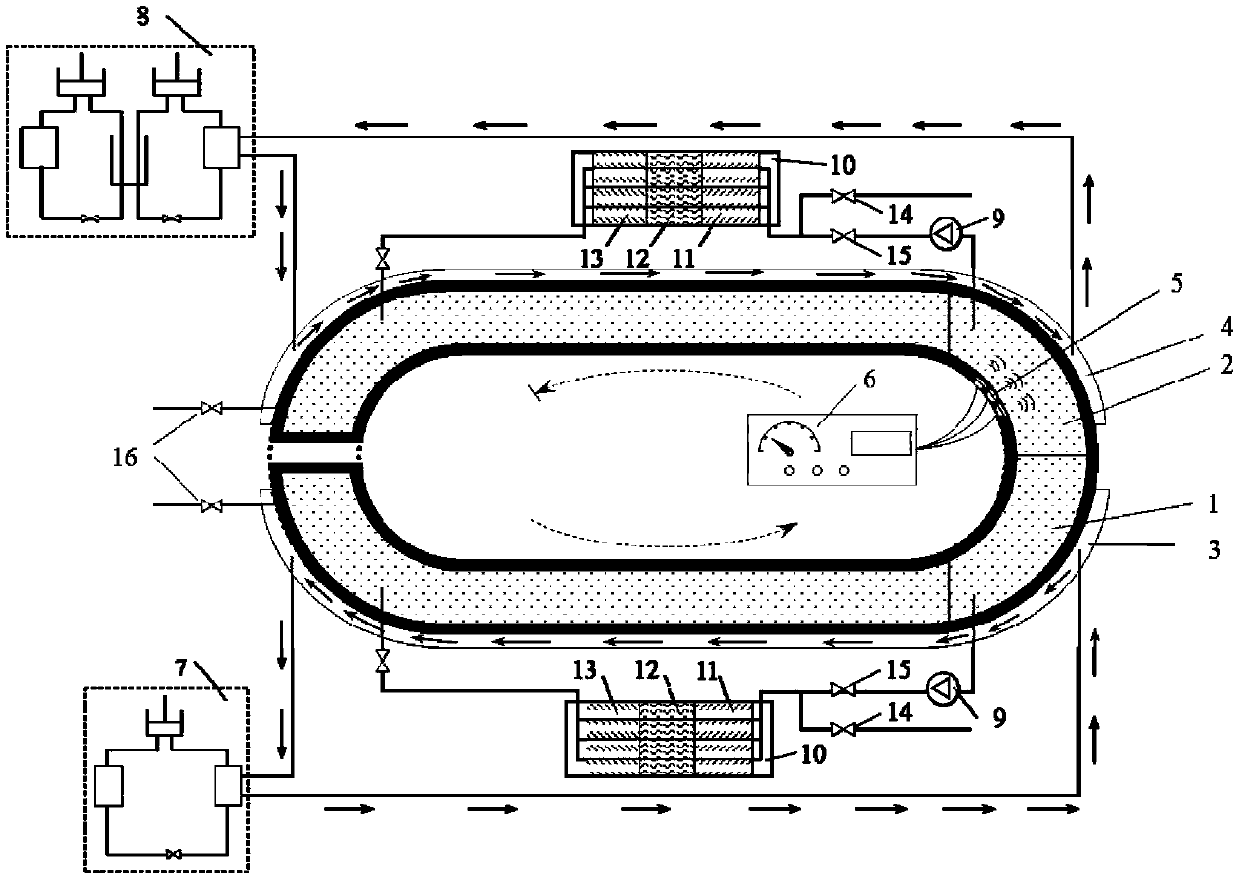

A technology for low-temperature freezing and aquatic products, which is applied in food freezing, meat/fish preservation through freezing/cooling, food ultrasonic treatment, etc. It can solve the problems of color change of frozen products, reduction of edible value of aquatic products, water loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

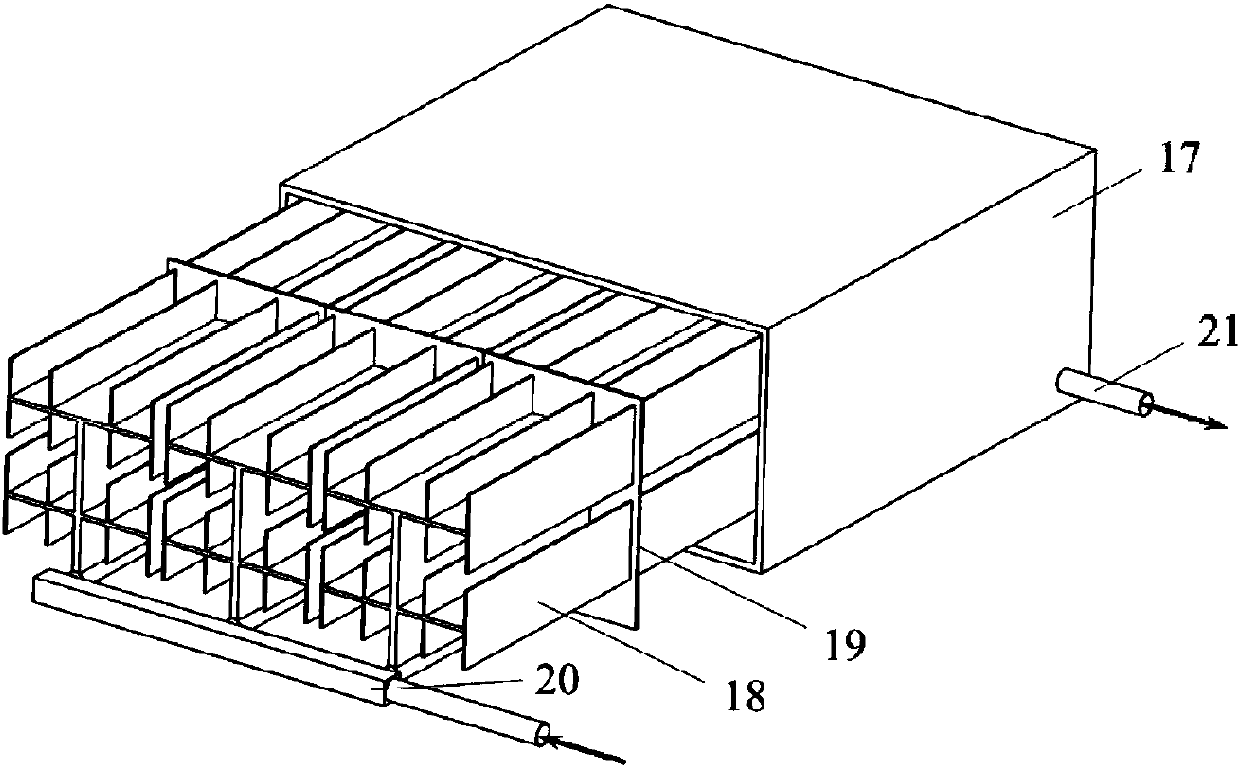

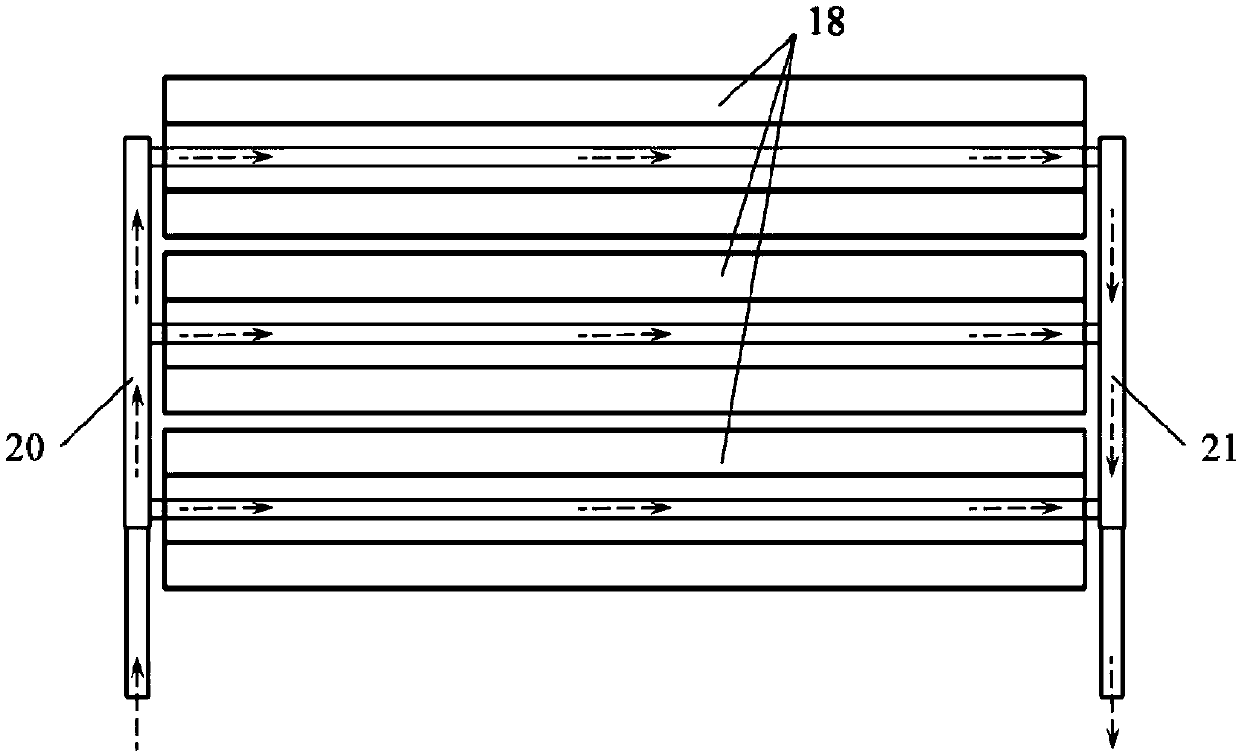

Method used

Image

Examples

Embodiment 1

[0043] The formula of the flash freezing liquid is as follows: 5% sodium chloride, 1% magnesium chloride, 9% ethanol, 8% glycerin, 4% chitin, and the rest is distilled water. The freezing point of the flash freezing liquid is -46°C.

[0044] Fill the prepared flash freezing liquid into the pre-cooling pool and freezing pool, and turn on the refrigeration unit to cool down the flash freezing liquid in the pre-cooling pool and freezing pool to -1°C and -45°C respectively. Turn on the ultrasonic assisted freezing system, the working conditions are: frequency 25kHz, power density 1.6W / cm 2 , work for 12s and stop for 4s. Slaughter and wash the fresh Japanese perch, cut the fish fillets, and divide 8 kg of fish fillets with a thickness of at least 1 cm into two equal portions. Take one piece of fish fillet from each of the two copies, insert a K-type thermocouple into its center and wrap the compensation line. Take one part of the fish fillets and place them in wire mesh baskets,...

Embodiment 2

[0046] The formula of the flash freezing liquid is as follows: 0.5% sodium chloride, 2% magnesium chloride, 5% ethanol, 10% glycerin, 2% chitin, and the rest is distilled water. The freezing point of the flash freezing liquid is -45°C.

[0047] Fill the prepared flash freezing liquid into the pre-cooling pool and freezing pool, and turn on the refrigeration unit to cool down the flash freezing liquid in the pre-cooling pool and freezing pool to -1°C and -44°C respectively. Turn on the ultrasonic assisted freezing system, the working conditions are: frequency 25kHz, power density 1.6W / cm 2 , work for 12s and stop for 4s. Wash the fresh geoduck and take out the mussel meat, remove the viscera, take 4kg of mussel meat with a center thickness of at least 1cm and divide it into two equal portions. Take one piece of clam meat from each of the two parts, insert a K-type thermocouple into its center and wrap the compensation line. Take one part of the mussel meat and place it in a w...

Embodiment 3

[0049] The formula of the flash freezing liquid is as follows: 8% sodium chloride, 0.1% magnesium chloride, 12% ethanol, 7% glycerin, 4% chitin, and the rest is distilled water. The freezing point of the flash freezing liquid is -48°C.

[0050] Fill the prepared flash freezing liquid into the pre-cooling pool and freezing pool, and turn on the refrigeration unit to cool down the flash freezing liquid in the pre-cooling pool and freezing pool to -1°C and -45°C respectively. Turn on the ultrasonic assisted freezing system, the working conditions are: frequency 25kHz, power density 1.6W / cm 2 , work for 12s and stop for 4s. Slaughter and wash fresh prawns, take out the shrimp meat, and divide 4kg of shrimp meat with a center thickness of at least 1cm into two equal portions. Take one piece of shrimp meat from each of the two parts, insert a K-type thermocouple into its center and wrap the compensation line. Take one part of the shrimp meat and put it in a wire mesh basket, hoist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com