Preparation technology of carp feed

A preparation process and carp feed technology, which is applied in animal feed, animal feed, food processing, etc., can solve the problems of large bait coefficient and low average weight gain rate, etc., achieve strong dispersion performance, improve effect, and increase average weight gain rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

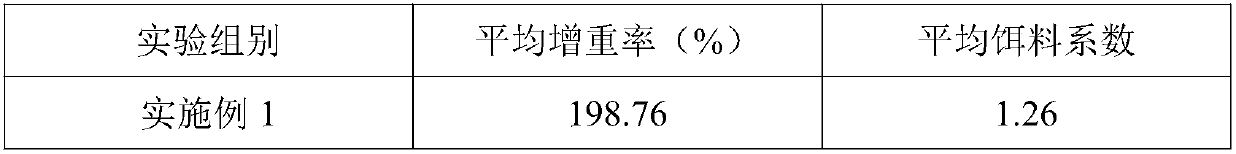

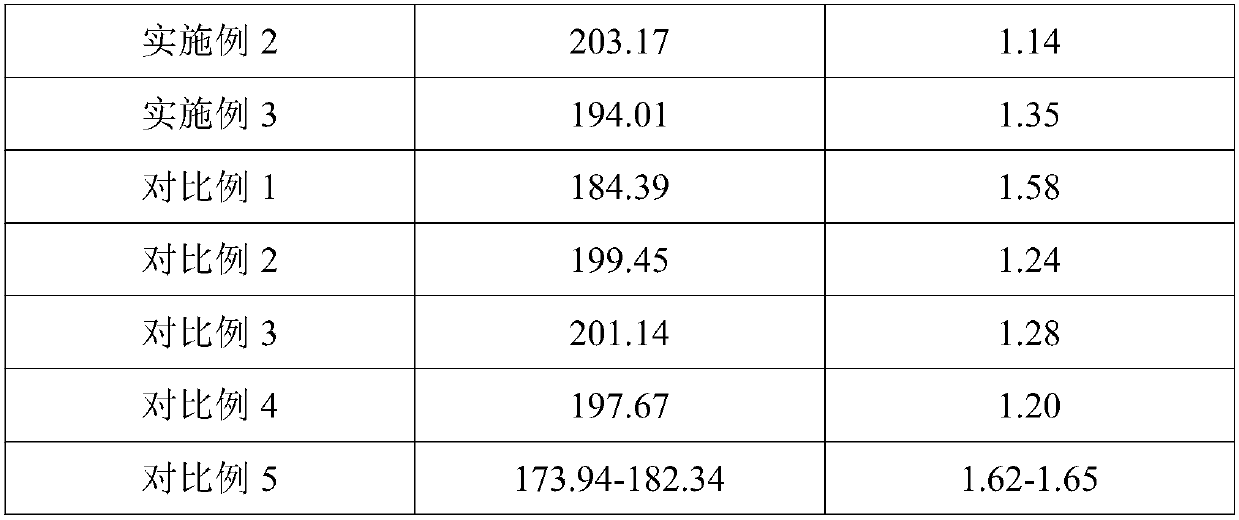

Examples

preparation example Construction

[0035] The preparation method of described carp feed comprises the following steps:

[0036] S1: Shrimp shell waste, wheat flour, tapioca starch, brewer's yeast, soybean meal, peanut meal, rapeseed cake, and corn flour were dried and crushed in parts by weight, passed through a 100-300-mesh sieve and mixed evenly to obtain a uniform mixture ;

[0037] S2: Add cooked egg protein, meat floss powder, non-starch polysaccharase, glutamine, probiotics, immune polysaccharide, traditional Chinese medicine food attractant, vitamin, additive A, Additive B, additive C, and 120-200 parts of water are mixed evenly again to prepare wet feed;

[0038] The preparation method of Chinese medicine food attractant described in step S2, comprises the following steps:

[0039] (a) removing water from Cortex Phellodendri, Magnolia Officinalis, Radix Pseudostellariae, Radix Glycyrrhiza, Pomegranate Peel, Dabupi Pi, malt, Panax notoginseng, dried tangerine peel by weight to ≤8%;

[0040] (b) Pulver...

Embodiment 1

[0044] A carp feed, in parts by weight, comprising the following raw materials: 32 parts of shrimp shell waste, 12 parts of wheat flour, 6 parts of tapioca starch, 7 parts of brewer's yeast, 6 parts of soybean meal, 5 parts of peanut meal, 4 parts of rapeseed cake , 3 parts of corn flour, 2 parts of boiled egg protein, 3 parts of meat floss powder, 1.2 parts of non-starch polysaccharide enzyme, 0.4 part of glutamine, 0.8 part of probiotics, 1 part of immune polysaccharide, 0.9 part of traditional Chinese medicine food attractant, 1.8 parts of vitamins, 0.6 parts of additive A, 0.8 parts of additive B, 0.3 parts of additive C;

[0045] The additive A includes the following raw materials in parts by weight: 15 parts of potassium carboxymethylcellulose, 8 parts of potassium alginate, and 10 parts of dextrin;

[0046] The additive B is potassium 5-nitroguaiacol;

[0047] The additive C is 1,3-di-o-tolylguanidine;

[0048] The non-starch polysaccharidase is mannanase;

[0049] The...

Embodiment 2

[0061] A carp feed, in parts by weight, comprising the following raw materials: 42 parts of shrimp shell waste, 14 parts of wheat flour, 8 parts of tapioca starch, 10 parts of brewer's yeast, 10 parts of soybean meal, 7 parts of peanut meal, 5 parts of rapeseed cake , 4 parts of corn flour, 4 parts of boiled egg protein, 5 parts of meat floss powder, 2 parts of non-starch polysaccharide enzyme, 1 part of glutamine, 1.5 parts of probiotics, 2 parts of immune polysaccharide, 2 parts of traditional Chinese medicine food attractant, 2 parts of vitamins, 0.9 parts of additive A, 1.6 parts of additive B, 0.4 parts of additive C;

[0062] The additive A includes the following raw materials in parts by weight: 22 parts of potassium carboxymethylcellulose, 10 parts of potassium alginate, and 14 parts of dextrin;

[0063] The additive B is potassium 5-nitroguaiacol;

[0064] The additive C is 1,3-di-o-tolylguanidine;

[0065] The non-starch polysaccharidase is mannanase;

[0066] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com