Preparation method of composite metal oxide loaded catalyst and application of catalyst to field of waste gas treatment

A composite metal and oxide technology, applied in the field of industrial waste gas treatment and waste gas treatment, can solve few problems, and achieve the effects of avoiding secondary pollution, clean and environmentally friendly process methods, and simple and easy preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

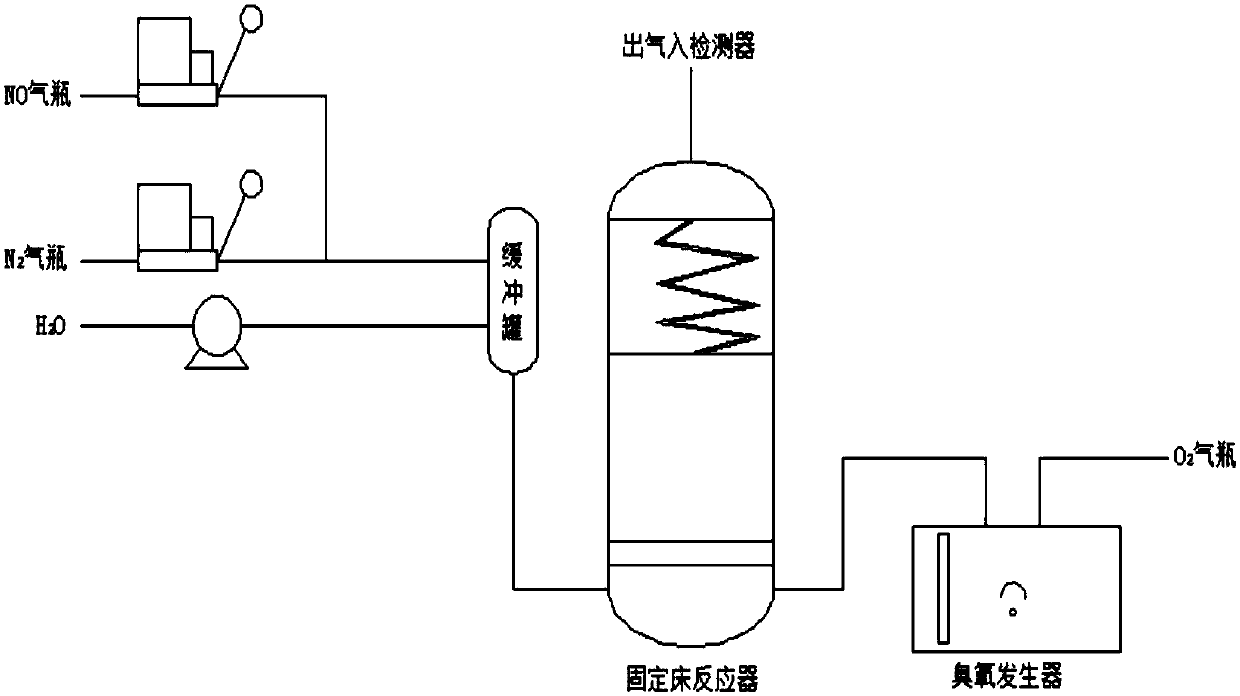

Method used

Image

Examples

Embodiment 1

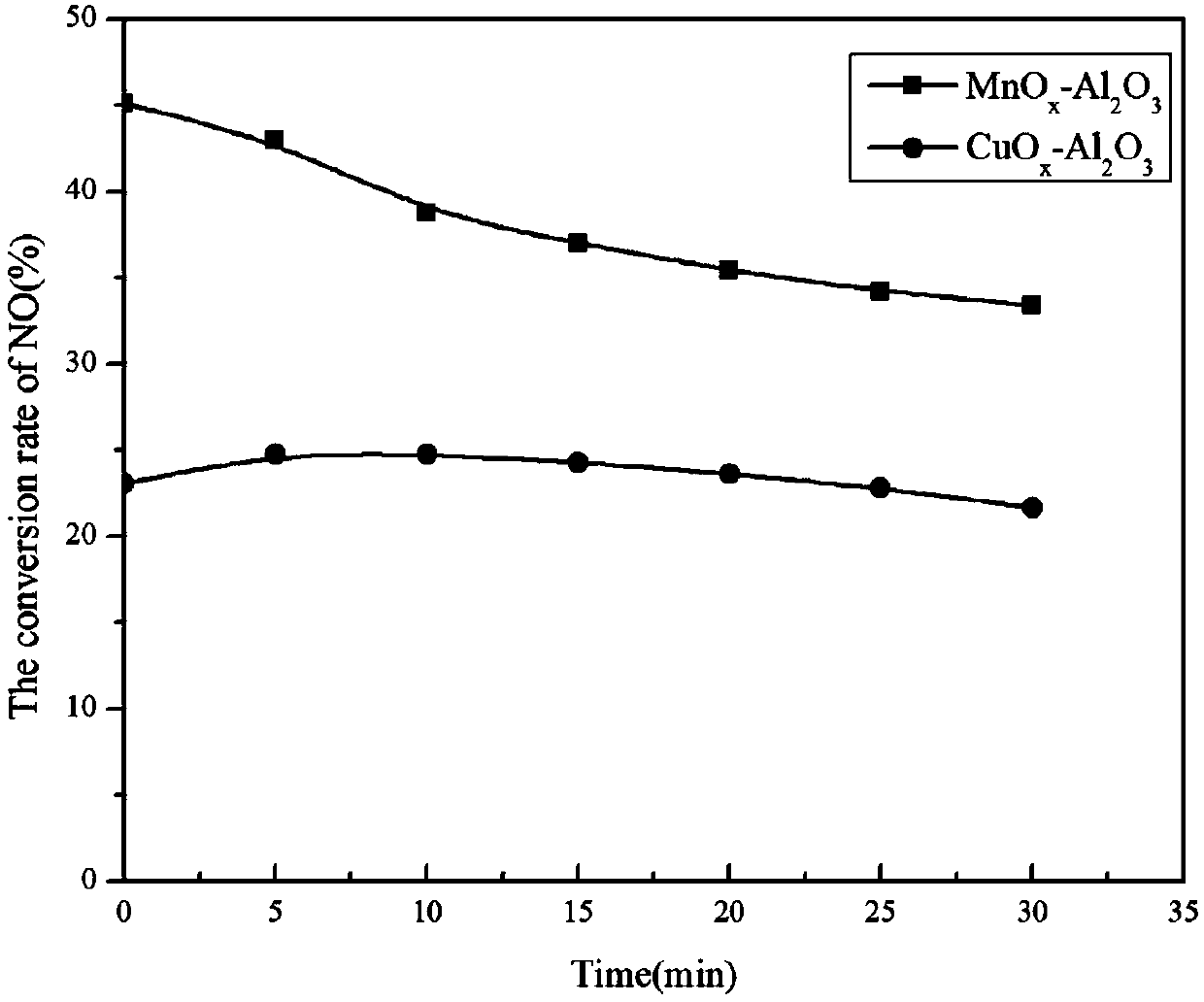

[0040] Example 1: MnO x -Al 2 o 3 Catalyst Preparation and Application of Catalytic Ozone Oxidation Performance

[0041] Select γ-Al of 1~2mm 2 o 3 The small ball is used as the catalyst carrier, washed twice with deionized water, then soaked overnight with 0.10mol / L dilute hydrochloric acid, finally washed with deionized water until the effluent is neutral, and dried at 100±2°C to obtain the activation treated γ-Al 2 o 3 pellets; activated γ-Al 2 o 3 The pellets use an appropriate amount of 50% Mn(NO 3 ) 2 The solution was impregnated with an equal volume, ultrasonicated for 2 hours, dried in an oven at 105°C for 2.5 hours, and then roasted at 500°C for 4 hours to obtain MnO x -Al 2 o 3 catalyst.

[0042] 10g of prepared MnO x -Al 2 o 3The catalyst is loaded into the reaction device, and the simulated flue gas containing 500ppmNO is passed through. The flue gas flow rate is set at 1L / min, the relative humidity of the flue gas is 10%, the reaction temperature i...

Embodiment 2

[0043] Example 2: CuO x -Al 2 o 3 Catalyst Preparation and Application of Catalytic Ozone Oxidation Performance

[0044] Select γ-Al of 1~2mm 2 o 3 The small ball is used as the catalyst carrier, washed twice with deionized water, then soaked overnight with 0.10mol / L dilute hydrochloric acid, finally washed with deionized water until the effluent is neutral, and dried at 100±2°C to obtain the activation treated γ-Al 2 o 3 pellets; activated γ-Al 2 o 3 The pellets were filled with an appropriate amount of Cu(NO 3 ) 2 The solution was impregnated with an equal volume, ultrasonicated for 2 hours, dried in an oven at 105°C for 2.5 hours, and then roasted at 500°C for 4 hours to obtain CuO x -Al 2 o 3 catalyst.

[0045] 10g of prepared CuO x -Al 2 o 3 The catalyst is loaded into the reaction device, and the simulated flue gas containing 500ppmNO is passed through. The flue gas flow rate is set at 1L / min, the relative humidity of the flue gas is 10%, the reaction tem...

Embodiment 3

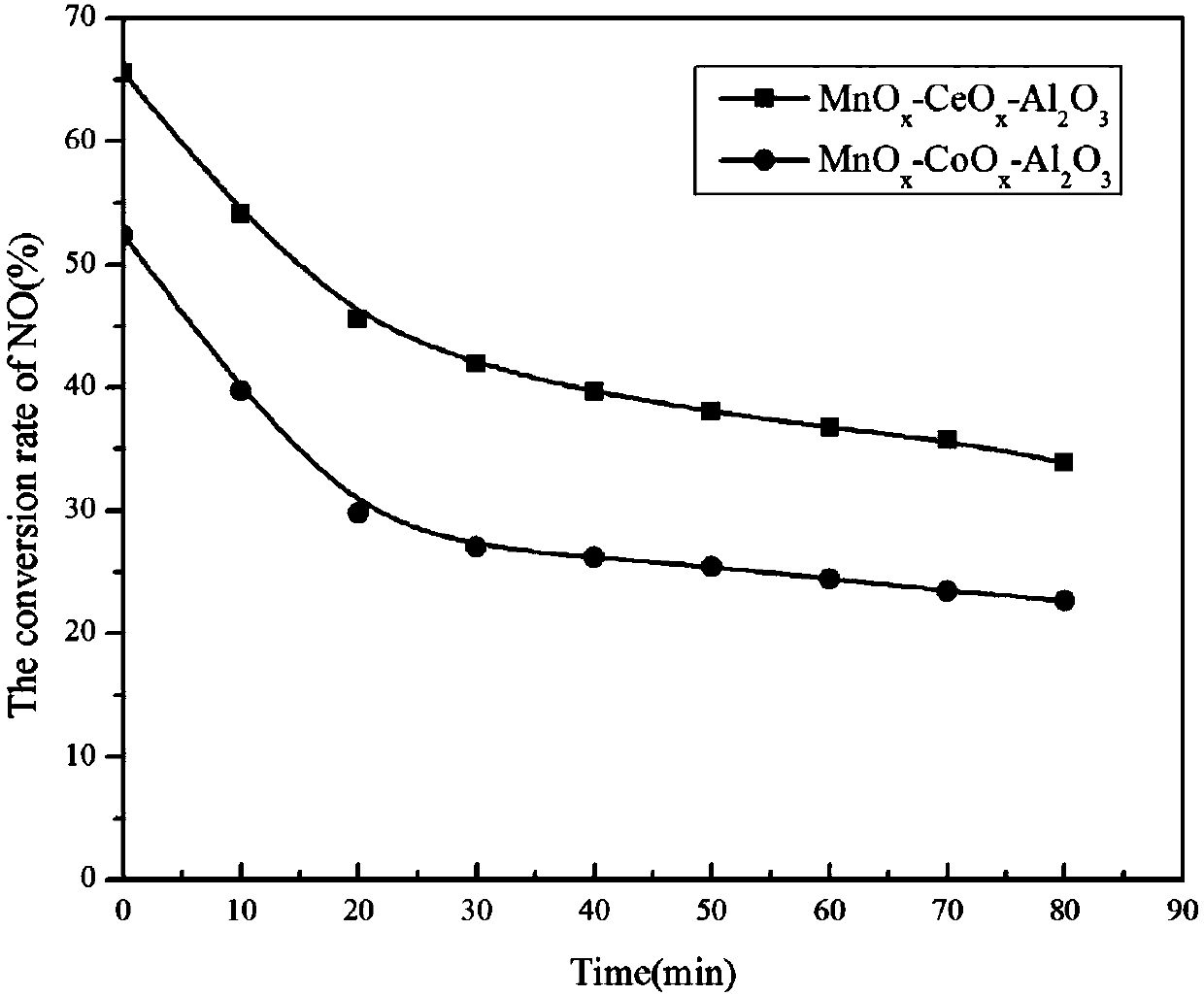

[0046] Example 3: MnO x -CeO x -Al 2 o 3 Catalyst Preparation and Application of Catalytic Ozone Oxidation Performance

[0047] Select γ-Al of 1~2mm 2 o 3 The small ball is used as the catalyst carrier, washed twice with deionized water, then soaked overnight with 0.10mol / L dilute hydrochloric acid, finally washed with deionized water until the effluent is neutral, and dried at 100±2°C to obtain the activation treated γ-Al 2 o 3 pellets; activated γ-Al 2 o 3 The pellets were filled with an appropriate amount of Mn(NO 3 ) 2 and Ce(NO 3 ) 2 The mixed solution is impregnated with equal volume, ultrasonicated for 2 hours, dried in an oven at 105°C for 2.5 hours, and then roasted at 500°C for 4 hours to obtain MnO x -CeO x -Al 2 o 3 catalyst.

[0048] 10g of prepared MnO x -CeO x -Al 2 o 3 The catalyst is loaded into the reaction device, and the simulated flue gas containing 500ppmNO is passed through. The flue gas flow rate is set at 1L / min, the relative humid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com