Elastic cotton-linen-like polyester fiber and preparation method thereof

A polyester fiber and cotton-like technology, which is applied in fiber treatment, fiber chemical characteristics, melt spinning, etc., can solve the problems of inability to balance moisture permeability and wrinkle resistance, and achieve excellent wrinkle resistance, good moisture permeability, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of elastic cotton-linen-like polyester fiber, the steps are as follows:

[0055] (1) The polyester melt is measured, extruded through a composite spinneret, cooled, oiled and wound to obtain POY filaments. Matting agents are dispersed in the polyester melts, and the matting agents are amorphous titanium dioxide and The mixture of amorphous silicon dioxide, the content of matting agent in polyester is 1.25wt%, and the content of amorphous silicon dioxide in matting agent is 22.5wt%. The spinning process parameters of POY silk are as follows: Outlet temperature: 285°C; cooling air temperature: 22°C; winding speed: 2700m / min;

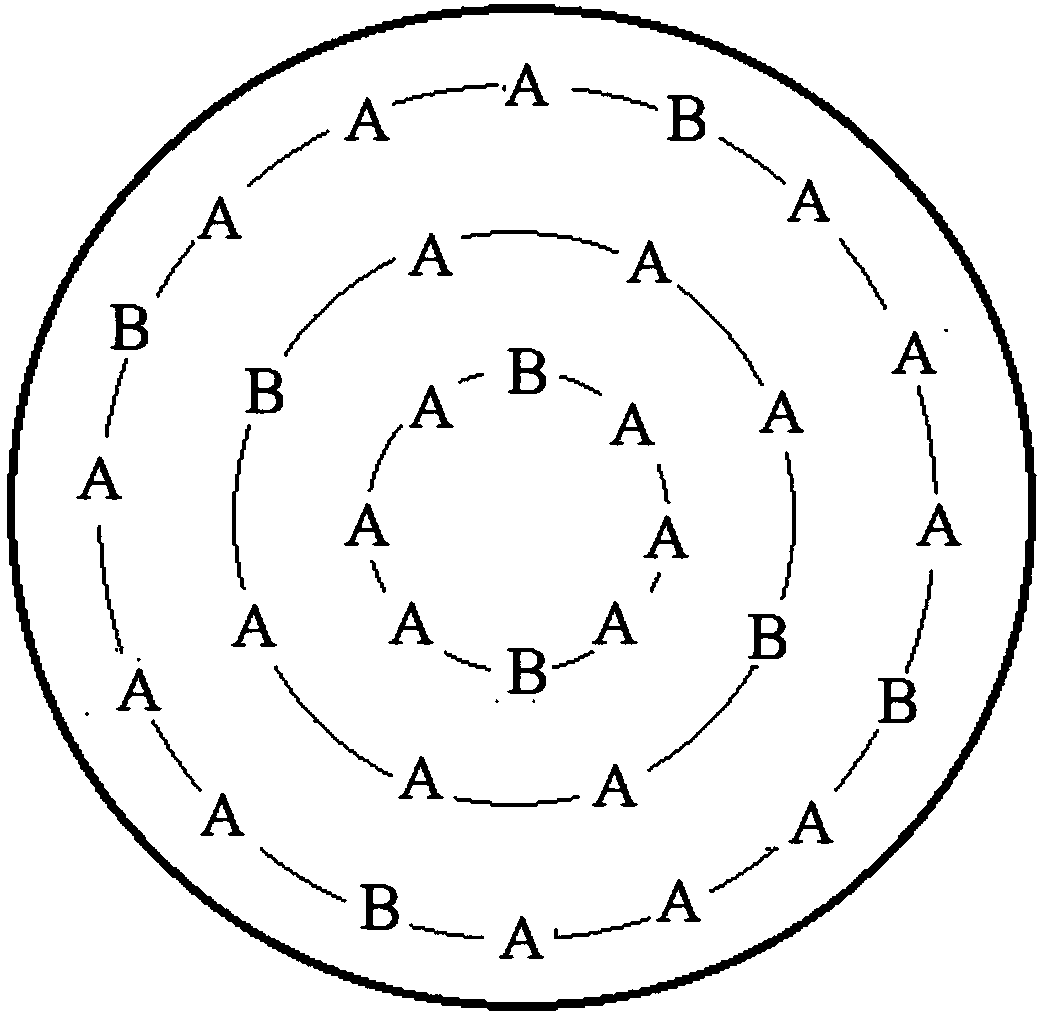

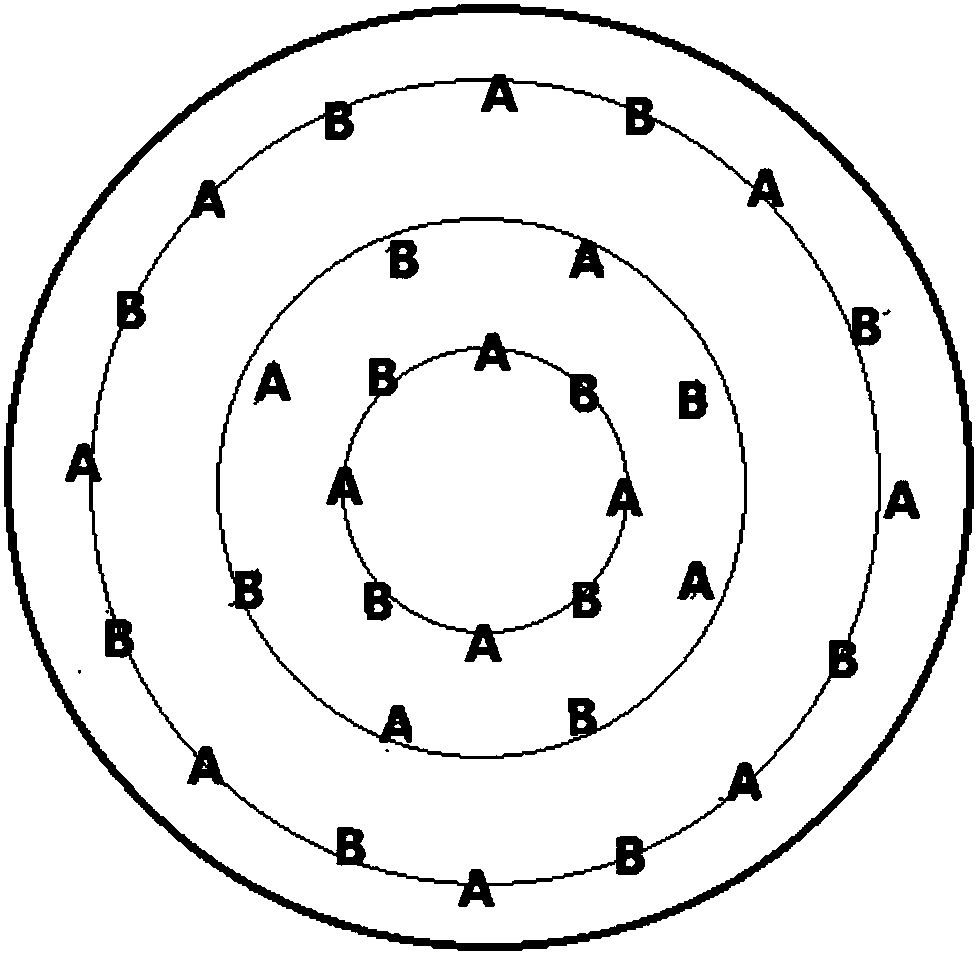

[0056] Among them, the composite spinneret is provided with cross-shaped spinneret holes and circular spinneret holes at the same time, and the ratio of the micropore length of the cross-shaped spinneret holes to the circular spinneret holes is equal to the ratio of the cross-shaped spinneret holes to the circular spinneret hole...

Embodiment 2

[0060] A preparation method of elastic cotton-linen-like polyester fiber, the steps are as follows:

[0061] (1) The polyester melt is measured, extruded through a composite spinneret, cooled, oiled and wound to obtain POY filaments. A matting agent is dispersed in the polyester melt, and the matting agent is calcium carbonate and amorphous The mixture of silicon dioxide, the content of matting agent in polyester is 1wt%, the content of amorphous silicon dioxide in matting agent is 15wt%, the spinning process parameter of POY silk is as follows: the temperature of extruding: 280°C; cooling air temperature: 20°C; winding speed: 2500m / min;

[0062] Among them, the composite spinneret is provided with cross-shaped spinneret holes and circular spinneret holes at the same time, and the ratio of the micropore length of the cross-shaped spinneret holes to the circular spinneret holes is equal to the ratio of the cross-shaped spinneret holes to the circular spinneret holes. The produ...

Embodiment 3

[0066] A preparation method of elastic cotton-linen-like polyester fiber, the steps are as follows:

[0067] (1) The polyester melt is measured, extruded through a composite spinneret, cooled, oiled and wound to obtain POY filaments. A matting agent is dispersed in the polyester melt, and the matting agent is calcium carbonate and amorphous The mixture of silicon dioxide, the content of matting agent in polyester is 1.5wt%, the content of amorphous silicon dioxide in matting agent is 30wt%, the spinning process parameter of POY silk is as follows: the temperature of extruding : 290°C; Cooling air temperature: 25°C; Winding speed: 3000m / min;

[0068] Among them, the composite spinneret is provided with cross-shaped spinneret holes and circular spinneret holes at the same time, and the ratio of the micropore length of the cross-shaped spinneret holes to the circular spinneret holes is equal to the ratio of the cross-shaped spinneret holes to the circular spinneret holes. The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com