Porous polymer adsorption material containing triazine ring and azo bond functional groups, and porous polymer catalysis material, and preparation methods and applications thereof

A porous polymer and adsorption material technology, applied in the field of adsorption materials and catalytic materials, can solve the problems of toxic and side effects compounds, unfavorable industrial production promotion, and many side reactions, so as to improve affinity, load stability, and cheap raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

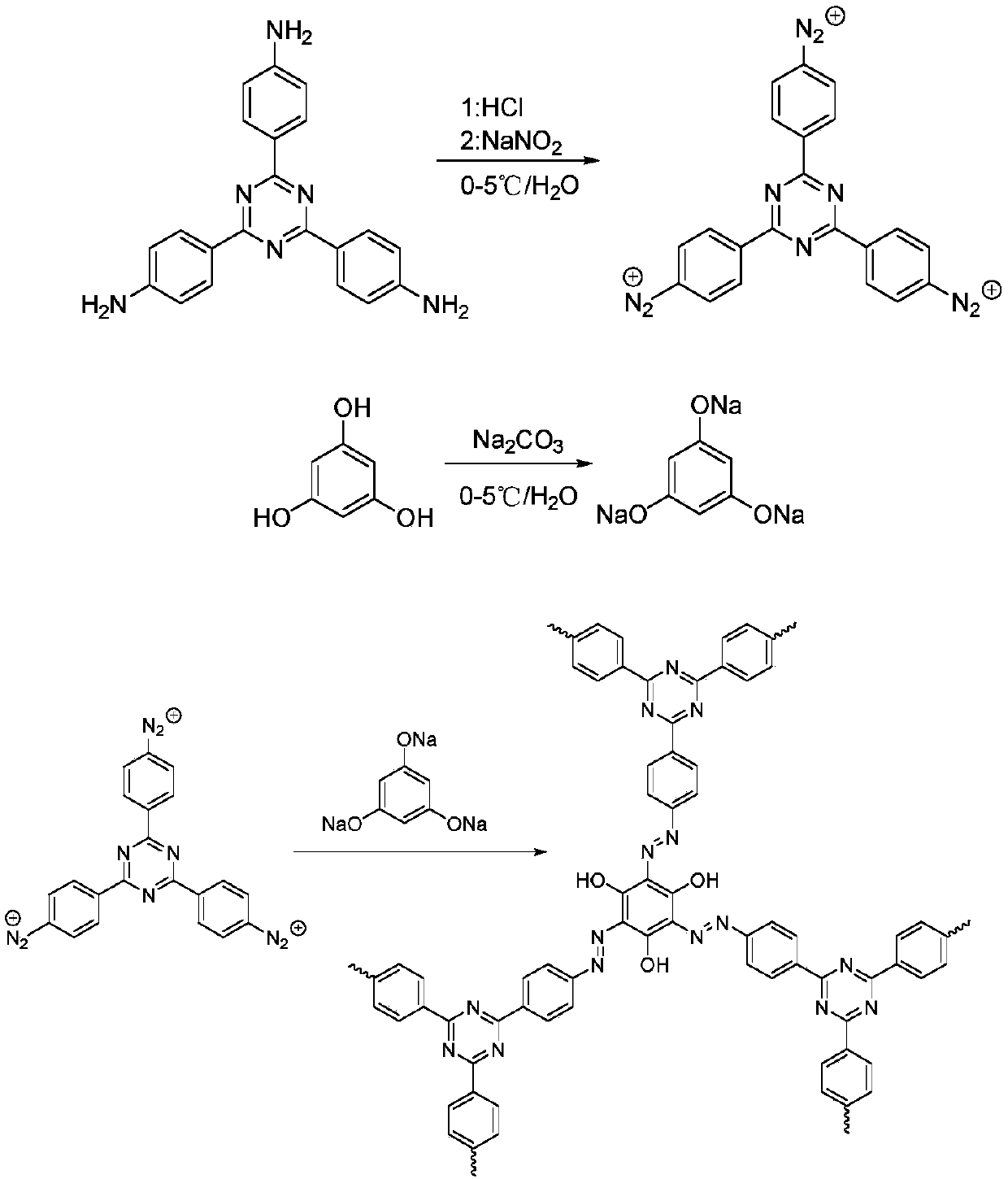

[0051] Step (1): Preparation of Porous Polymer Adsorbent Material Containing Triazine Ring and Azo Bond Functional Group

[0052] Weigh 0.35g of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine into 60mL of deionized water, add 0.7mL of concentrated hydrochloric acid, and continue stirring for 15min under ice bath conditions to obtain dilute For a clear yellow solution, add 30mL aqueous solution containing 0.2g sodium nitrite dropwise, the solution turns brownish black, continue to stir for 25min, then adjust the pH of the solution to neutral with sodium carbonate solution, add 30mL containing 0.12g phlorotriphenol dropwise and 0.3g of sodium carbonate aqueous solution, the whole process was kept in ice bath, then kept stirring at room temperature for 24h, filtered to obtain the crude product, washed successively with tetrahydrofuran, dichloromethane, methanol to obtain the crude product, after vacuum drying to obtain the three-containing Porous polymer adsorption materials with funct...

Embodiment 2

[0059] Step (1): Preparation of Porous Polymer Adsorbent Material Containing Triazine Ring and Azo Bond Functional Group

[0060] Weigh 0.35g of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine into 60mL of deionized water, add 0.7mL of concentrated hydrochloric acid, and continue stirring for 15min under ice bath conditions to obtain dilute For a clear yellow solution, add 30mL aqueous solution containing 0.2g sodium nitrite dropwise, the solution turns brownish black, continue stirring for 25min, then adjust the pH of the solution to neutral with sodium carbonate solution, add 30mL containing 0.16g p-diphenol dropwise and 0.3g of sodium carbonate aqueous solution, the whole process was kept in ice bath, then kept stirring at room temperature for 24h, filtered to obtain the crude product, washed successively with tetrahydrofuran, dichloromethane, methanol to obtain the crude product, after vacuum drying to obtain the three-containing Porous polymer adsorption materials with functiona...

Embodiment 3

[0066] Step (1): the recovery of embodiment 1 catalyst

[0067] The reaction liquid in step (3) of Example 1 was filtered, and the obtained solid was washed with absolute ethanol (4×40 ml) until the filtrate was colorless, and dried in a vacuum oven at 50° C. for 24 h.

[0068]Step (2): Catalyzing carbon dioxide and propylene oxide with the catalyst that reclaims to generate propylene carbonate

[0069] Take by weighing 0.6g propylene oxide, 225mgTBAB, the porous polymer catalytic material containing triazine ring and azo bond functional group reclaimed in the 20mg step (1) in the reactor liner, after mixing, pass into carbon dioxide gas, then Seal the reactor and react at 100°C and 150r / min for 1 hour. After the reaction, cool the reactor to room temperature, open the reactor, and add 1g of 1,1',2,2'-tetrachloro Methane was used as an internal standard, and then the reaction yield was calculated by testing 1H NMR spectrum.

[0070] Step (3): the catalyst after the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com