Method for preparing a mesoporous Ag2O/TiO2 composite material

A composite material and mesoporous technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as photocatalysis or low energy conversion efficiency, and achieve good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

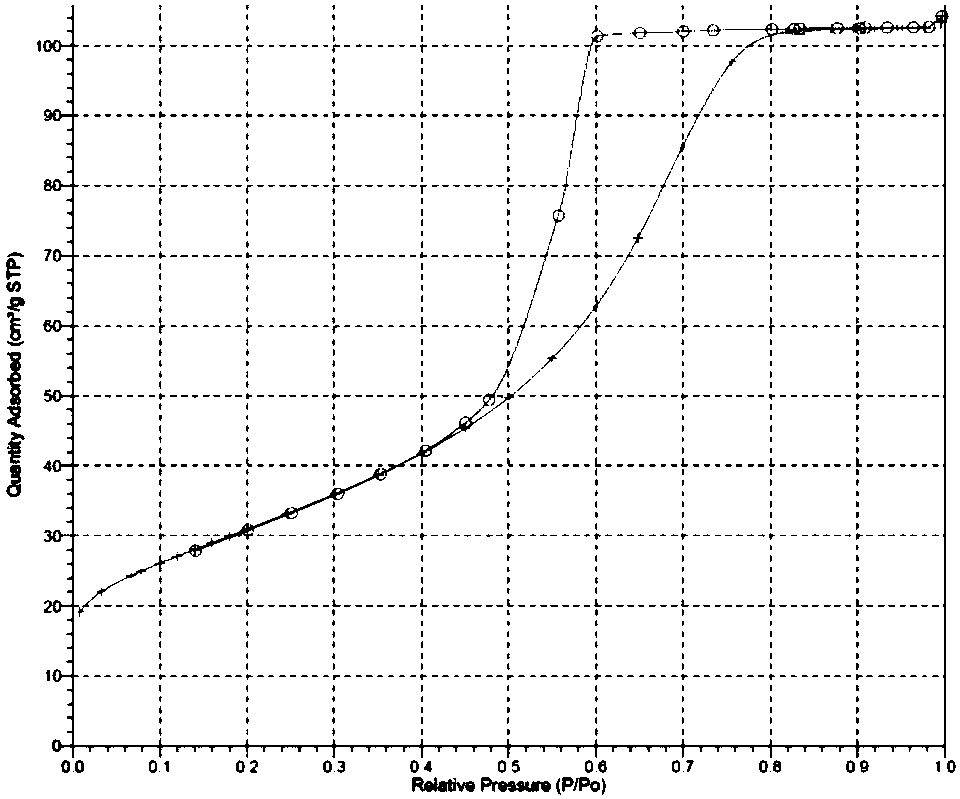

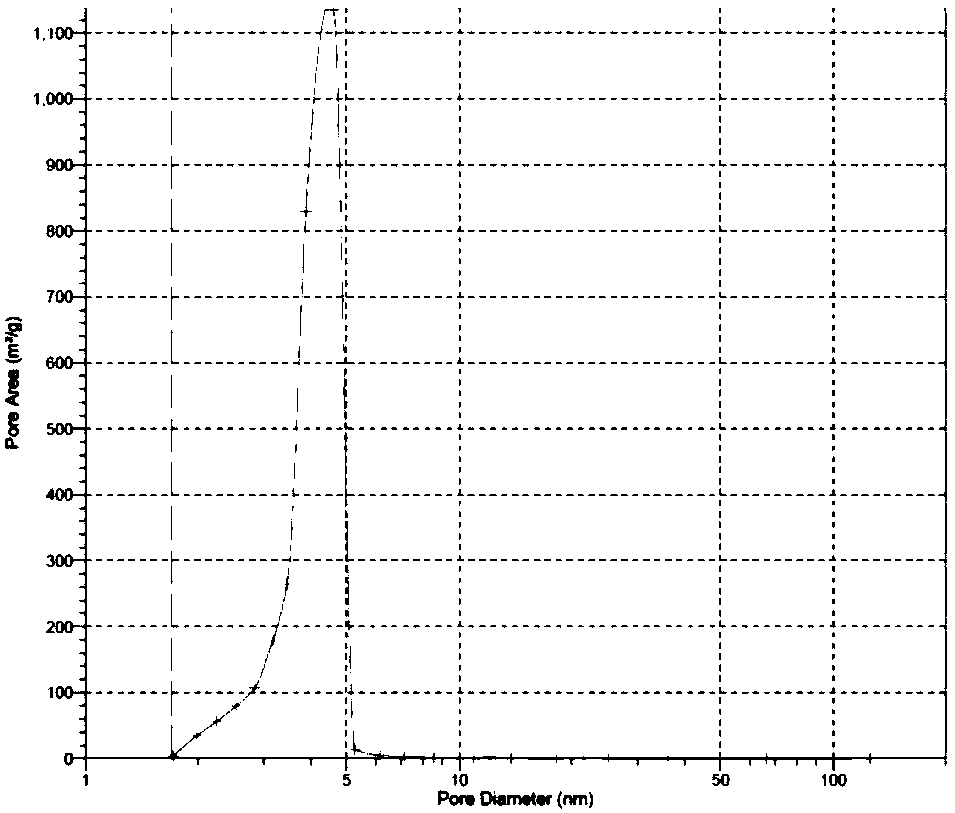

Image

Examples

Embodiment 1

[0029] Add CTAB and P123 to water at a molar ratio of 1:1, add it to the mixture of ethanol and hydrochloric acid, and stir in a water bath at 40°C to dissolve it. After 1 hour, a good amount of TBOT (variable 1) was added, and after 1 hour, a prefabricated silver nitrate aqueous solution (variable 2) was added dropwise. After 1 hour of heat preservation in a water bath, the stirring was stopped, and the mixture was transferred into a reaction kettle, and subjected to hydrothermal reaction in an oven at 100°C. After 24 hours, it was suction filtered and dried in an oven. The samples were heated from room temperature to 400°C at 1.5°C / min and kept at 400°C for 5 hours to obtain TAg series samples.

[0030] Calcination process: in air atmosphere, after raising to 100°C at a speed of 1.5-2°C / min, continue to raise to 450°C at a speed of 1.5-2°C / min and keep for 5 hours. Finally, after cooling down to 50°C at a rate of 2-3°C / min, the calcined sample was taken out.

Embodiment 2

[0032] Add CTAB and P123 to water at a molar ratio of 5:1, add to the mixture of ethanol and hydrochloric acid, and stir in a water bath at 40°C to dissolve. After 1 hour, a good amount of TBOT (variable 1) was added, and after 1 hour, a prefabricated silver nitrate aqueous solution (variable 2) was added dropwise. After 1 hour of heat preservation in a water bath, the stirring was stopped, and the mixture was transferred into a reaction kettle, and subjected to hydrothermal reaction in an oven at 100°C. After 24 hours, it was suction filtered and dried in an oven. The samples were heated from room temperature to 400°C at 1.5°C / min and kept at 400°C for 5 hours to obtain TAg series samples.

[0033] Calcination process: in air atmosphere, after raising to 100°C at a speed of 1.5-2°C / min, continue to raise to 450°C at a speed of 1.5-2°C / min and keep for 5 hours. Finally, after cooling down to 50°C at a rate of 2-3°C / min, the calcined sample was taken out.

Embodiment 3

[0035] Add CTAB and P123 to water at a molar ratio of 10:1, add it to the mixture of ethanol and hydrochloric acid, and stir in a water bath at 40°C to dissolve it. After 1 hour, a good amount of TBOT (variable 1) was added, and after 1 hour, a prefabricated silver nitrate aqueous solution (variable 2) was added dropwise. After 1 hour of heat preservation in a water bath, the stirring was stopped, and the mixture was transferred into a reaction kettle, and subjected to hydrothermal reaction in an oven at 100°C. After 24 hours, it was suction filtered and dried in an oven. The samples were heated from room temperature to 400°C at 1.5°C / min and kept at 400°C for 5 hours to obtain TAg series samples.

[0036] Calcination process: in air atmosphere, after raising to 100°C at a speed of 1.5-2°C / min, continue to raise to 450°C at a speed of 1.5-2°C / min and keep for 5 hours. Finally, after cooling down to 50°C at a rate of 2-3°C / min, the calcined sample was taken out. Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com