Production method of high-yield potassium iodate

A production method and technology of potassium iodate, applied in the directions of iodine oxygen compounds and the like, can solve the problems of high absorption pressure of tail gas, ineffective utilization, large energy consumption, etc., to reduce environmental protection pressure, improve reaction efficiency and reaction speed, avoid sublimation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

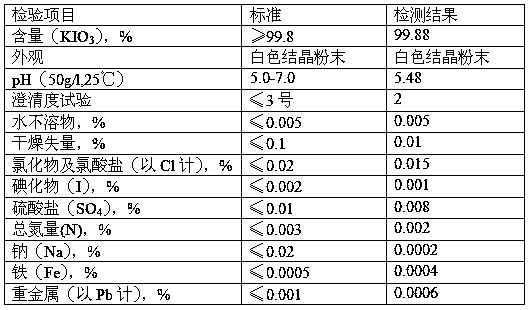

Embodiment 1

[0014] (1) Add 42Kg of potassium iodide to 50L of water, stir to dissolve, add 250ml of sulfuric acid, dropwise add 100L of 30wt% hydrogen peroxide, control the reaction temperature at 55°C, and add dropwise until the resulting yellow solution fades to colorless;

[0015] (2) Stir the reaction for 1 hour, adjust the pH of the reaction solution to 7.5 with 40% potassium hydroxide solution, raise the temperature to 90-100°C, continue to keep warm and stir the reaction until the total volume is about 60L, stop heating, and cool the reaction solution Centrifuge and dry the crystals to room temperature to obtain crude potassium iodate. The mother liquor is concentrated at 90-100°C to a small amount of crystallization, then cooled and crystallized, and the solid is incorporated into the crude potassium iodate.

[0016] (3) Add 42Kg of the obtained potassium iodate crude product to the temperature and dissolve it, adjust the specific gravity of the solution to d=1.17, keep the tempera...

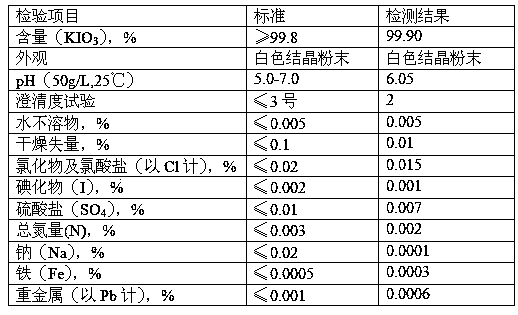

Embodiment 2

[0021] (1) Add 84Kg of potassium iodide to 100L of water, stir to dissolve, add 600ml of sulfuric acid, add 234L of 30% hydrogen peroxide dropwise, control the reaction temperature at 60°C, and add dropwise until the resulting yellow solution fades to colorless;

[0022] (2) Stir the reaction for 1 hour, adjust the pH of the reaction solution to 7.5 with 40% potassium hydroxide solution, raise the temperature to 90-100°C, continue to keep warm and stir the reaction until the total volume is about 120L, stop heating, and cool the reaction solution Centrifuge and dry the crystals to room temperature to obtain crude potassium iodate. The mother liquor is concentrated at 90-100°C to a small amount of crystallization, then cooled and crystallized, and the solid is incorporated into the crude potassium iodate.

[0023] (3) Add 87Kg of the obtained potassium iodate crude product to the temperature and dissolve it, adjust the specific gravity of the solution to d=1.18, heat it at 90°C ...

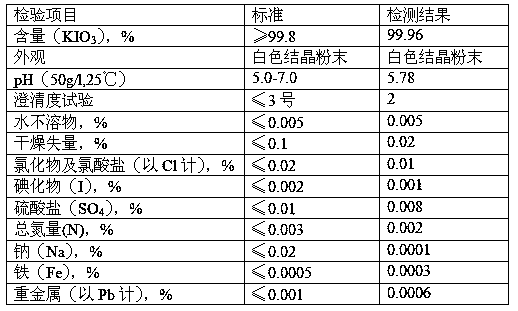

Embodiment 3

[0028] (1) Add 840g of potassium iodide to 1000ml of water, stir to dissolve, add 6ml of sulfuric acid, dropwise add 1650ml of 30% hydrogen peroxide, control the reaction temperature at 55°C, and add dropwise until the resulting yellow solution fades to colorless;

[0029] (2) Stir the reaction for 1 hour, adjust the pH of the reaction solution to 7.5 with 40% potassium hydroxide solution, raise the temperature to 90~100°C, continue to keep warm and stir the reaction until the total volume is about 1200ml, stop heating, and cool the reaction solution Centrifuge and dry the crystals to room temperature to obtain crude potassium iodate. The mother liquor is concentrated at 90-100°C to a small amount of crystallization, then cooled and crystallized, and the solid is incorporated into the crude potassium iodate.

[0030] (3) Add 998g of the obtained potassium iodate crude product to the temperature and dissolve it, adjust the specific gravity of the solution to d=1.19, keep it warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com