Comprehensive process method for salt production by seawater desalination

A technology of comprehensive process and process method, applied in the field of seawater treatment, can solve the problems of limited application range, low output rate, polluted surface water and groundwater, etc., and achieve the effect of saving land resources, improving utilization efficiency, and reducing the area of tanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

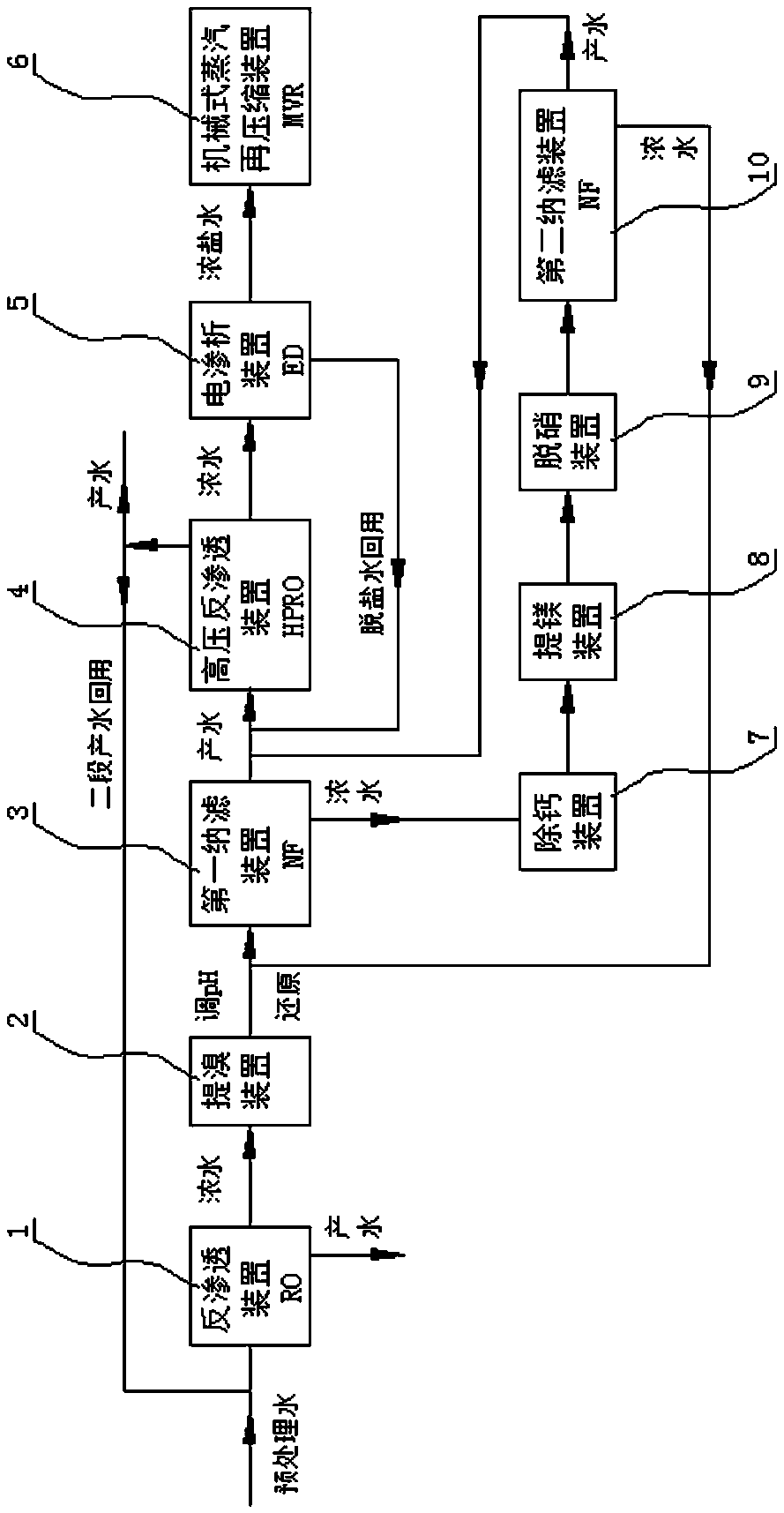

Image

Examples

Embodiment 1

[0052] A seawater desalination plant with a reverse osmosis device has an inflow of 25,000 tons / day, an inflow concentration of 3.2°Bé, sodium ions 11g / L, calcium ions 0.4g / L, magnesium ions 1.2g / L, and sulfate ions 2.3g / L , chloride ion 18g / L, bromide ion 0.065g / L, after pretreatment, enter the reverse osmosis device (1), the recovery rate is 40%, the water production is 10000 tons / day, and the water conductivity is 300μs·cm -1 Enter the secondary reverse osmosis to produce pure water; the volume of concentrated water is 15,000 tons / day, and the concentration of concentrated water is 4-5°Bé, of which sodium ions are 18.3g / L, calcium ions are 0.6-0.7g / L, and magnesium ions are 1.8-2.2g / L, sulfate ion 3.5~4.5g / L, chloride ion 29~31g / L, bromide ion 0.1g / L.

[0053] The concentrated seawater enters the bromine extraction device to extract bromine. The bromine concentration of the concentrated seawater is 0.1g / L, the pH value is controlled at 2.5-4, the chlorine distribution rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com