Formula preparation method of high-flame-retardant material for window screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

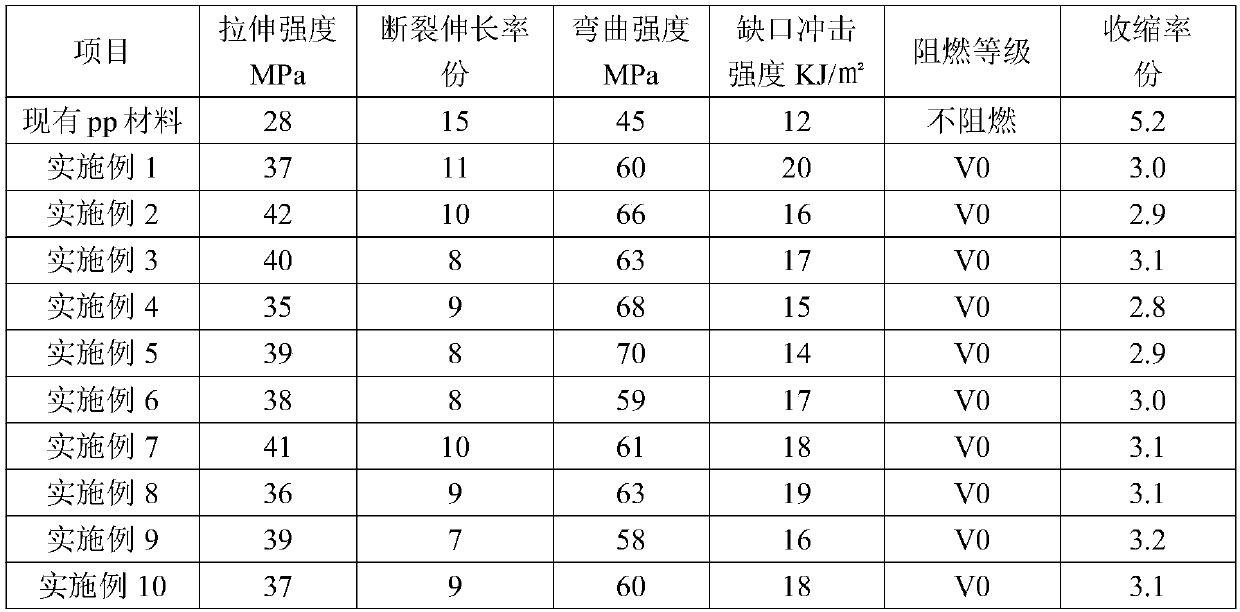

Examples

preparation example Construction

[0054] A method for preparing a highly flame-retardant material for window screens, comprising a mixing step, a filling step, and an extrusion mixing step, wherein the mixing step, the filling step, and the extrusion mixing step are performed sequentially,

[0055] In the mixing step, the flame retardant and the surfactant are uniformly mixed in a high-speed mixer and fully activated, then polypropylene, antioxidant, anti-dripping agent, and lubricant are added and mixed uniformly to obtain a mixed raw material;

[0056] In the filling step, the mixed raw materials are filled into a twin-screw extruder, and one of polyethylene and polyethylene terephthalate resin is filled into another twin-screw extruder,

[0057] In the extrusion mixing step, the materials in the two twin-screw extruders are co-extruded into the co-extrusion head, mixed in the co-extrusion head and then shaped to form a modified high flame-retardant material with a core-shell structure.

[0058] The screw sp...

Embodiment 1

[0062] Formula by mass ratio includes:

[0063] Polypropylene (PP): 70 parts

[0064] Polyethylene (PE): 10 parts

[0065] Flame retardant: 5 parts of 20nm basic aluminum carbonate; 5 parts of 50nm aluminum powder

[0066] Surfactant: 5 parts of butyl titanate

[0067] Antioxidant: 0.05 parts of trioctyl phosphite; 10100.05 parts of antioxidant

[0068] Anti-dripping agent: 3 parts

[0069] Lubricant: 1.9 parts of solid paraffin

[0070] Step 1 Mix the flame retardant and surfactant in the formula evenly in a high-speed mixer, fully activate, then add polypropylene, antioxidant, anti-dripping agent, lubricant, and mix evenly;

[0071] Step 2: Put the mixed materials in step 1 into a twin-screw extruder, and extrude them into a co-extrusion head with a special channel, the screw speed is 60rpm, and the temperature is 180°C;

[0072] Step 3 At the same time, add polyethylene to another twin-screw extruder, extrude it into the co-extrusion head of the special flow channel i...

Embodiment 2

[0074] Formula by mass ratio includes:

[0075] Polypropylene (PP): 50 parts

[0076] Polyethylene (PE): 10 parts

[0077] Flame retardant: 5 parts of 60nm magnesium hydroxide; 10 parts of red phosphorus; 15 parts of 20nm aluminum powder

[0078] Surfactant: 7 parts of aluminate

[0079] Antioxidant: 0.15 parts of triethyl phosphite; 0.05 parts of Irganox B9000

[0080] Anti-dripping agent: 2 parts

[0081] Lubricant: 0.8 parts of microcrystalline paraffin

[0082] Step 1 Mix the flame retardant and surfactant in the formula evenly in a high-speed mixer, fully activate, then add polypropylene, antioxidant, anti-dripping agent, lubricant, and mix evenly;

[0083] Step 2: Put the mixed materials in step 1 into a twin-screw extruder, and extrude them into a co-extrusion head with a special channel, the screw speed is 60rpm, and the temperature is 180°C;

[0084] Step 3 At the same time, add polyethylene to another twin-screw extruder, extrude it into the co-extrusion head o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com