Method for producing gamma-polyglutamic acid by using Flammulina velutipes waste

A technology of polyglutamic acid and Flammulina velutipes is applied in the field of green biological materials to achieve the effects of less heat consumption, lower production cost and shorter production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

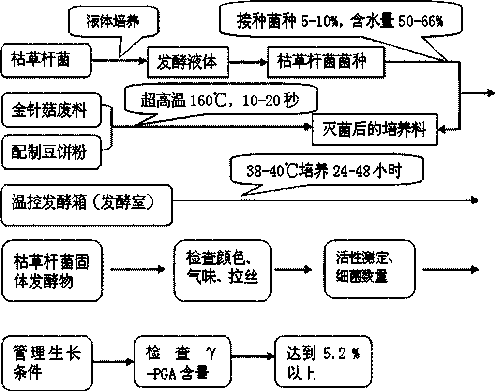

Method used

Image

Examples

Embodiment 1

[0024] The main material of the waste culture medium is Flammulina velutipes mycelium, and 90 kg of remaining culture components composed of cottonseed hulls, bran, corn cobs, bean cakes, and sawdust. After adding 12 kg of bean cake powder, it is sterilized by a known sterilization method. Spread flat in the fermentation tray,

[0025] The inoculation temperature is 20-85℃, and the best condition is 80-85℃; the inoculation of bioengineering bacteria-Bacillus subtilis, the inoculation amount is 10 kg, mixed with 140 kg of sterilized water before use. Therefore, the specific method is: add 500 grams to each fermentation tray, spray 750 ml evenly, and inoculate a mixture of bacteria and sterilized water. Fermentation pallet truck 12 trays / unit, double door 24 trays, each fermentation box contains 12 kg of raw materials and enters the management. The fermentation temperature is 38-40°C, and the solid fermentation time of Bacillus subtilis is 24-48 hours. According to the inspection...

Embodiment 2

[0028] The main material of the waste culture medium is Flammulina velutipes mycelium, as well as 180 kg of remaining culture components composed of cottonseed hulls, bran, corn cob, bean cake, and sawdust. After adding 25 kg of bean cake powder, it is sterilized by known sterilization methods. Spread flat in the fermentation tray,

[0029] The inoculation temperature is 20-85℃, and the best condition is 80-85℃; the inoculation of bioengineering bacteria-Bacillus subtilis, the inoculation amount is 20 kg, mixed with 280 kg of sterilized water before use. Therefore, the specific method is: add 500 grams to each fermentation plate, spray 750 milliliters evenly, and inoculate a mixture of bacteria and sterilized water. Fermentation pallet truck 12 trays / unit, double door 24 trays, each fermentation box contains 12 kg of raw materials and enters the management. The fermentation temperature is 38-40°C, and the solid fermentation time of Bacillus subtilis is 40 hours. According to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com