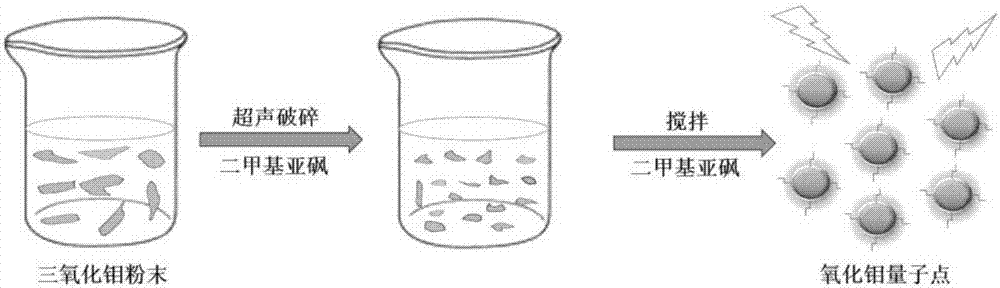

Preparation method of molybdenum oxide quantum dot by one-step method

A technology of molybdenum oxide and quantum dots, which is applied in molybdenum oxide/molybdenum hydroxide, measuring devices, nanotechnology for materials and surface science, etc., to achieve uniform size, strong fluorescent performance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] S1. Weigh 1 g of molybdenum trioxide in 100 mL of dimethyl sulfoxide, and then stir to obtain a milky white suspension solution for later use;

[0021] S2. Ultrasonicate the milky white suspension solution prepared in S1 with a power of 300 watts for 3 hours;

[0022] S3, adding a rotor to the ultrasonicated solution in S2, and stirring the solution on a magnetic stirrer at a speed of 260 rpm for 12 hours;

[0023] S4. Take the stirred solution in S3 and put it into a centrifuge tube, centrifuge at a speed of 12,000 rpm for 10 minutes, and take the supernatant after solid-liquid separation, which is the molybdenum oxide quantum dot solution.

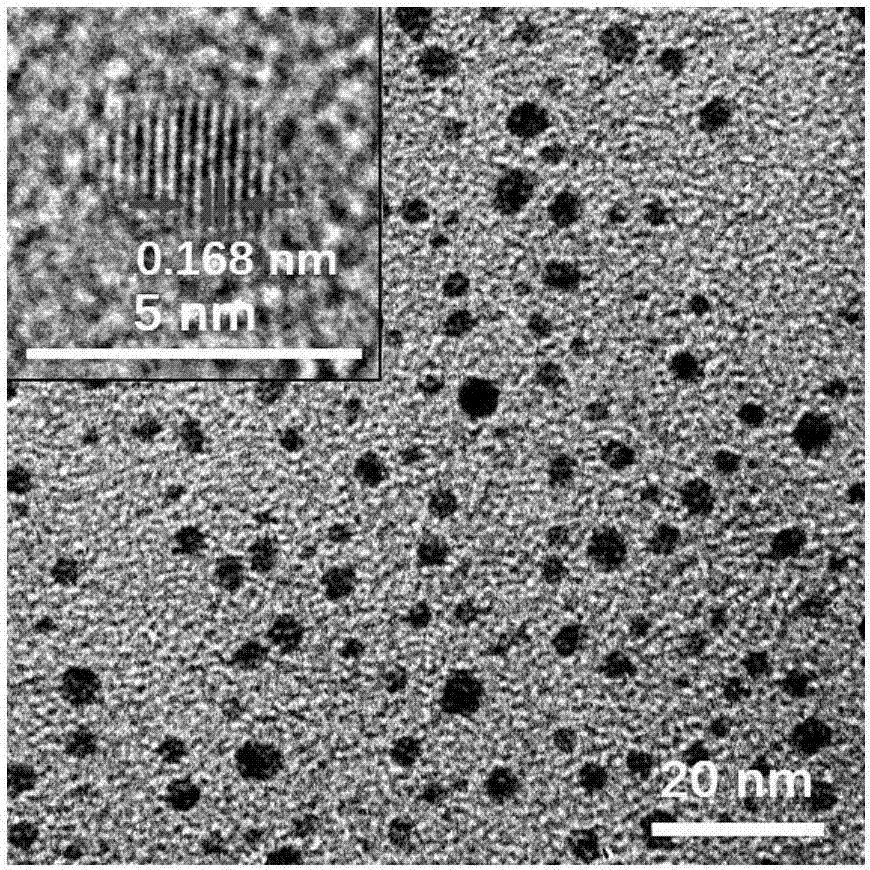

[0024] The molybdenum oxide quantum dot solution prepared in this example is measured, the quantum dot particles prepared in this example are uniform and less than 8nm, the average size is 3.25nm, and the quantum yield is 3.85%, which proves that the present invention can reliably and stably prepare molybdenum oxide quantum dots ...

Embodiment 2

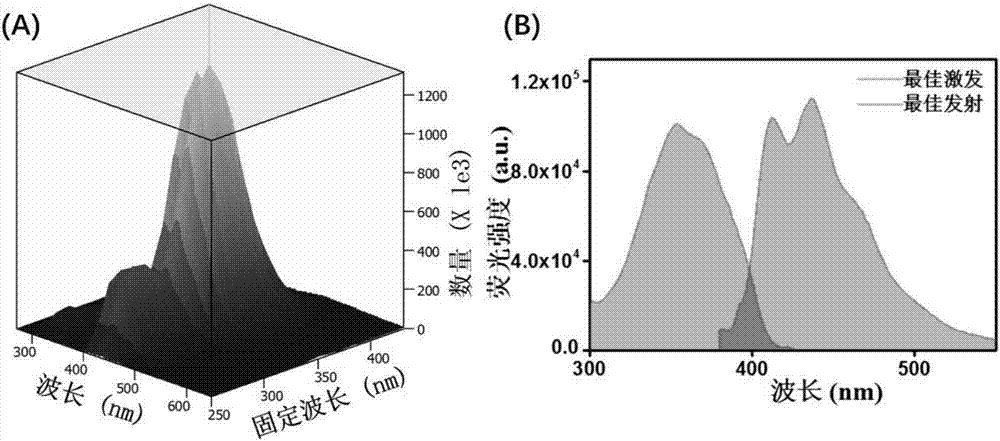

[0026] In this embodiment, the molybdenum oxide quantum dots prepared in Example 1 have been tested for fluorescence properties, as image 3 (B) shows that the maximum excitation wavelength is located at 436 nm in the case of the optimal excitation wavelength of 350 nm.

Embodiment 3

[0028] The molybdenum oxide quantum dots prepared in Example 1 can be specifically quenched by ferric iron, so the prepared molybdenum oxide quantum dots can be applied to the specific and sensitive detection of ferric iron and pyrophosphate anion content, The result is as Figure 4 As shown, when the concentration of ferric ions increases from 0 to 1400 micromole per liter, the corresponding fluorescence intensity is as Figure 4 As shown in (A); when the concentration of ferric iron is in the range of 100 to 260 micromole per liter, the fluorescence intensity and ferric iron present a linear relationship, such as Figure 4 Shown in (B); Continue to add sodium pyrophosphate solution in solution afterwards, fluorescence intensity record is as follows Figure 4 As shown in (C), when the pyrophosphate ion concentration is between 0 and 60 micromole per liter, the fluorescence intensity has a good linear relationship with the pyrophosphate ion concentration, as shown in 4 (D); t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com