Microporous high-alumina bauxite clinker lightweight refractory brick and preparation method thereof

A high-alumina bauxite clinker and refractory brick technology, which is applied in the field of refractory materials, can solve the problems of increased thermal conductivity of refractory materials, increased heat energy loss, and aggravation, so as to achieve a firm skeleton structure, increase the critical particle size, and ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

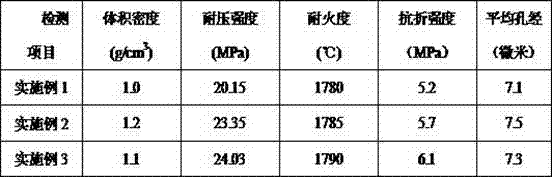

Embodiment 1

[0029] This embodiment provides a microporous high-alumina bauxite clinker lightweight refractory brick, including main ingredients and pulp water, wherein the main ingredients include the following materials in mass percentages: 30% of high-alumina bauxite clinker large particles, Calcium aluminate fine powder 25%, kaolin superfine powder 8%, Al 2 o 3 Micropowder 15%, silicon micropowder 8%, starch 12%, fine silica airgel 2%; the quality of the pulp water is 5.5% of the mass of the main material. The particle size of the large particles of high alumina bauxite clinker is 1 mm to 3 mm, the particle size of the calcium aluminate fine powder is less than 0.074 mm, the particle size of the combined clay fine powder is less than 0.074 mm, the Al 2 o 3 The particle size of the micropowder is less than 0.043 mm, and the particle size of the silicon micropowder is less than 0.043 mm. The chemical composition of each raw material is shown in Table 1.

[0030] Table 1, the main ch...

Embodiment 2

[0036] This embodiment provides a microporous high-alumina bauxite clinker lightweight refractory brick, including main ingredients and pulp water, wherein the main ingredients include the following materials in mass percentages: 30% of high-alumina bauxite clinker large particles, Calcium aluminate fine powder 20%, kaolin superfine powder 10%, Al 2 o 3 Micropowder 20%, silicon micropowder 7%, nano-carbon black 10%, fine silica airgel 3%; the quality of the pulp water is 5.5% of the mass of the main material.

[0037] The preparation method of the microporous high-alumina bauxite clinker lightweight refractory brick described in this embodiment is roughly the same as the preparation method in Example 1, except that:

[0038] The mixed and milled mud is pressed into adobe, then placed in a drying kiln, and dried at a temperature of 200°C for 48 hours; then the dried adobe is calcined at a temperature of 1100°C for 24 hours to produce The microporous high-alumina bauxite clink...

Embodiment 3

[0041] This example provides a light-weight refractory brick made of microporous high-alumina bauxite clinker. The specific raw material composition is roughly the same as that of Example 1, except that:

[0042] In this example, high alumina bauxite clinker large particles 18%, calcium aluminate fine powder 25%, kaolin superfine powder 12%, Al 2 o 3 Micro powder 25%, silicon micro powder 5%, petroleum coke 12%, fine silica airgel 3%.

[0043] The preparation method of the microporous high-alumina bauxite clinker lightweight refractory brick described in this example is the same as that in Example 1. After testing, the density of the microporous high-alumina bauxite clinker lightweight refractory bricks prepared in this example is 1.1 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com