Silicon dioxide/magnesium oxide/polymer dielectric and hydrophobic composite material and preparation method

A technology of hydrophobic material, silica, applied in the field of nanocomposite materials, can solve the problems of limited application, insufficient dielectric properties and hydrophobic properties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

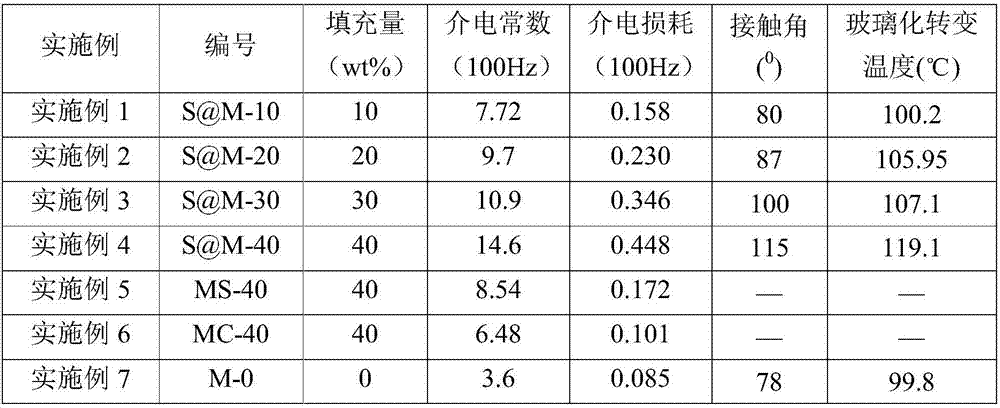

Embodiment 1-4

[0034] (1) Add 60ml of deionized water, 4g of magnesium chloride hexahydrate, and 1g of polyvinylpyrrolidone into a 100ml stainless steel reactor with a polytetrafluoroethylene liner, stir the solution at room temperature until it becomes clear, then add 3ml of ammonia water dropwise, and stir Seal it after 5 minutes, move it into a blast drying oven and keep it warm at 180°C for 3 hours.

[0035] (2) After the reaction, cool naturally to room temperature; centrifuge to obtain a white precipitate, alternately wash several times with deionized water and ethanol, move to a drying oven at 60° C. and dry for 24 hours to obtain the precursor magnesium hydroxide.

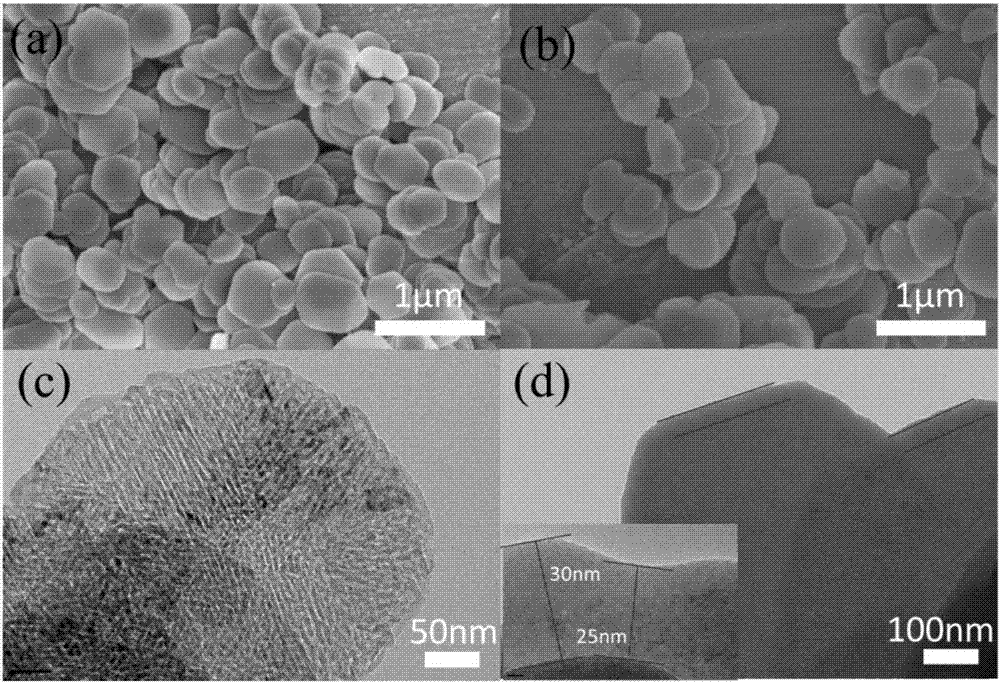

[0036] (3) Burn the precursor magnesium hydroxide in the air for 3 hours at a temperature of 500°C to obtain white magnesium oxide powder (its microscopic shape is flake, such as figure 1 ).

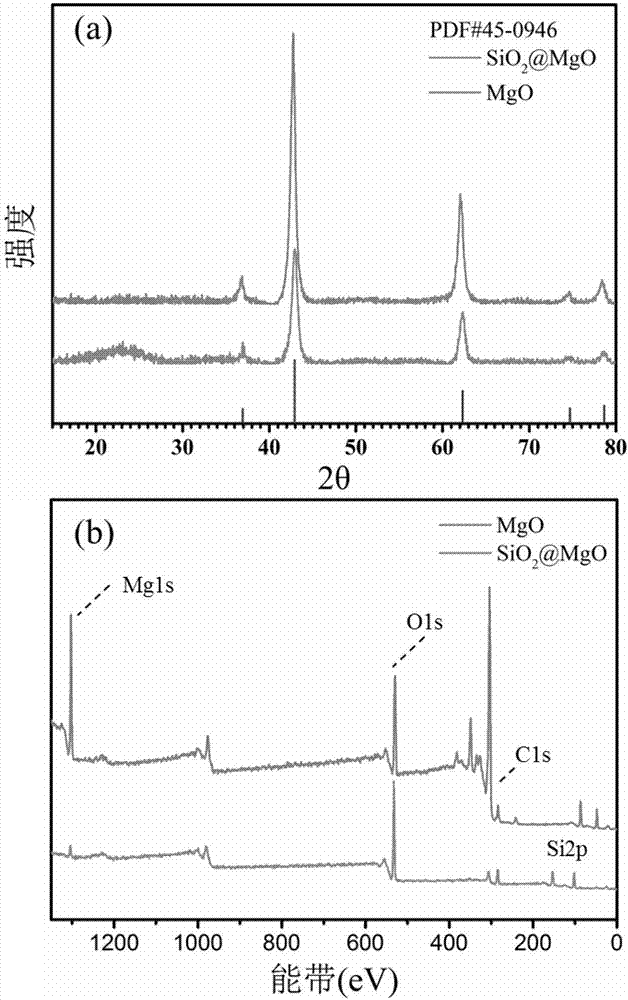

[0037] (4) Take 1 g of the flaky magnesium oxide prepared in step (3), and ultrasonically disperse it in 60 ml of ethanol. Add 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com