Method for rapidly preparing high-purity sodium thiosulfate crystals

A pure sodium thiosulfate and sodium sulfite technology, applied in the direction of thiosulfate/dithionite/polythionite, etc., can solve the problems of slow crystal precipitation, long experiment time, and time-consuming concentration, and achieve crystal The precipitation speed is fast, the experimental equipment is less, and the effect of reducing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

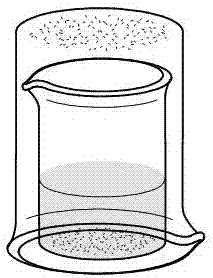

Image

Examples

Embodiment Construction

[0010] The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0011] Put 6.3 g of sodium sulfite, 3.2 g of sulfur powder, and 30 mL of distilled water into a small beaker, close the large beaker, heat the reaction in microwave for 1 min, cool to room temperature, and recover the sulfur powder by suction filtration; add 150 mL of acetone to the filtrate, stir for 5~ Crystals appeared in 6 minutes, filtered by suction, washed with 10 mL of acetone to obtain sodium thiosulfate crystals, dried in vacuum for 2 hours, and weighed; acetone was recovered from the filtrate by distillation and reused; the remaining liquid was recovered for use in preparation again.

[0012] The optimal condition of the heating reaction is: heating at 210 W for 3*20 s;

[0013] The optimum mass ratio of the reaction raw materials is sodium sulfite: sulfur powder: distilled water=6.3:3.2:30, and the filtrate is best treated with 150 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com