A kind of C3 selective hydrogenation catalyst, preparation method and hydrogenation method

A technology for selective hydrogenation and catalysts, which is applied in the fields of hydrogenation to hydrocarbons, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Cumbersome and other problems, to achieve the effect of good organic sulfur adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

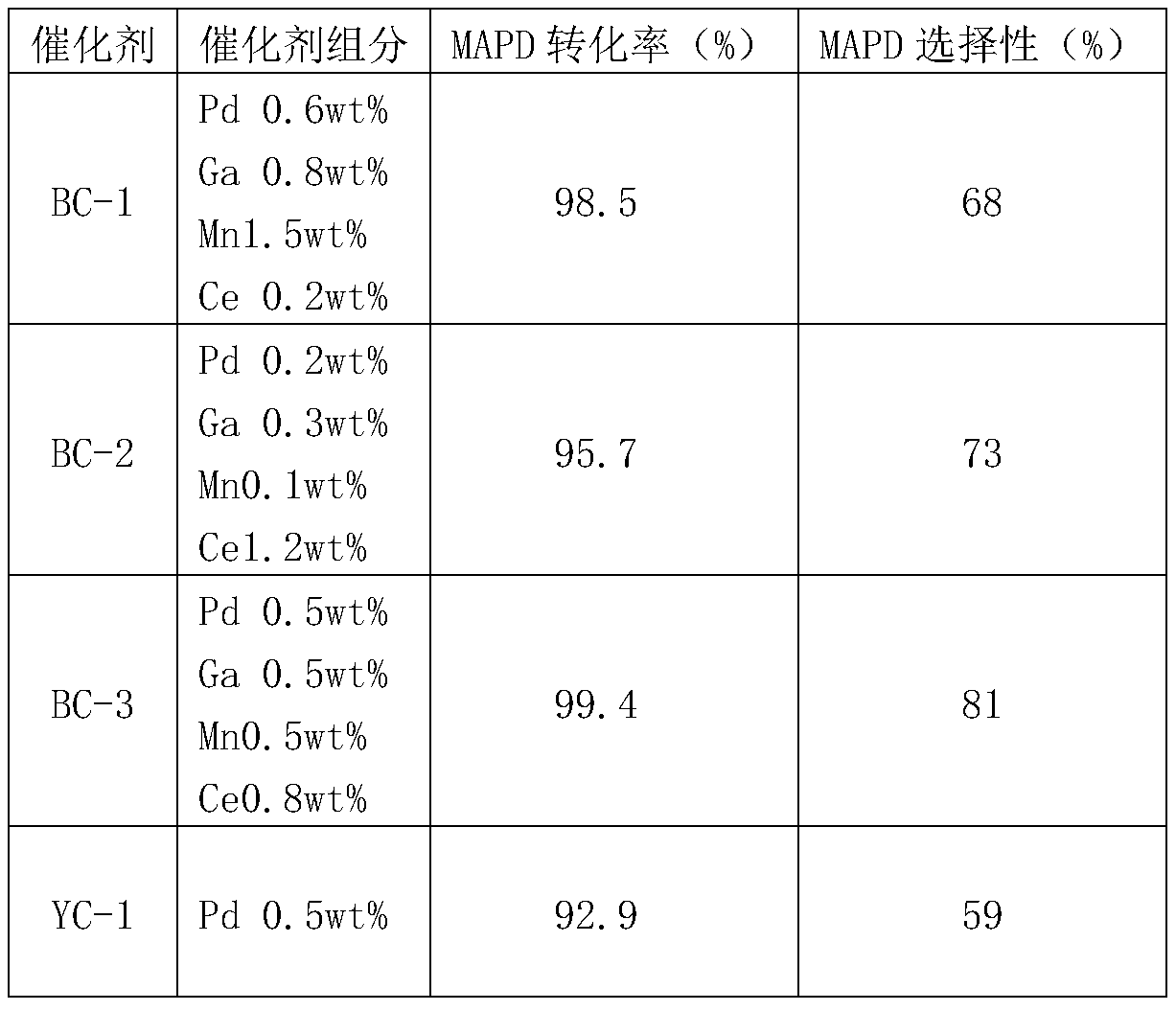

Embodiment 1

[0066] ① Preparation of MnCl containing 1.5gMn 2 and 0.2gCe of CeCl 3 45ml of ethanol solution, 100g of toothed spherical carrier Al 2 o 3 Immersed in the solution, dried at 95°C, and calcined at 1115°C to obtain Mn and Ce modified carrier Al 2 o 3 ;

[0067] ② Preparation of Pd(NO 3 ) 2 65ml of aqueous solution, the carrier Al modified by Mn and Ce 2 o 3 Immerse in the solution, dry at 105°C, and bake at 500°C to obtain Pd / Al 2 o 3 catalyst;

[0068] ③ Preparation of Ga(NO) containing 0.6gGa 3 ) 3 65ml of aqueous solution, the solution is sprayed on Pd / Al 2 o 3 On the catalyst, dry at 110°C and bake at 410°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0069] ④In a fixed-bed reactor, use a mixed gas of methane and hydrogen containing 90% hydrogen to reduce at 330°C for 12 hours, and the temperature control range is ±2°C to obtain catalyst BC-1, wherein the Pd content is 0.6wt%, Ga The content of Mn is 0.8wt%, that of Mn is 1.5wt%, and that of Ce is 0.2wt%. ...

Embodiment 2

[0071] ①Prepare 50ml of aqueous solution of manganese acetate containing 0.1gMn and cerium acetate of 1.2gCe, and 100g spherical carrier Al 2 o 3 Immersed in the solution, dried at 110°C, and calcined at 980°C to obtain Mn and Ce modified carrier Al 2 o 3 ;

[0072] ② Preparation of PdCl containing 0.2gPd 2 52ml of aqueous solution, the carrier Al modified by Mn and Ce 2 o 3 Immerse in the solution, dry at 105°C, and bake at 400°C to obtain Pd / Al 2 o 3 catalyst;

[0073] ③ Preparation of GaCl containing 0.3gGa 3 55ml of n-butanol solution, the solution is impregnated in Pd / Al 2 o 3 On the catalyst, dry at 125°C and bake at 320°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0074]④In a fixed-bed reactor, use a mixed gas of nitrogen and hydrogen containing 85% hydrogen to reduce at 265°C for 10 hours, and the temperature control range is ±1°C to obtain catalyst BC-2, wherein the Pd content is 0.2wt%, Ga The content of Mn is 0.3wt%, that of Mn is 0.1wt%, and that o...

Embodiment 3

[0076] ① Preparation of Mn(NO 3 ) 2 and 0.8gCe of Ce(NO 3 ) 2 58ml of aqueous solution, 100g column carrier Al 2 o 3 Immersed in the solution, dried at 120°C, and calcined at 1090°C to obtain Mn and Ce modified carrier Al 2 o 3 ;

[0077] ② Preparation of PdCl containing 0.5gPd 2 45ml of ethanol solution, the Mn and Ce modified carrier Al 2 o 3 Immerse in the solution, dry at 105°C, and bake at 450°C to obtain Pd / Al 2 o 3 catalyst;

[0078] ③ Prepare 58ml of an aqueous solution of gallium trifluoromethanesulfonate containing 0.3gGa, and impregnate the solution in Pd / Al 2 o 3 On the catalyst, dry at 110°C and bake at 360°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0079] ④In a fixed-bed reactor, use a mixed gas of nitrogen and hydrogen containing 80% hydrogen to reduce at 310°C for 8 hours, and the temperature control range is ±1°C to obtain catalyst BC-3, wherein the Pd content is 0.5wt%, Ga The content of Mn is 0.3wt%, that of Mn is 0.5wt%, and that of Ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com