A mesoporous-rich molecular sieve and preparation method thereof

A molecular sieve, mesoporous technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as low micropore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

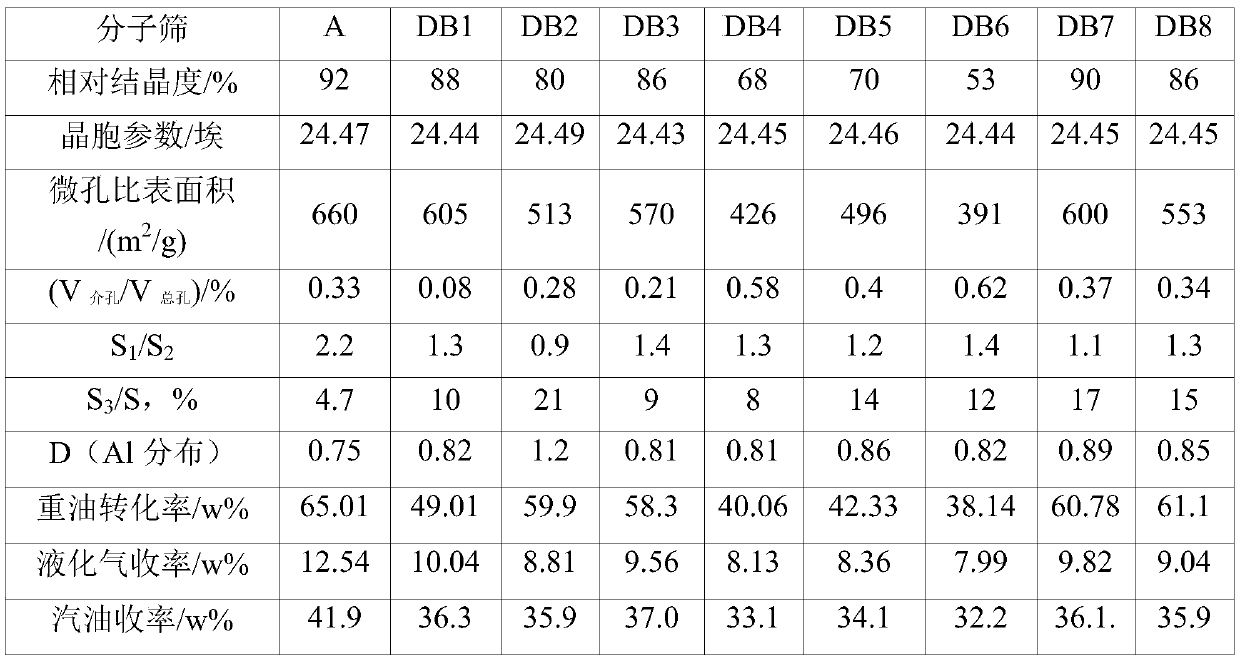

Examples

preparation example Construction

[0030] The present disclosure also provides a preparation method of the mesoporous-rich Y molecular sieve provided in the present disclosure, the preparation method comprising: a. performing ammonium exchange treatment on the NaY molecular sieve, followed by filtration and washing to obtain the ammonium exchange molecular sieve; Wherein, based on sodium oxide and based on the dry weight of the ammonium exchanged molecular sieve, the sodium oxide content of the ammonium exchanged molecular sieve is less than 5% by weight; b, roasting the ammonium exchanged molecular sieve obtained in step a to obtain roasted Molecular sieve; c, the roasted molecular sieve obtained in step b is subjected to dealumination and silicon supplementation treatment under anhydrous conditions using silicon tetrachloride gas to obtain a dealumination silicon supplementation molecular sieve; d, the dealumination silicon supplementation molecular sieve obtained in step c is processed by Carry out the first ...

Embodiment 1

[0052] Y molecular sieve (produced by Catalyst Qilu Branch, unit cell parameter 24.63 angstroms) and NH 4 Cl and distilled water were mixed and beaten evenly at a ratio of 1:1:10, ammonium was exchanged at 70°C for 1 hour, the sample was filtered, washed, and dried, and the sodium oxide content of the molecular sieve was measured to be less than 5% by weight. The obtained molecular sieves were calcined at 600° C. for 2 h. Take the calcined molecular sieve in an anhydrous dry environment, pass through SiCl 4 Saturated dry gas, the reaction temperature is 550°C, and the reaction time is 2h; take 100g (dry basis mass) of the obtained molecular sieve and add water to prepare a molecular sieve slurry with a solid content of 10% by weight, add 3g of citric acid during stirring, and then add 400g of hydrochloric acid (mass fraction 10%), the addition time was 30min; the temperature was raised to 75°C and stirred for 1h, filtered and washed until the filtrate was neutral; the sample ...

Embodiment 2

[0070] Y molecular sieve (produced by Catalyst Qilu Branch, unit cell parameter 24.63 angstroms) and NH 4 Cl and distilled water were mixed and beaten evenly at a ratio of 1:1:10, ammonium was exchanged at 70°C for 1 hour, the sample was filtered, washed, and dried, and the sodium oxide content of the molecular sieve was measured to be less than 5% by weight. The obtained molecular sieves were calcined at 550° C. for 3 h. Take the calcined molecular sieve in an anhydrous dry environment, pass through SiCl 4 Saturated dry gas, the reaction temperature is 550°C, and the reaction time is 2h; take 100g (dry basis mass) of the obtained molecular sieve and add water to prepare a molecular sieve slurry with a solid content of 10% by weight, add 5g of oxalic acid during stirring, and then add 200g of sulfuric acid (mass fraction 10% by weight) %), the addition time is 30 minutes; the temperature is raised to 30° C. and stirred at a constant temperature for 2 hours, filtered and washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com