Cellulose/two-dimensional layered material composite hydrogel and preparation method thereof

A composite hydrogel and two-dimensional layered technology, which is applied in the field of cellulose/two-dimensional layered material composite hydrogel and its preparation, can solve the problem of restricting the development of cellulose, difficult processing and molding, and insoluble and infusible cellulose and other issues, to achieve good mechanical strength, complete biocompatibility, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

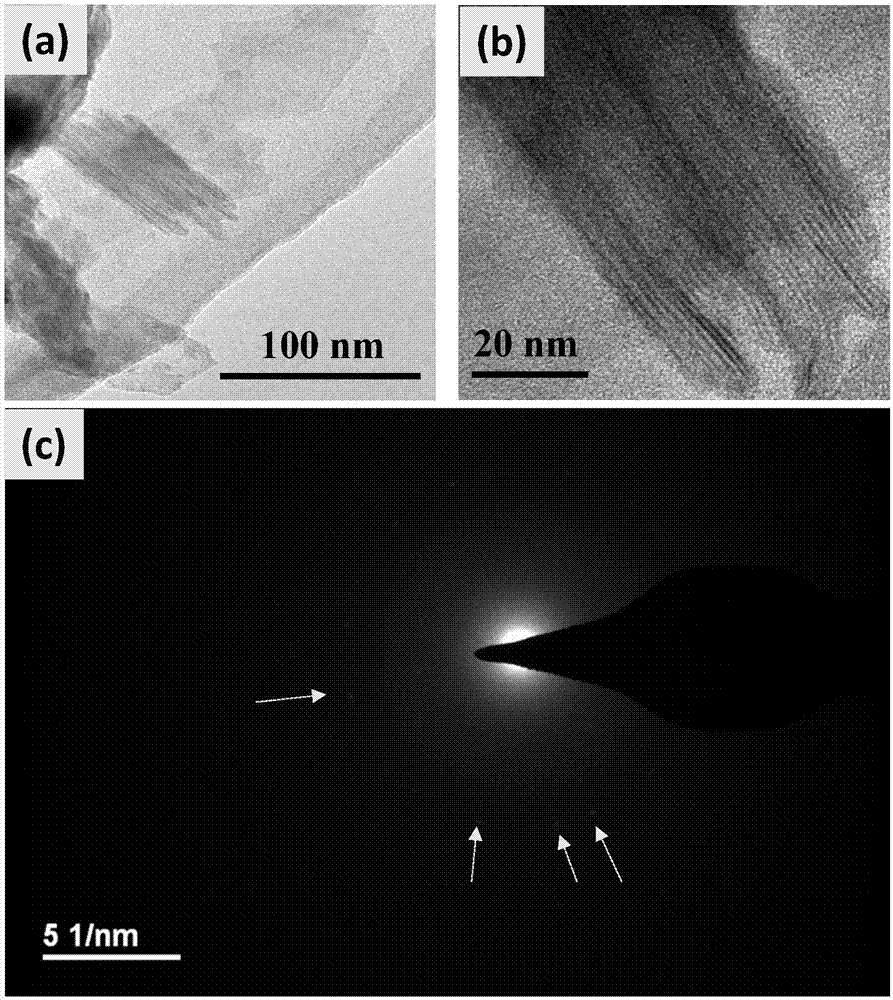

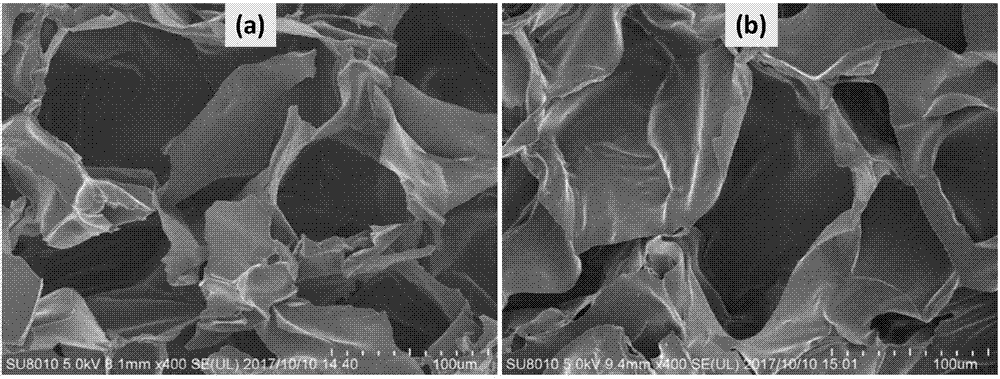

[0075] A kind of cellulose / few layer Ti 3 C 2 T x A method for preparing a composite hydrogel of nanosheets, comprising:

[0076] Step (1). Preparation of few-layer Ti by liquid phase exfoliation 3 C 2 T x Nanosheet, its specific steps are as follows:

[0077] 1-a): Preparation of multilayer Ti by hydrofluoric acid etching 3 C 2 T x Material, the specific operation of the material is as follows: the powdery ternary layered nitride Ti 3 AlC 2 Add hydrofluoric acid aqueous solution (the mass fraction of HF is 10% to 40%) into a polyethylene plastic beaker to react according to the solid content ratio of 10g / 100mL. Among them, the ternary layered nitride Ti 3 C 2 T x It needs to be slowly added into the hydrofluoric acid aqueous solution, and the time for slow addition is 10 minutes to 30 minutes. After the addition is completed, react at the reaction temperature for 12 hours to 24 hours. After the reaction, the obtained etching mixture was centrifuged at 17000 rpm ...

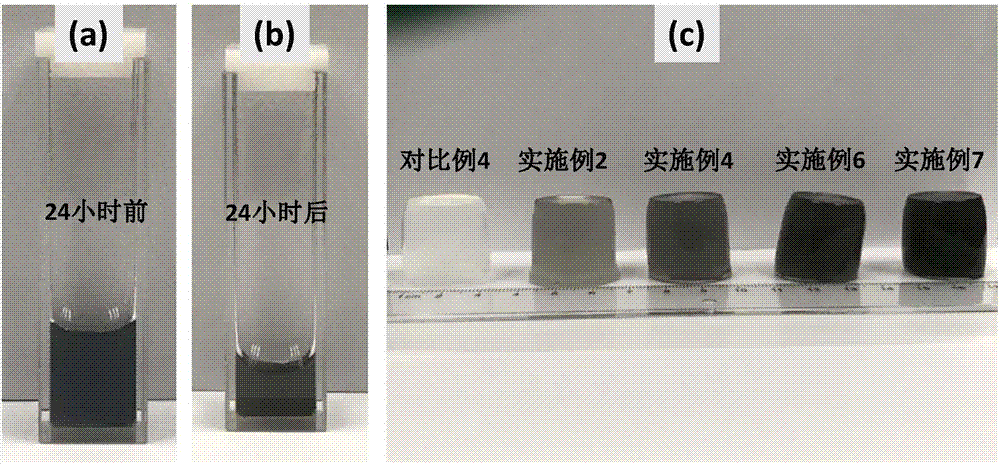

Embodiment 2

[0092] Preparation of cellulose / few-layer Ti 3 C 2 T x The composite hydrogel of nanosheet / , the difference with embodiment 1 is, in step 3-a), cellulose and few layers of Ti 3 C 2 T x The mass ratio of nanosheets is 100:0.01.

Embodiment 3

[0094] Preparation of cellulose / few-layer Ti 3 C 2 T x The composite hydrogel of nanosheet / , the difference with embodiment 1 is, in step 3-a), cellulose and few layers of Ti 3 C 2 T x The mass ratio of nanosheets is 100:0.03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com