A catalytic cracking method for producing light olefins and light aromatics

A technology for catalytic cracking and low-carbon olefins, applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, petroleum industry, etc., can solve the problems of increased and limited yield of light aromatics, and achieve reduced selectivity, high BTX yield, improved The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The present invention also provides a method of preparing the catalytic cleavage catalyst, comprising preparing the phosphorus-containing and negative metal IMF structural molecular sieve, which will be sieved and a molecular sieve, natural mineral, natural mineral, natural mineral , The oxide pre-body sol is mixed, spray drying; wherein the preparation method of the phosphorus-containing and load metal IMF structural molecular sieve includes:

[0073] A. The sodium IMF structure molecular sieve is subjected to a silicon sketch; B is obtained, and the dexuxiliary molecular sieve obtained in step A is used to obtain a ammonium exchange molecular sieve; wherein the sodium oxide is measured. The total dry base weight of the ammonium exchange molecular sieve is based. The sodium content of the ammonium exchange molecular sieve is less than 0.2% by weight; C, the ammonium exchange molecular sieve obtained in step B is subjected to complexate composed of fluorosilic acid, organic...

Embodiment

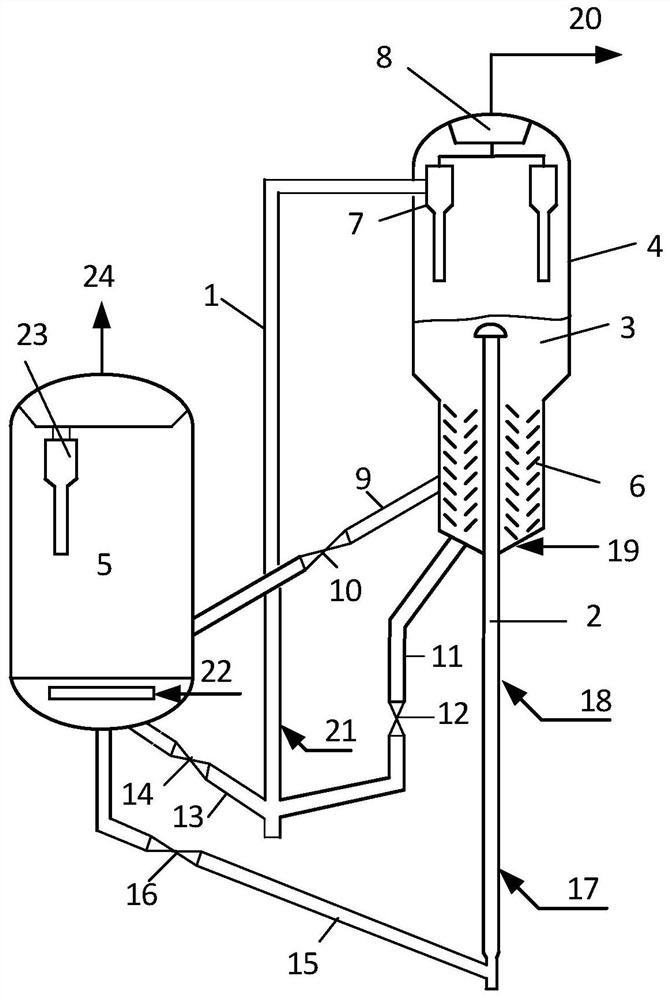

[0122] according to figure 1 The test process, the feedstock is a vacuum gas oil, catalytic cracking catalyst prepared in the preceding, on a pilot plant test, three reactors are operating pressure hydrocracking tail oil into the riser 1, in a reaction temperature 580 ℃, the reaction time of 2.0 seconds, a mixture of regenerated catalyst and spent catalyst (spent catalyst wherein the catalyst mixture accounted for 20 wt%) by weight of the feedstock oil ratio 10, the weight ratio of steam to oil feed is carried out under conditions of 0.25 cleavage reaction, the reaction of oil and gas and water vapor into the cyclone and the spent catalyst from the reactor outlet.

[0123] Aromatic raffinate oil (saturated hydrocarbon content of 87 wt%) into the riser bottom 2, at a reaction temperature of 625 deg.] C, the reaction time is 1.8 seconds, regenerated catalyst to feed oil weight ratio of 15, the weight ratio of steam to oil feed is 0.25 carried out under the conditions of the cleavage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com