Sodium alginate and calcium ion modified charcoal composite material as well as preparation method and application thereof

A technology of sodium alginate and composite materials, which is applied in chemical instruments and methods, water pollutants, other chemical processes, etc., to achieve the effects of short production cycle, simple preparation process and operation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

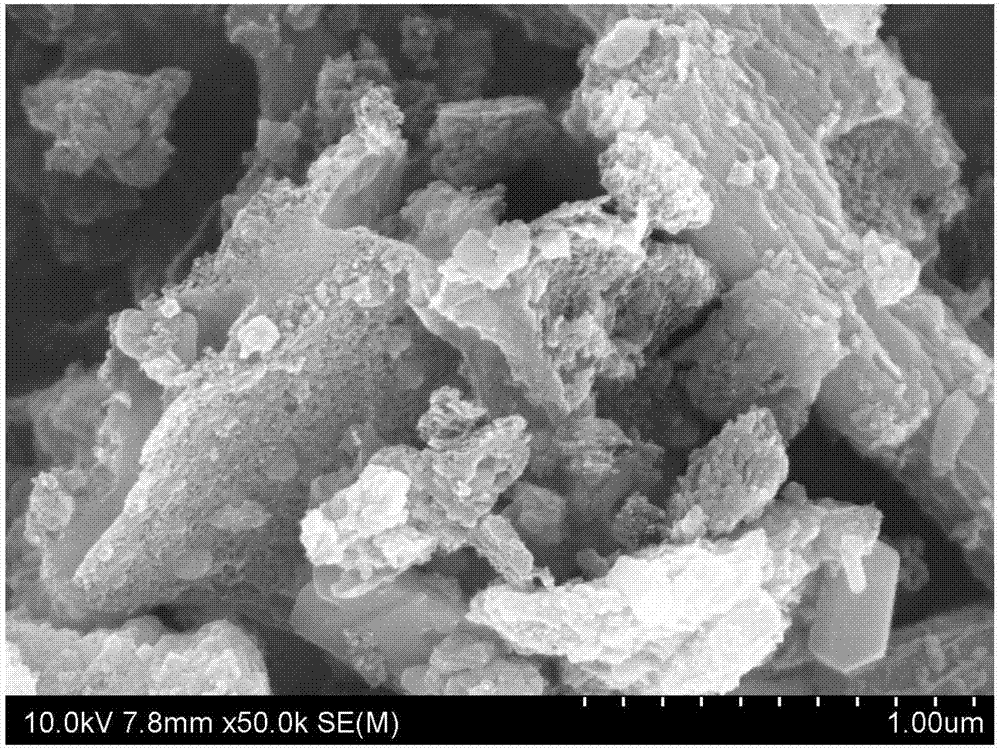

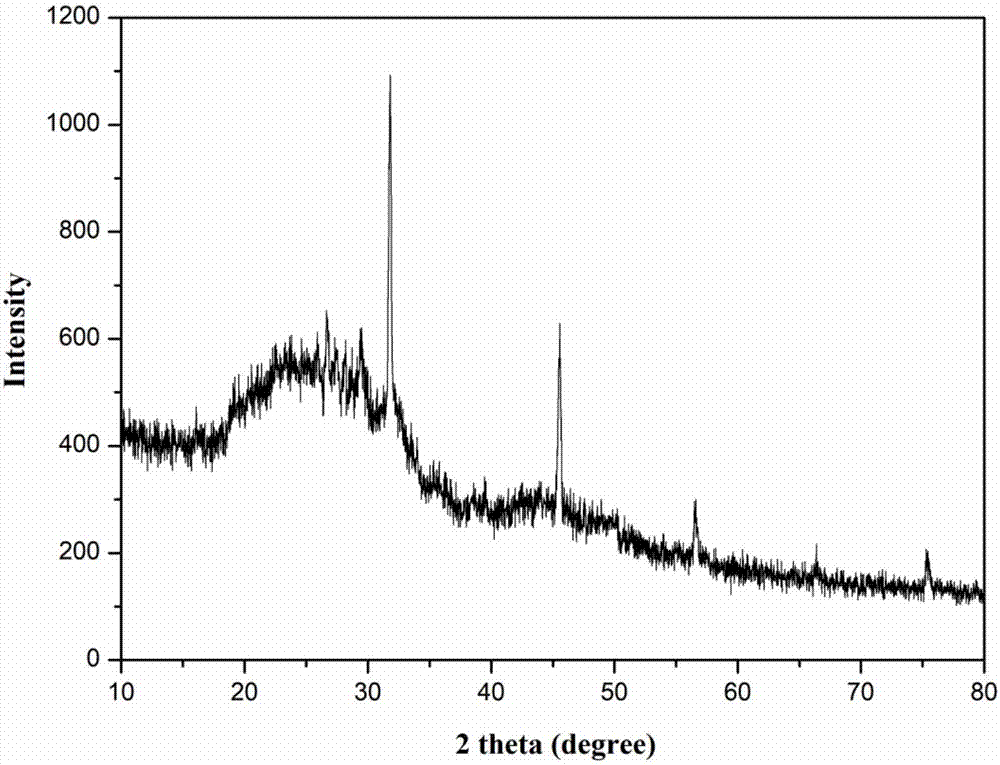

[0025] A kind of preparation of sodium alginate-calcium ion modified biochar composite material of the present invention, biochar raw material selects rice straw, and specific preparation method is as follows:

[0026] The biomass raw material was washed with deionized water, then dried at 70°C for 24 hours, the dried biomass was pulverized, and passed through a 2mm sieve to obtain biomass powder; 15.0g of CaCl 2 2H 2 O was added to 200mL of ultrapure water, and then 10.0g of biomass powder was added to the solution, and the mixed suspension was shaken in a shaking box at a speed of 150 rpm for 24 hours to obtain a biomass suspension; After the suspension was filtered, the filter residue was placed in an oven, and dried at 80°C for 24 hours to obtain a dry biomass powder loaded with calcium ions; the obtained dry biomass powder loaded with calcium ions was pyrolyzed and fired in a tubular atmosphere furnace, During the solution process, the quartz tube of the atmosphere furna...

Embodiment 2

[0029] The sodium alginate-calcium ion modified biochar composite material of the present invention treats the lead ion in the waste water, comprises the following steps:

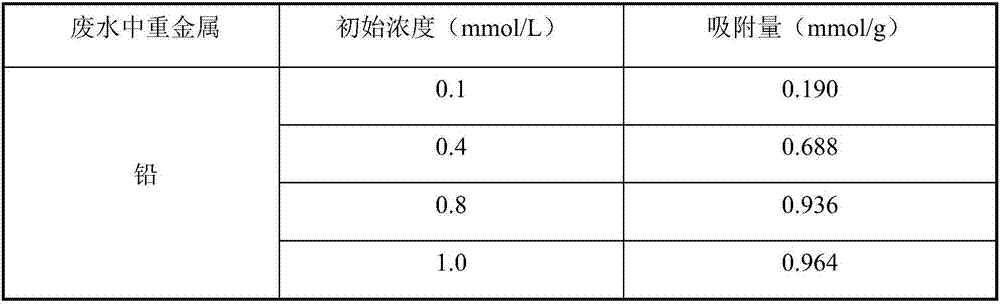

[0030] Take 50mL of the heavy metal solution with an initial concentration of 0.5-2mmol / L, add the sodium alginate-calcium ion modified biochar composite material prepared in Example 1, the amount of the adsorbent is 0.025g, and the Carry out oscillating adsorption reaction, separate this adsorbent from waste water by filtration after 24 hours, measure the content of unadsorbed lead ions in waste water with atomic absorption instrument, the adsorption amount result of calculation is as shown in table 1:

[0031] Table 1: Adsorption capacity data of adsorbents under different initial concentrations of lead ions

[0032]

[0033] It can be seen from Table 1 that the adsorbent has an adsorption capacity of 0.190mmol / g under the condition that the initial concentration is 0.1mmol / L, and it increases with the...

Embodiment 3

[0035] The sodium alginate-calcium ion modified biochar composite material of the present invention treats the lead ion in the waste water, comprises the following steps:

[0036] Get 50mL of the lead ion solution whose initial concentration is 0.5mmol / L, add the sodium alginate-calcium ion modified biochar composite material that embodiment 1 makes, the consumption of this adsorbent is 0.5g / L in the constant temperature cultivation of different temperature Box (25, 30, 35 ℃) for adsorption, after 24 hours, the adsorbent was separated from the wastewater by filtration, and the content of unadsorbed lead ions in the wastewater was measured with an atomic absorption instrument. The calculated adsorption results are shown in the table 2 shows:

[0037] Table 2: Adsorption data of lead ions at different temperatures

[0038] temperature(℃)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com