Submerged-arc welding overlaying technology

A technology of submerged arc welding and submerged arc automatic welding machine, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc. quality, the effect of improving the ability to resist intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

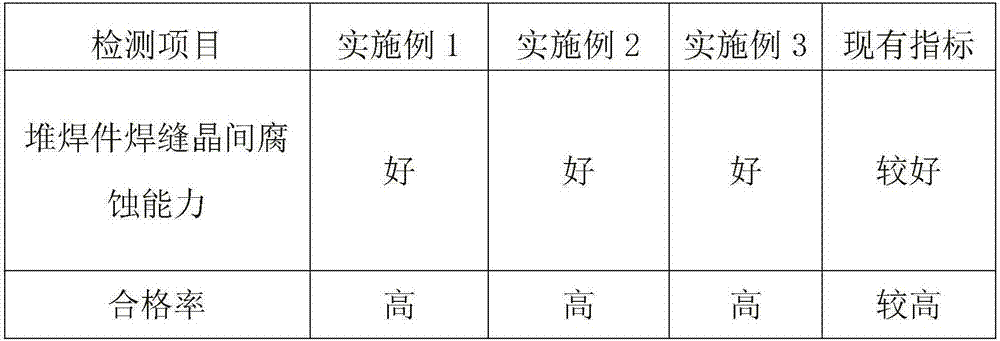

Examples

Embodiment 1

[0028] A submerged arc welding surfacing process, comprising the steps of:

[0029] (1) Overlay inspection

[0030] First check the integrity of the surfacing weldment;

[0031] (2) Pretreatment

[0032] Grind the surface of the welded overlay after inspection with an angle grinder, and then use acetone to remove scale and oil;

[0033] (3) Washing and drying with water

[0034] The surface of the pre-treated surfacing weldment is washed with water, and then the drying process is carried out. The drying temperature is 50 ° C, and the drying time is 20 minutes. The surface washing is divided into three-stage washing, and the three-stage The water washing includes first-level water washing, second-level circulating pure water washing and third-level fresh pure water washing;

[0035] (4) Preheating

[0036] Preheat the dried surfacing in the preheating chamber for 1 hour, and the temperature of the preheated surfacing is 200°C;

[0037] (5) Hardfacing

[0038] Carry out o...

Embodiment 2

[0046] A submerged arc welding surfacing process, comprising the steps of:

[0047] (1) Overlay inspection

[0048] First check the integrity of the surfacing weldment;

[0049] (2) Pretreatment

[0050] Grind the surface of the welded overlay after inspection with an angle grinder, and then use acetone to remove scale and oil;

[0051] (3) Washing and drying with water

[0052] The surface of the pre-treated surfacing weldment is washed with water, and then the drying process is carried out. The drying temperature is 60°C, and the drying time is 25 minutes. The surface washing is divided into three-stage washing, and the three-stage The water washing includes first-level water washing, second-level circulating pure water washing and third-level fresh pure water washing;

[0053] (4) Preheating

[0054] Preheat the dried surfacing in the preheating chamber for 1.5 hours, and the temperature of the preheated surfacing is 250°C;

[0055] (5) Hardfacing

[0056] Carry out ...

Embodiment 3

[0064] A submerged arc welding surfacing process, comprising the steps of:

[0065] (1) Overlay inspection

[0066] First check the integrity of the surfacing weldment;

[0067] (2) Pretreatment

[0068] Grind the surface of the welded overlay after inspection with an angle grinder, and then use acetone to remove scale and oil;

[0069] (3) Washing and drying with water

[0070] The surface of the pre-treated surfacing weldment is washed with water, and then the drying process is carried out. The drying temperature is 70 ° C, and the drying time is 30 minutes. The surface washing is divided into three stages of water washing, and the three stages The water washing includes first-level water washing, second-level circulating pure water washing and third-level fresh pure water washing;

[0071] (4) Preheating

[0072] Preheat the dried surfacing in the preheating chamber for 2 hours, and the temperature of the preheated surfacing is 300°C;

[0073] (5) Hardfacing

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com