Synthesis method of cyclohexane dimethanol, catalyst and application thereof

A technology of cyclohexanedimethanol and a synthesis method, which is applied in the field of synthesis of cyclohexanedimethanol, can solve the problems of increased cost, lengthened process flow, reduced production efficiency, etc., and achieves improved production efficiency, simplified process flow, cost reduction and the like. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

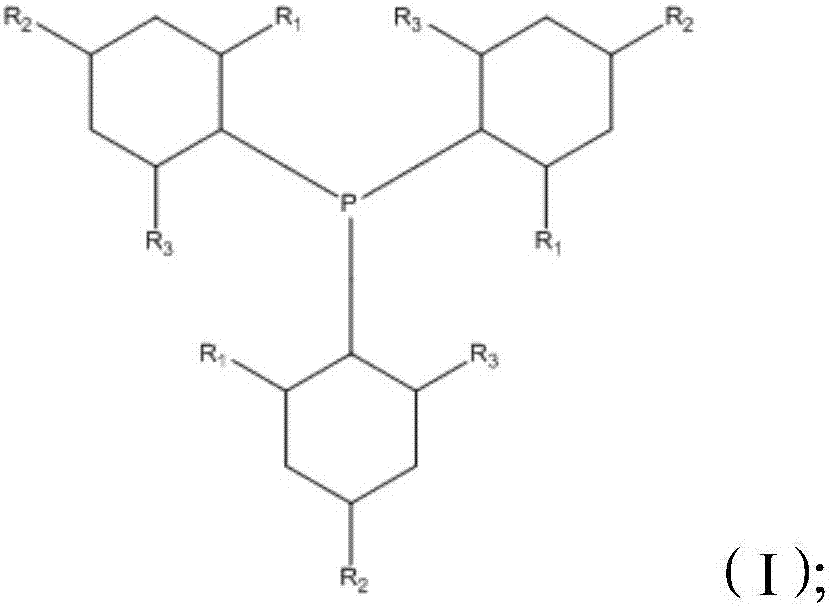

[0054] The three (2,4-di-tert-butylcyclohexyl) phosphine ligand used in the catalyst of this embodiment is prepared with reference to the following steps:

[0055] In the four-neck flask equipped with stirrer, reflux condenser, desiccator, constant pressure dropping funnel, thermometer and nitrogen protection device, add 20mL toluene; under nitrogen protection, add 2.7g metal sodium, start heating; when the temperature When the temperature rises to 90-100°C, the metallic sodium begins to melt, turn on the electric stirring, add 2.4mL of isoamyl alcohol, and stir to make the molten sodium disperse into fine off-white particles "sodium sand"; stop heating and cool down rapidly. When the temperature drops to about 75°C, add 2g of 2,4-di-tert-butylchlorobenzene dropwise under continuous stirring; when the temperature rises, keep the reaction temperature between 75-80°C, slowly add 10g of 2,4- Add di-tert-butylchlorobenzene for about 30 minutes, then keep it warm for 50 minutes; th...

Embodiment 2

[0065] Preparation of 3-cyclohexene-1-carbaldehyde:

[0066] Add 20g of cyclohexanedimethanol as a solvent to a stainless steel pressurized stirring tank with a volume of 50ml, heat up to melt and keep the temperature at 150°C, replace with nitrogen three times and keep the pressure at 4Mpa; add 4.8g of acrolein and 6.2g of 1,3-butane Diene. Under the condition of stirring, the temperature was maintained at 150° C. and the pressure was 4 MPa to react for 3 hours.

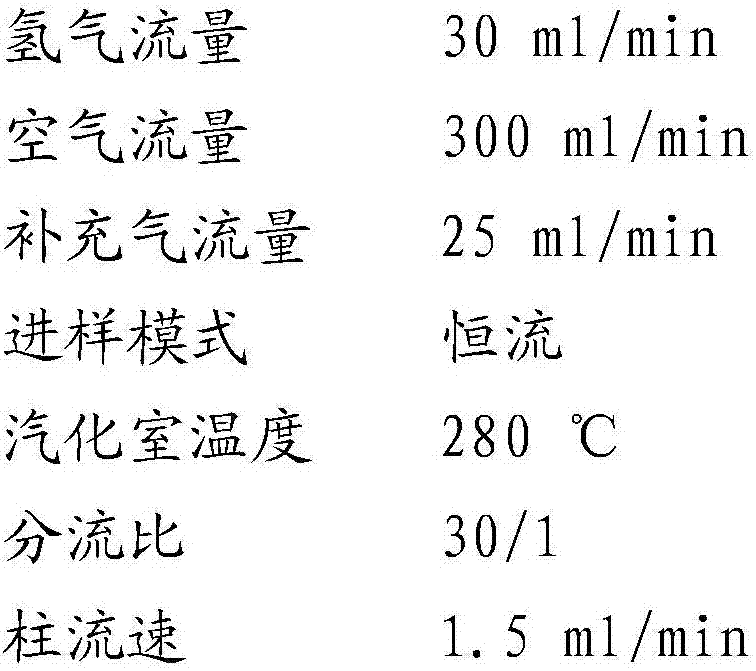

[0067] Sampling was carried out for GC (gas chromatography) analysis, and the yield of cyclohexene formaldehyde in terms of acrolein was >91%. Remove unreacted acrolein and butadiene by intermittent rectification under normal pressure, collect the top composition with a boiling point of 163-164°C, and obtain 3-cyclohexene- 1- Formaldehyde, spare.

[0068] Preparation of 1,4-cyclohexanedimethanol:

[0069] In the 50ml stainless steel reaction kettle, add 20g solvent (solvent is 1,4-cyclohexanedimethanol, 4-hydroxym...

Embodiment 3

[0071] The tricyclohexylphosphine ligand used in the catalyst of this example was provided by Jiangsu Sinoco Catalyst Co., Ltd., with a purity of 98%.

[0072] The synthetic method that present embodiment prepares cyclohexanedimethanol is as follows:

[0073] In a 50ml stainless steel reaction kettle, a mixture of 20g of cyclohexanol and methyl tert-butyl ether was added as a solvent, wherein the mass contents of cyclohexanol and methyl tert-butyl ether were 70%: 30%, respectively. Replace with nitrogen and synthesis gas three times in sequence, and then continue to flow synthesis gas. The composition of synthesis gas is CO and H with a volume ratio of 1:2. 2 , and maintain a pressure of 28Mpa. Add 0.03 g of precursor C 3 h 7 CCo 3 (CO) 9 , and 4 g of the aforementioned tricyclohexylphosphine as a catalyst, stirred at 110° C. for 30 min, during which the precursor was transformed into a hydrogenated polycarbonyl compound of cobalt. Take 50g of 3-cyclohexene-1-formaldehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com