Water-soluble quantum epoxy acrylate emulsion as well as preparation method and application thereof

A technology of epoxy acrylic acid and water-based acrylic acid, applied in the direction of coating, etc., can solve the problems that the water resistance of glass coating cannot be satisfied, the water resistance of coating is not ideal, and the appearance of products is affected, so as to achieve convenient application, strong adhesion, and improved burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

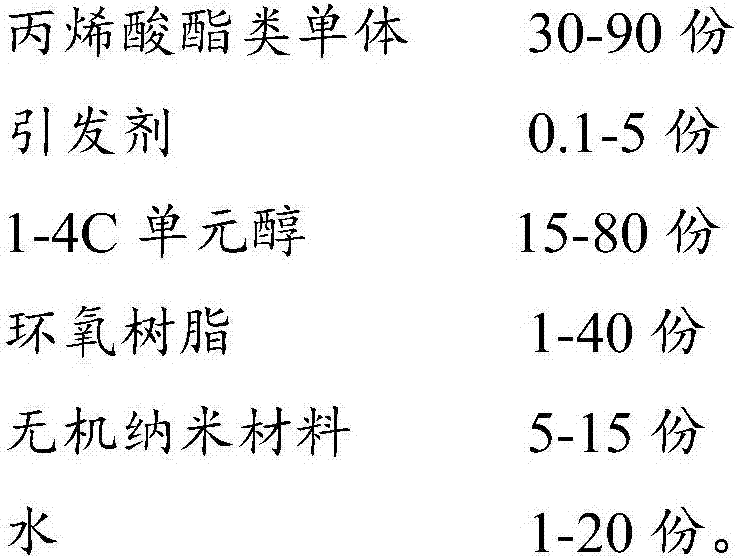

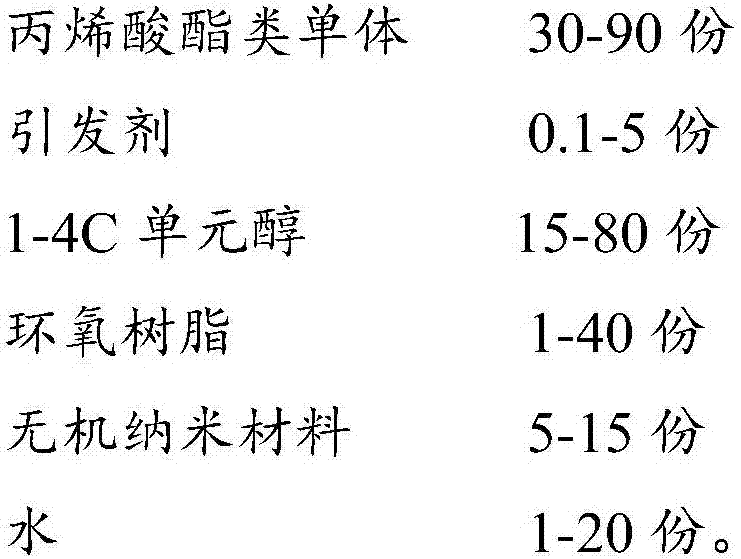

Method used

Image

Examples

preparation example Construction

[0061] Correspondingly, the present invention also provides a kind of preparation method of water-soluble quantum epoxy acrylic emulsion, comprising:

[0062] (1) mixing, stirring and dissolving the acrylate monomer and 75-95% initiator according to the formula to obtain a mixed solution;

[0063] (2) Add 1-4C unit alcohols, epoxy resins, and inorganic nanomaterials into the reactor, heat up to the boiling point of the solution and reflux for 1-5min, then drop the mixed solution prepared in step (1) to carry out free radical polymerization, and control The feed liquid is dropped within 1-5 hours, wherein, during the feeding process of the feed liquid, the temperature in the reaction kettle is kept between the boiling point of the solution in the kettle, and the temperature is between 80-120°C.

[0064] Preferably, 1-4C unit alcohols, epoxy resins, and inorganic nanomaterials are added to the reactor, heated to the boiling point of the solution and refluxed for 2-3 minutes, and...

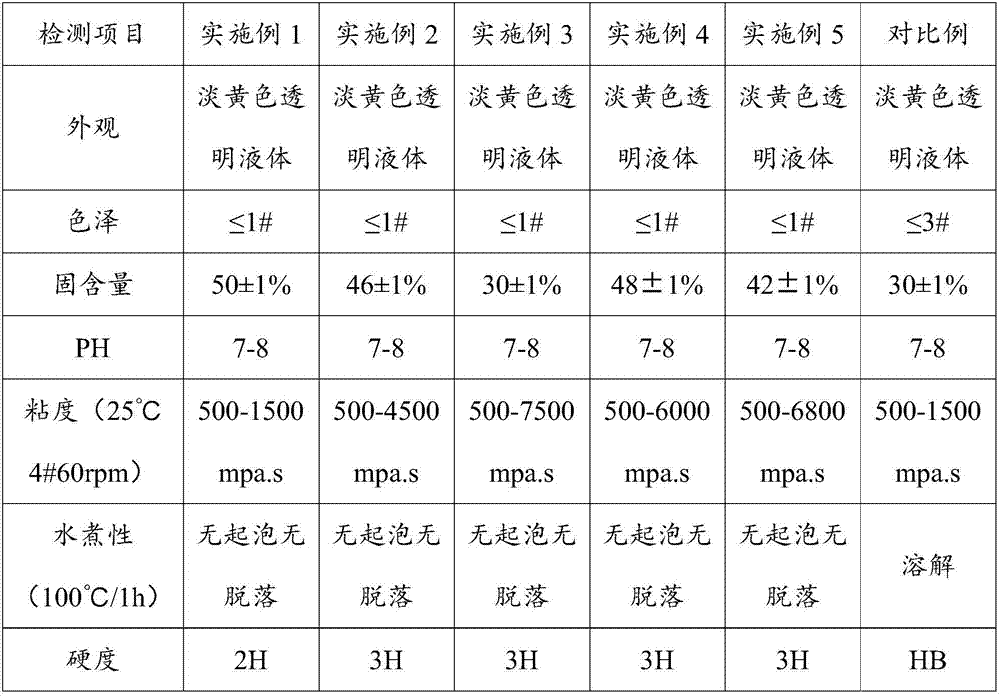

Embodiment 1

[0077] 1. Synthesis of solvent-based nano-epoxy modified acrylic resin: 12g of butyl acrylate, 26g of methyl methacrylate, 5g of acrylic acid, and 2.0g of benzoyl peroxide were mixed, stirred and dissolved evenly, and added to the dropping funnel for later use. 42g ethylene glycol butyl ether, 28g E-44 epoxy resin, 11g nano silicon dioxide are added in the four-necked flask that stirrer, condenser, thermometer, heater and drop feeder are housed, be heated up to solution boiling point reflux 2 Minutes, start to drop the mixed material liquid in the dropping funnel to carry out radical polymerization reaction, control the material liquid to drop in 2 hours. During the dropwise addition of feed liquid, the temperature in the reactor is kept at the boiling point of the solution in the reactor (between 75 and 88° C.). After the dropwise addition of the feed liquid is completed, keep the solution boiling for 3 hours, then add 0.5 g of initiator benzoyl peroxide, and then keep the te...

Embodiment 2

[0080] 1. Synthesis of solvent-based nano-epoxy modified acrylic resin: 19g butyl acrylate, 21g E-51 epoxy resin, 19g methyl methacrylate, 7g ethyl acrylate, 4g acrylic acid, 9g mixed nanomaterials and 1g peroxide Benzoyl is mixed and stirred to dissolve evenly, and added to the dropping funnel for later use. 35g isopropanol is added in the four-necked flask that agitator, condenser, thermometer, heater and dropping funnel are housed, be warmed up to solution boiling point and reflux for 3 minutes, start dripping feed liquid and carry out radical polymerization reaction, control feed liquid in The dripping is completed within 3 hours, and the temperature in the reactor is kept at the boiling point of the solution in the reactor (between 75 and 85° C.). After the dropwise addition of the feed liquid is completed, keep the solution boiling for 4 hours, then add 0.2 g of initiator benzoyl peroxide, and then continue the heat preservation for 4 hours to detect the solid content. W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com