g-C3N4 two-dimensional nanosheet film which can be used for gas separation as well as preparation method of film and application in gas separation

A two-dimensional nano, gas separation technology, applied in separation methods, semi-permeable membrane separation, greenhouse gas capture, etc., can solve problems such as solvent hazards, cumbersome nanosheet processes, easy to pollute the environment, etc., and achieve low cost and broad application prospects. , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Put melamine in a tube furnace, heat-treat at 3°C / min to 600°C for 3 hours under nitrogen atmosphere, then cool down to 30°C at 3°C / min to obtain agglomerated g-C 3 N 4 ;

[0048] (2) The calcined agglomerated g-C 3 N 4 Grind into powder, take 500mg calcined g-C 3 N 4 Disperse the powder in 1000ml N,N-dimethylformamide (DMF), sonicate for 8 hours and then let stand for 10 hours; then centrifuge at 3000r / min for 20min, take the supernatant, and repeat the centrifugation for 3 times until the supernatant is free of Precipitate to get g-C 3 N 4 The two-dimensional nanosheet solution has a concentration of 0.01 mg / ml measured by a UV-visible spectrophotometer, and is stored at 0°C;

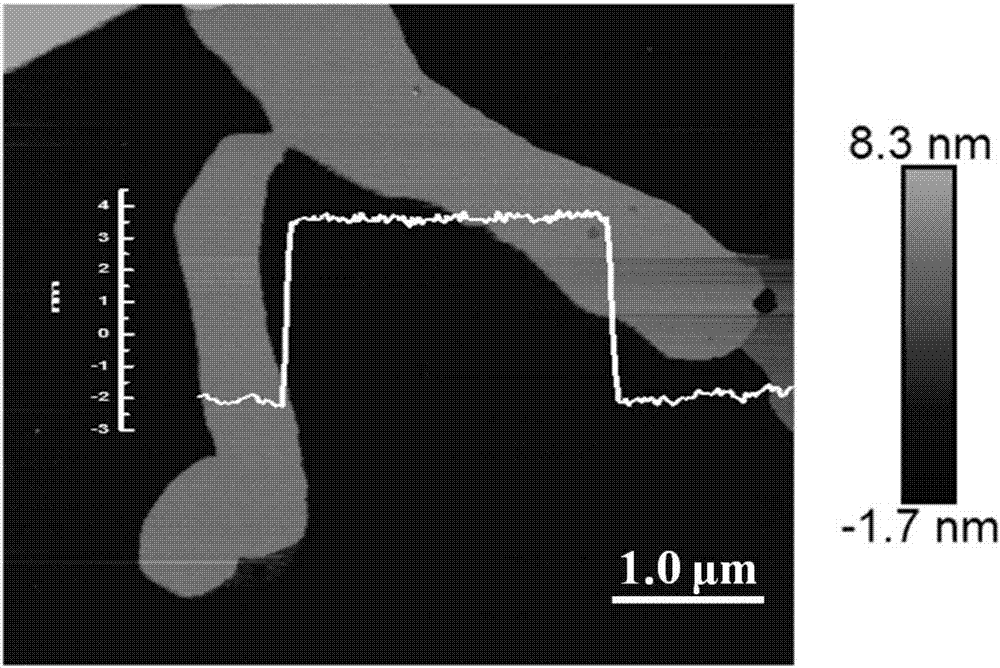

[0049] To the g-C that step (2) obtains 3 N 4 g-C in two-dimensional nanosheet solution 3 N 4 Two-dimensional nanosheets were tested by atomic force microscopy (AFM), and the results were as follows figure 1 shown by figure 1 It can be seen that: g-C 3 N 4 The thickness of th...

Embodiment 2

[0056] (1) Put melamine in a tube furnace, heat it at 2°C / min to 500°C for 10 hours under nitrogen atmosphere, and then cool it down to 30°C at 2°C / min to obtain agglomerated g-C 3 N 4 ;

[0057] (2) The calcined agglomerated g-C 3 N 4 Grind into powder, take 1g calcined g-C 3 N 4 Disperse the powder in 1000ml of N-methyl-pyrrolidone (NMP), sonicate for 4 hours and let it stand for 8 hours; then centrifuge at 5000r / min for 20 minutes, take the supernatant, and repeat the centrifugation for 3 times until the supernatant has no precipitation. get g-C 3 N 4 The two-dimensional nanosheet solution has a concentration of 0.005 mg / ml measured by a UV-visible spectrophotometer, and is stored at -4°C;

[0058] (3) Soak the polysulfoneamide membrane with a pore size of 180nm in 2mg / mL dopamine hydrochloride solution for 22h, and then make the g-C 3 N 4 Two-dimensional nanosheets deposited on polysulfoneamide membranes to form g-C 3 N 4 Two-dimensional nanosheet membrane, and ...

Embodiment 3

[0063] (1) Put cyanamide in a tube furnace, heat it at 5°C / min to 800°C for 2 hours under nitrogen atmosphere, and then cool down to 30°C at 5°C / min to obtain agglomerated g-C 3 N 4 ;

[0064] (2) The calcined agglomerated g-C 3 N 4 Grind into powder, take 2g calcined g-C 3 N 4 Disperse the powder in 1000ml formamide, sonicate for 24 hours and let it stand for 12 hours; then centrifuge at 8000r / min for 20 minutes, take the supernatant, and repeat the centrifugation for 3 times until the supernatant has no precipitation, you can get g-C 3 N 4 The two-dimensional nanosheet solution has a concentration of 0.02 mg / ml measured by an ultraviolet-visible spectrophotometer, and is stored at 4°C;

[0065] (3) Soak the sulfonated polysulfone membrane with a pore size of 200nm in a Nafion solution with a mass concentration of 5% for 24h, and then make the g-C 3 N 4 Two-dimensional nanosheets deposited on sulfonated polysulfone membranes to form g-C 3 N 4 Two-dimensional nanoshe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com