Ultra-thin two-dimensional layered material nanosheet and preparing method thereof

A two-dimensional layered and nanosheet technology, applied in the field of two-dimensional nanomaterials, can solve the problems of low yield of two-dimensional layered material nanosheets, difficulty in obtaining high-concentration suspensions, and restrictions on practical applications, and achieve good results. The effect of industrial application prospects, less demand for raw materials and equipment types, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ①. Weigh 0.2g of high-purity graphite initial powder into a 50mL centrifuge tube, put the centrifuge tube into an insulated bucket filled with liquid nitrogen and inject 40mL of liquid nitrogen, and place it in the liquid nitrogen insulated bucket Medium heat preservation for 0.5 hours;

[0028] ②. Take out the centrifuge tube, and immediately disperse the above-mentioned graphite powder in 1000mL of ethanol and water mixed solvent with a volume ratio of 1:1 after the liquid nitrogen is completely volatilized, and perform ultrasonic treatment for 0.5 hours with an ultrasonic power of 120W to obtain graphene nanosheets .

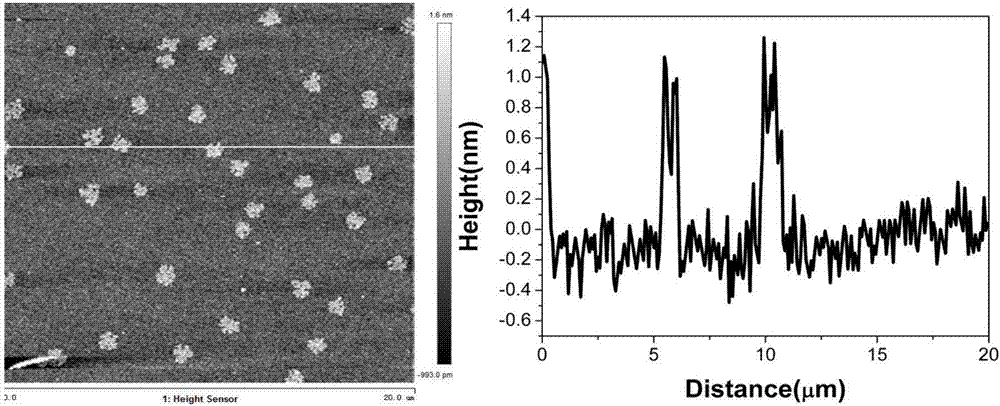

[0029] see figure 1 The AFM image of the graphene nanosheets shown, the graphene nanosheets prepared in this embodiment have a single-layer or few-layer structure, with a thickness of 0.8-1.6 nm and a size of 0.5-2 μm.

Embodiment 2

[0031] ①. Weigh 0.4g of high-purity graphite initial powder into a 50mL centrifuge tube, put the centrifuge tube into an insulated bucket filled with liquid nitrogen and inject 40mL of liquid nitrogen, and place it in the liquid nitrogen insulated bucket Medium heat preservation for 1 hour;

[0032] ②. Take out the centrifuge tube, and immediately disperse the above graphite powder in 1000mL isopropanol and water mixed solvent with a volume ratio of 1:1 after the liquid nitrogen is completely volatilized, and perform ultrasonic treatment for 1 hour, with an ultrasonic power of 150W, to obtain graphene nanoparticles. piece.

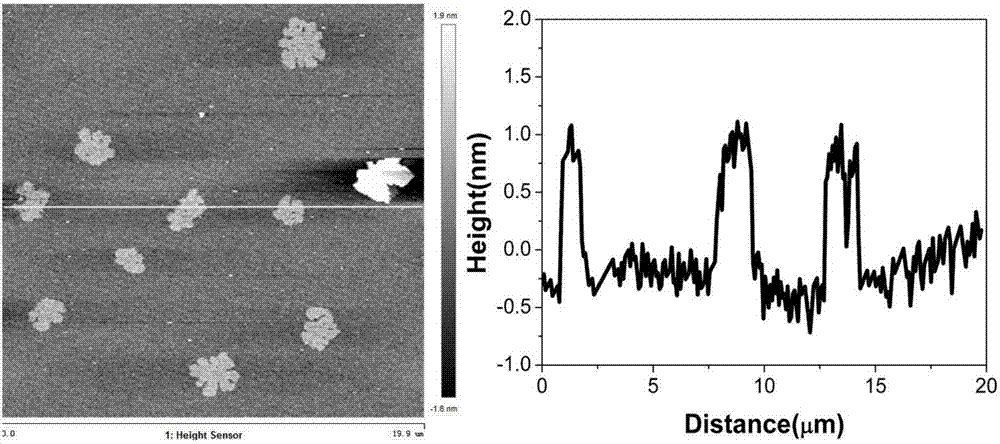

[0033] see figure 2 The AFM image of the graphene nanosheets shown, the graphene nanosheets prepared in this embodiment have a single-layer or few-layer structure, with a thickness of 1-1.7 nm and a size of 1-5 μm.

Embodiment 3

[0035] ①. Weigh 0.8g of high-purity molybdenum disulfide initial powder into a 50mL centrifuge tube, put the centrifuge tube into an insulated bucket filled with liquid argon and inject 40mL of liquid argon, and place it in the liquid argon Keep warm for 2 hours in an insulated bucket;

[0036] ②. Take out the centrifuge tube, and immediately after the liquid argon is completely volatilized, disperse the molybdenum disulfide powder in 1000mL of a mixed solvent of ethylene glycol and water with a volume ratio of 7:3, and perform ultrasonic treatment for 1.5 hours with an ultrasonic power of 180W to obtain two Molybdenum sulfide nanosheets.

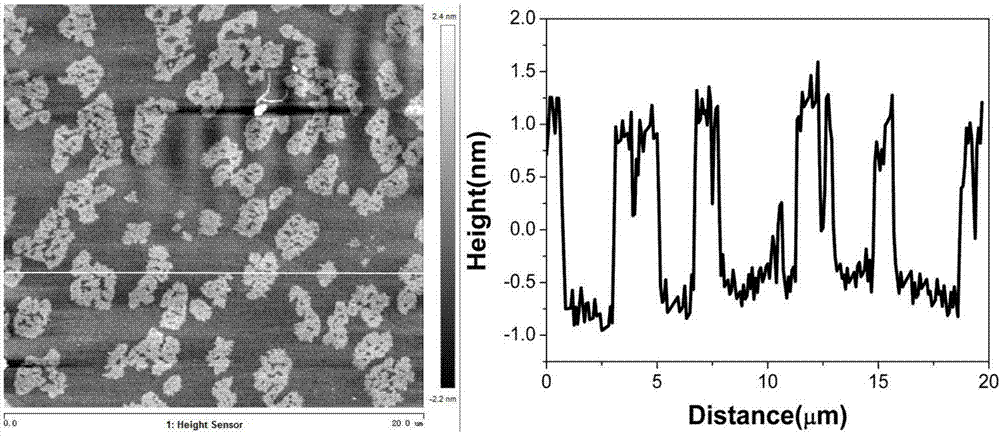

[0037] see image 3 The AFM images of molybdenum disulfide nanosheets are shown. The molybdenum disulfide nanosheets prepared in this example have a single-layer or few-layer structure, with a thickness of 1.5-2.5 nm and a size of 1-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com