Protocatechualdehyde cross-linked collagen hydrogel and preparation method thereof

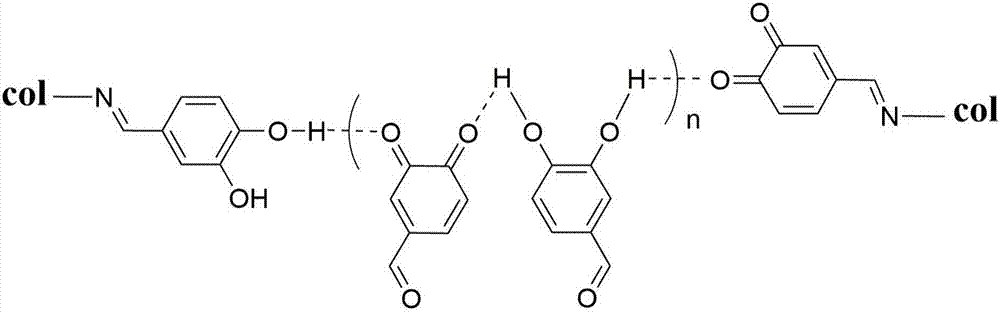

A technology of cross-linking collagen and catechin aldehyde, which is applied in the field of catechin aldehyde cross-linking collagen hydrogel and its preparation, can solve the problems of limited application and unsatisfactory effect, and achieve improved enzymolysis resistance and good biological functionality , Improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

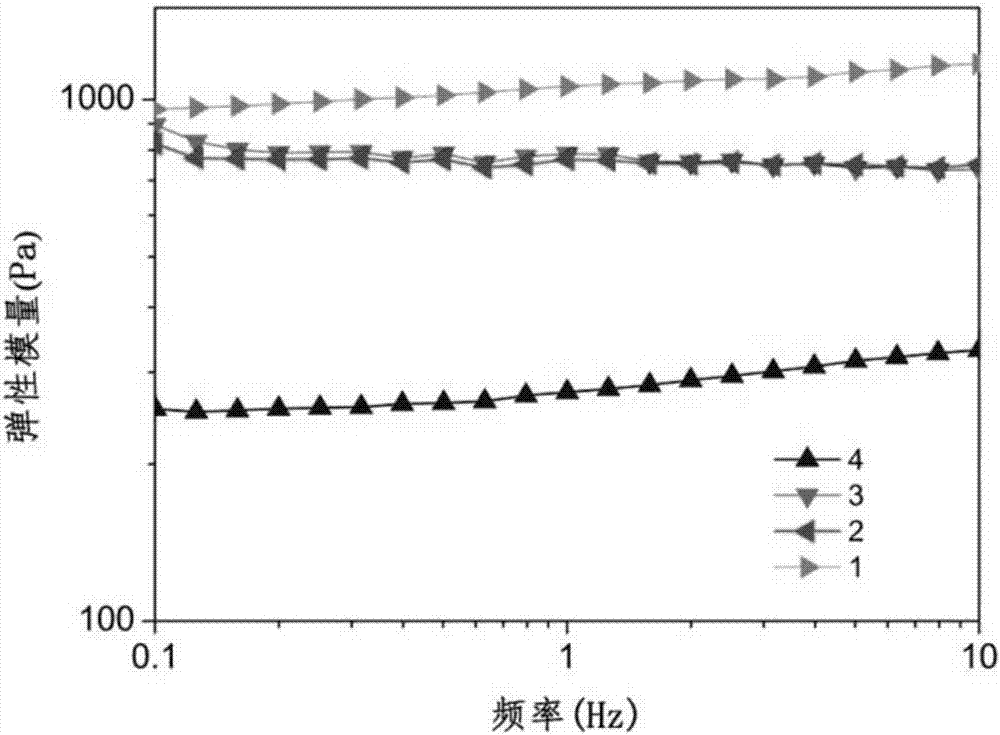

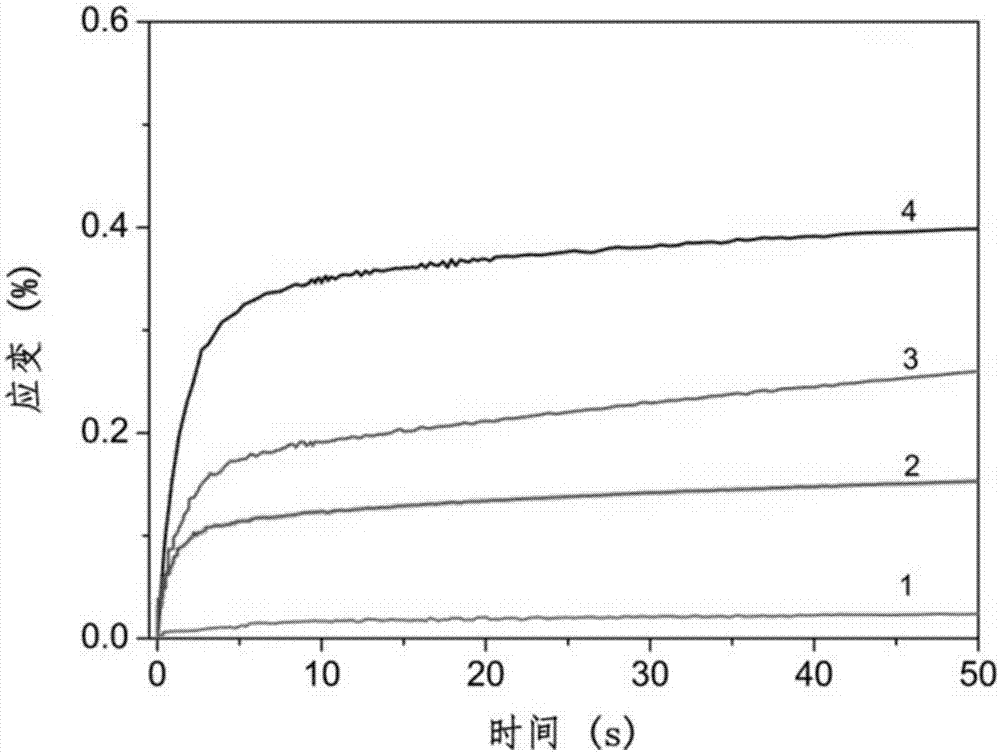

Examples

Embodiment 1

[0034] 1) Preparation of collagen solution: Clean all the glass instruments to be used in the experiment and dry them for later use. Add 20ml of acetic acid solution with a molar concentration of 0.01mol / L and 0.1g of collagen sponge in a 50mL beaker, and place on a magnetic stirrer. Stir until the collagen sponge is completely dissolved, add 1mL of phosphate buffer solution with a molar concentration of 200mmol / L to the solution, stir evenly, and then add dropwise a sodium hydroxide solution with a molar concentration of 1mol / L under an ice bath to adjust the concentration of the solution. pH to 7.4 to obtain a collagen solution with a concentration of 5 mg / mL;

[0035] 2) Preparation of collagen fibers: Take 2 mL of the collagen solution in step 1) and transfer it to a 20×20 mm weighing bottle, and then place it in a water bath at 37°C for 2 hours to allow the collagen molecules to self-assemble into collagen after incubation fiber;

[0036] 3) Grafting reaction: take the c...

Embodiment 2~4

[0040] In Examples 2-4, according to the technical solution provided by the present invention, the ratio of raw materials and reaction conditions were adjusted within the given range, and the specific ratio of raw materials and reaction conditions are shown in Table 1.

[0041] Table 1

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com