Halogen-free flame-retardant TPU encapsulation material and preparation method thereof

A technology of encapsulation and flame retardant, which is applied in the field of chemical synthesis and can solve the problems of poor product fluidity, insufficient physical strength, and molten droplets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

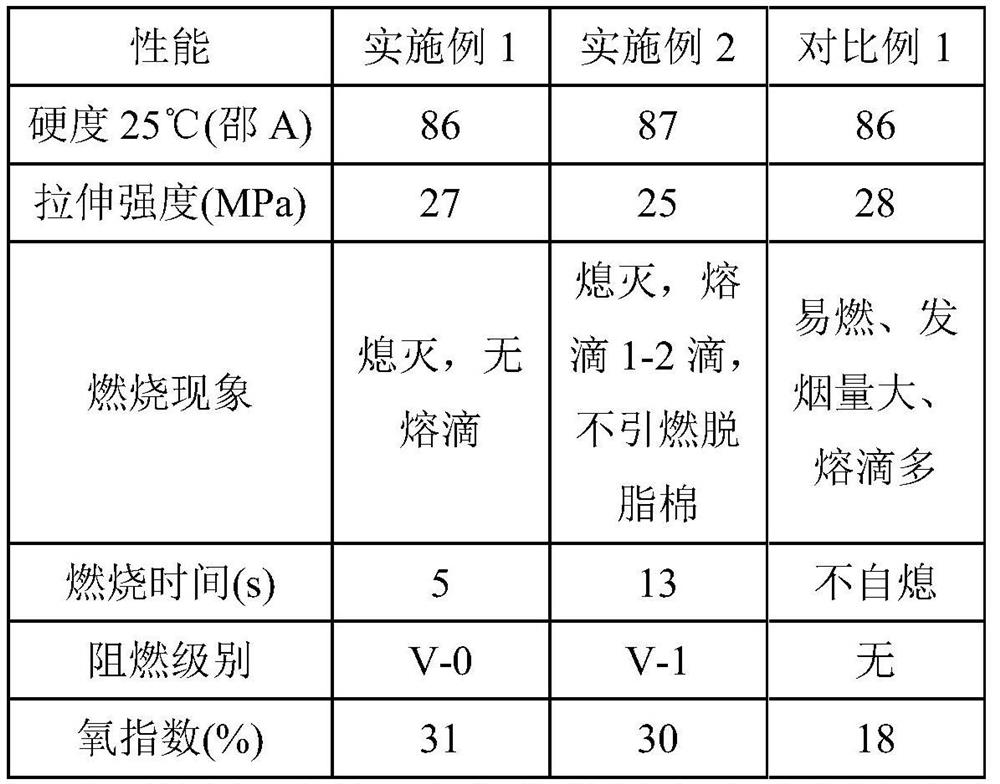

Embodiment 1

[0038] In terms of parts by weight, polytetrahydrofuran glycol (PTMG-1000): 38.45 parts are added to reactor A, and the set temperature is 105°C; MDI-100: 17.75 parts, placed in reactor B, and the set temperature is 65°C ; 1,4-butanediol: 2.96 parts, placed in the C reactor, set the temperature at 60°C; the mixed material was injected into the twin-screw reactor, the isocyanate index was controlled at 0.99-1.03, and passed through the side with a metering and mixing system Add flame retardant aluminum diethyl hypophosphite dispersed with 8 parts of plasticizer diethylene glycol dibenzoate to the feed port: 13 parts, flame retardant melamine polyphosphate: 9 parts, flame retardant hydroxide Magnesium: 5 parts, 0.25 parts each of Irganox 1076, antioxidant 168, 0.15 parts each of Tinuvin 292, UV-P, catalyst (T-9): 0.04 parts, and then processed by screw extrusion injection and underwater pelletizing Granulate and dry to obtain the halogen-free flame-retardant TPU elastomer materi...

Embodiment 2

[0040] In terms of parts by weight, polytetrahydrofuran glycol (PTMG-2000): 49.06 parts are added to reactor A, and the set temperature is 98°C; MDI-100: 21.02 parts, placed in reactor B, and the set temperature is 55°C ; 1,4-butanediol: 5.39 parts, placed in the C reactor, set the temperature at 45 ° C, the mixed material was injected into the twin-screw reactor, the isocyanate index was controlled at 0.99-1.03, and passed through the side with a metering and mixing system Add aluminum diethyl hypophosphite dispersed with 4 parts of plasticizer diethylene glycol dibenzoate: 9 parts, melamine cyanurate: 6 parts, aluminum oxide: 3 parts, Irganox 1010, anti Each 0.15 part of oxygen agent 626, each 0.1 part of Tinuvin 770, Tinuvin 328, catalyst (T-9): 0.03 part, then through screw extrusion injection processing, granulate and dry by the mode of underwater pelletizing, obtain the non- Halogen flame retardant TPU elastomer material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com