Halogen-free flame retardant TPU (Thermoplastic Urethane) glue coating material and preparation method thereof

A technology of encapsulation and flame retardant, which is applied in the field of chemical synthesis, can solve problems such as insufficient physical strength, uneven mixing and dispersion of solid additives and TPU products, and poor fluidity of products, so as to improve high temperature resistance and continuous performance, avoid The effect of high temperature melting cracking and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

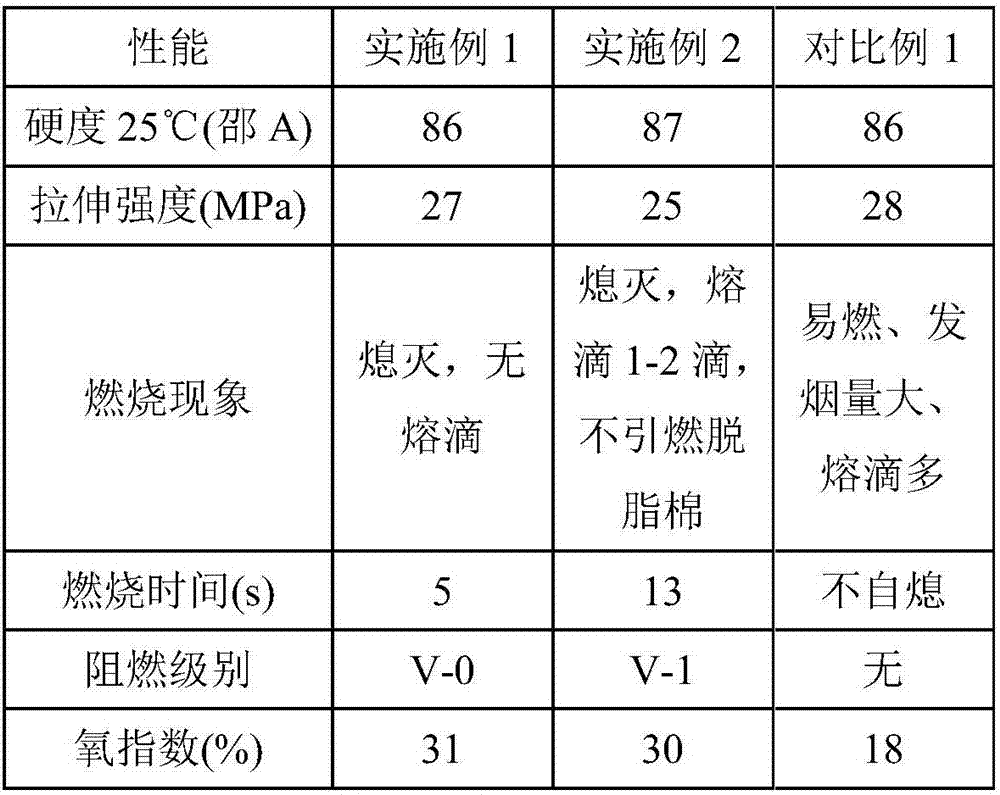

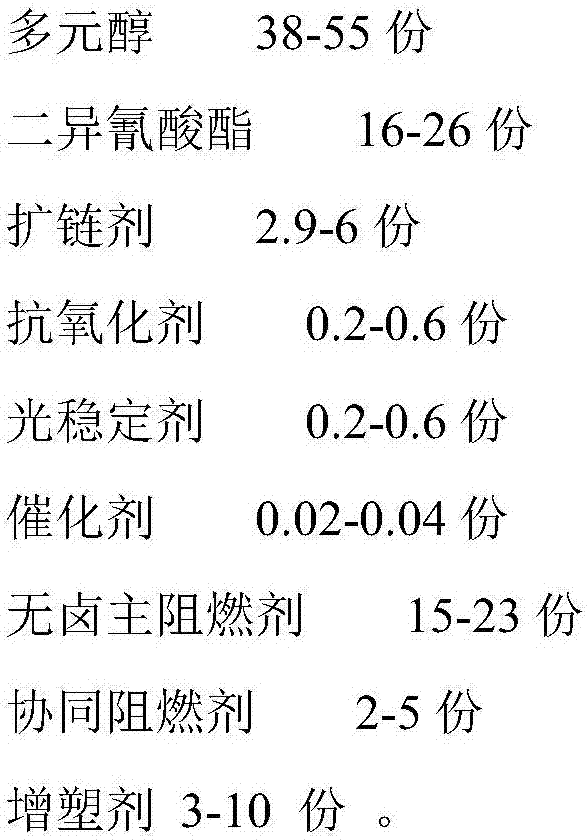

Embodiment 1

[0038] In terms of parts by weight, polytetrahydrofuran glycol (PTMG-1000): 38.45 parts are added to reactor A, and the set temperature is 105°C; MDI-100: 17.75 parts, placed in reactor B, and the set temperature is 65°C ; 1,4-butanediol: 2.96 parts, placed in the C reactor, set the temperature at 60°C; the mixed material was injected into the twin-screw reactor, the isocyanate index was controlled at 0.99-1.03, and passed through the side with a metering and mixing system Add flame retardant aluminum diethyl hypophosphite dispersed with 8 parts of plasticizer diethylene glycol dibenzoate to the feed port: 13 parts, flame retardant melamine polyphosphate: 9 parts, flame retardant hydroxide Magnesium: 5 parts, 0.25 parts each of Irganox 1076, antioxidant 168, 0.15 parts each of Tinuvin 292, UV-P, catalyst (T-9): 0.04 parts, and then processed by screw extrusion injection and underwater pelletizing Granulate and dry to obtain the halogen-free flame-retardant TPU elastomer materi...

Embodiment 2

[0040] In terms of parts by weight, polytetrahydrofuran glycol (PTMG-2000): 49.06 parts are added to reactor A, and the set temperature is 98°C; MDI-100: 21.02 parts, placed in reactor B, and the set temperature is 55°C ; 1,4-butanediol: 5.39 parts, placed in the C reactor, set the temperature at 45 ° C, the mixed material was injected into the twin-screw reactor, the isocyanate index was controlled at 0.99-1.03, and passed through the side with a metering and mixing system Add aluminum diethyl hypophosphite dispersed with 4 parts of plasticizer diethylene glycol dibenzoate: 9 parts, melamine cyanurate: 6 parts, aluminum oxide: 3 parts, Irganox 1010, anti Each 0.15 part of oxygen agent 626, each 0.1 part of Tinuvin 770, Tinuvin 328, catalyst (T-9): 0.03 part, then through screw extrusion injection processing, granulate and dry by the mode of underwater cutting, obtain the non- Halogen flame retardant TPU elastomer material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com