A kind of preparation method of extensible curing uv-led cationic curing adhesive

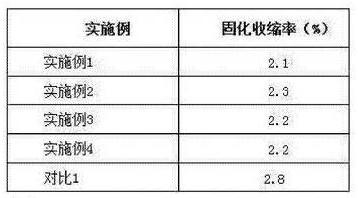

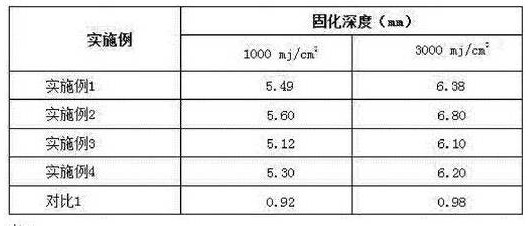

A UV-LED and cationic curing technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of difficult curing of the bottom adhesive layer and low curing depth of UV-LED cationic curing adhesives. Achieve the effect of improving curing speed and depth, excellent adhesion and mechanical properties, and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 59 parts of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate, 2 parts of triarylsulfonium hexafluorophosphate, 0.9 parts of N-vinylcarbazole, 1,2, 6 parts of 8,9-diepoxy-4-vinylcyclohexene, 0.06 parts of carbon black and 4 parts of γ-aminopropyltriethoxysilane were added to the stirred tank, and the pressure was -0.1 MPa. Stir for 0.5h, add 23 parts of silica powder and MoS 2 0.04 parts of nano hollow spheres, under the condition of -0.1 MPa, disperse at high speed for 0.6h, add 5 parts of meteorological silica, stir evenly, under the condition of -0.1 MPa, disperse and stir at high speed for 1h, and then discharge the material, that is, Extensible and curable UV-LED cationic curing adhesive; the speed of the high-speed stirring is 50 r / min for revolution and 1800 r / min for autorotation.

[0035] The MoS 2 Nano hollow spheres are carried out according to the following steps:

[0036] Add polyethylene glycol with a molecular weight of 15,000 into deionized wate...

Embodiment 2

[0038] 30 parts of bis-(3,4-epoxycyclohexylmethyl) adipate, 23 parts of bisphenol F epoxy resin, 3 parts of iodonium diaryl hexafluoroantimonate, 1-hydroxy-cyclohexyl -0.4 parts of phenyl ketone, 12 parts of 3,3'-(oxybismethylene)bis(3-ethyl)oxetane, 0.06 parts of Sudan black and γ-aminopropyl triethoxy Add 3.5 parts of silane into the stirred tank, stir for 0.5h under the condition of -0.1 MPa, add 23 parts of silicon micropowder and MoS 2 0.04 parts of nano hollow spheres, under the condition of -0.1 MPa, disperse at high speed for 0.6h, add 5 parts of meteorological silica, stir evenly, under the condition of -0.1 MPa, disperse and stir at high speed for 1h, and then discharge the material, that is, Extensible and curable UV-LED cationic curing adhesive; the speed of the high-speed stirring is 30 r / min for revolution and 800 r / min for autorotation.

[0039] The MoS 2 Nano hollow spheres are carried out according to the following steps:

[0040] Add polyethylene glycol wi...

Embodiment 3

[0043] 25 parts of 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester, 15 parts of hydrogenated bisphenol A epoxy resin, 3.5 parts of diaryl iodonium hexafluorophosphate, (2,4 , 0.4 parts of 6-trimethylbenzoyl) diphenylphosphine oxide, 20 parts of 1,2,8,9-diepoxy-4-vinylcyclohexene, 0.04 parts of titanium dioxide and γ-aminopropyl tri Add 3 parts of ethoxysilane into the stirred tank, stir for 0.5h under the pressure of -0.1 MPa, add 30 parts of silicon micropowder and MoS 2 0.06 parts of nano hollow spheres, under the condition of -0.1 MPa, disperse at high speed for 0.6h, add 2 parts of meteorological silica, stir evenly, under the condition of -0.1 MPa, disperse and stir at high speed for 1h, and then discharge the material, that is, Extensible curable UV-LED cationic curing adhesive; the speed of the high-speed stirring is 20 r / min for revolution and 1500 r / min for autorotation.

[0044] The MoS 2 Nano hollow spheres are carried out according to the following st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com