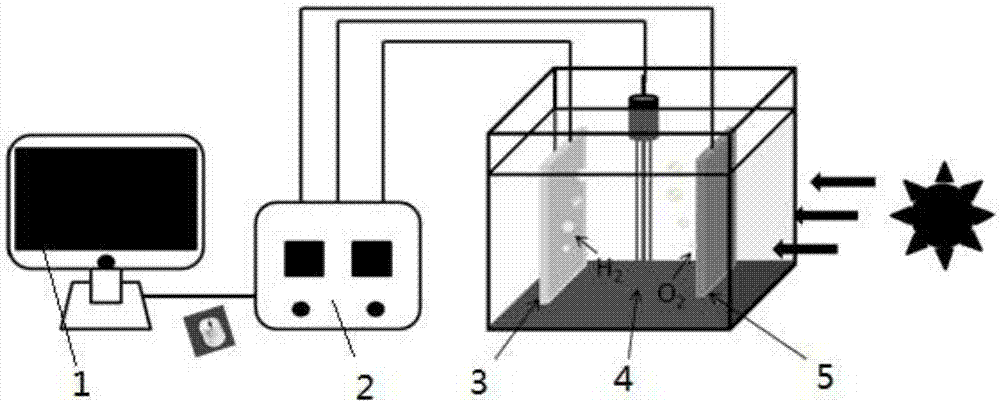

Semiconductor photoelectrode photocatalytic water splitting reaction device based on black silicon PN knots and manufacturing method thereof

A reaction device, PN junction technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of low light utilization rate of ordinary silicon wafers, achieve the effect of improving the efficiency of photolysis of water, reducing costs, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

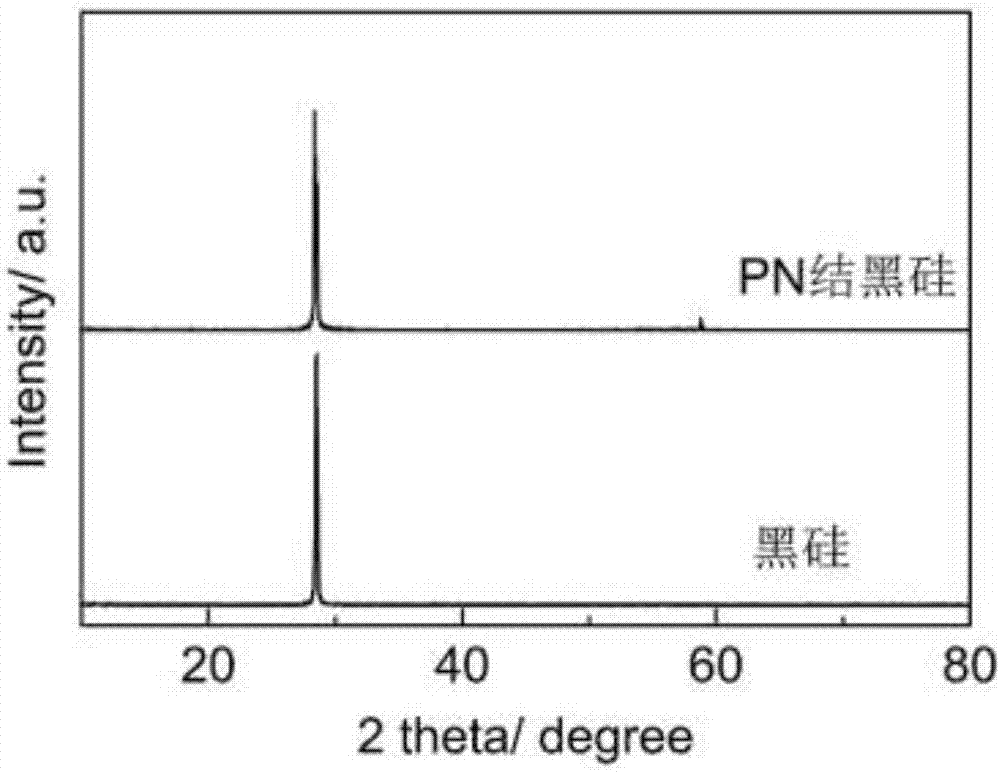

[0033] The preparation method of the black silicon PN junction photoelectrode is as follows:

[0034] (1) After micronizing the surface of ordinary P-type single crystal or polycrystalline silicon wafers to form black silicon, after low-temperature and low-concentration source diffusion process, the obtained black silicon wafers are preheated in a diffusion furnace at 750-800°C and passed through into low concentration O 2 , the flow rate is 0.1-0.2L / min, and the surface of the black silicon wafer is slightly oxidized in advance;

[0035] (2) Then feed POCl3 with a flow rate of 0.9-1.5L / min, and form a uniform black silicon PN junction after phosphorus diffusion at 800-870°C for 30-60 minutes;

[0036] (3) Finally, use hydrofluoric acid to remove the phosphosilicate glass layer on the surface of the PN junction black silicon.

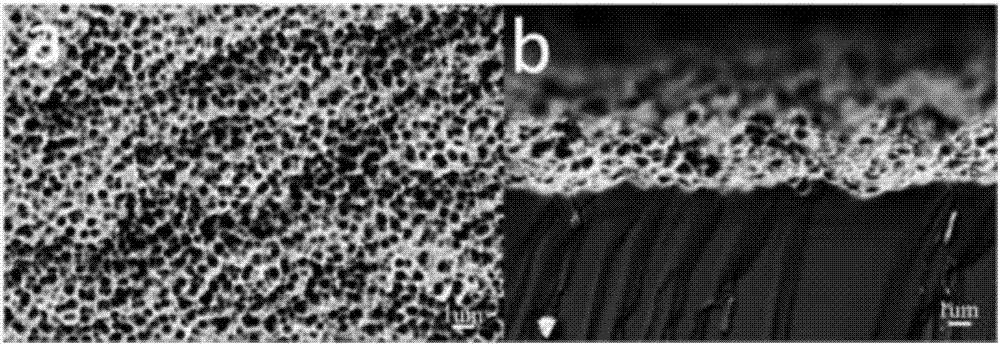

[0037] The surface micronanoization is a structure combining micro pits and nano pits, and the size of the nano pits is 10-900nm, and the depth is 10...

Embodiment 1

[0042] 1. Take a P-type polycrystalline silicon wafer, and prepare a polycrystalline black silicon wafer with a micro-nano structure by using Ag as a metal catalyst through the MACE method.

[0043] 2. Using phosphorus oxychloride (POCl 3 ) Liquid source diffusion process to prepare PN junction:

[0044] a) Place the textured black silicon wafer on a quartz boat, push it into the furnace chamber, and then raise the temperature to 800°C and feed nitrogen gas at a flow rate of 15L / min, and keep it warm for 15 minutes for preheating.

[0045] b) Pass O 2 , the flow rate is 0.1L / min, and the temperature is kept for 1.5min to pre-oxidize the micro-nano structure on the surface of the black silicon.

[0046] c) Introduce nitrogen with a flow rate of 5 L / min and keep warm for 5 minutes to pre-deposit micro-nano structures on the surface of the black silicon.

[0047] d) Raise the temperature to 810°C, feed in nitrogen and oxygen, keep it warm for 10 minutes, and carry out back-tempe...

Embodiment 2

[0059] 1. Take a P-type polycrystalline silicon wafer, and prepare a polycrystalline black silicon wafer with a micro-nano structure by using Ag as a metal catalyst through the MACE method.

[0060] 2. Adopt the same diffusion process steps as in Example 1, but change the step g) temperature to 870°C, and the process time is 18min, and other process parameters are the same as in Example 1 to prepare PN junction black silicon, which is measured by the four-probe method The average square resistance of the black silicon wafer is 103Ω / □.

[0061] 3. Assembling and constructing the photo-water splitting reaction device of black silicon PN junction: polycrystalline PN junction black silicon with a square resistance of 103Ω / □ is used as the photoelectrode, the saturated Ag / AgCl electrode is used as the reference electrode, and the Pt electrode is used as the counter electrode. The 0.2mol / L Na2SO4 solution was used as the electrolyte, and the photoelectric water splitting reaction de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com