Fermented fiber feed for pigs and preparation method thereof

A fiber and feed technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of difficulty in large-scale production, large feed ratio, and large loss of nutrients, so as to promote rapid growth, improve production capacity, and improve The effect of protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

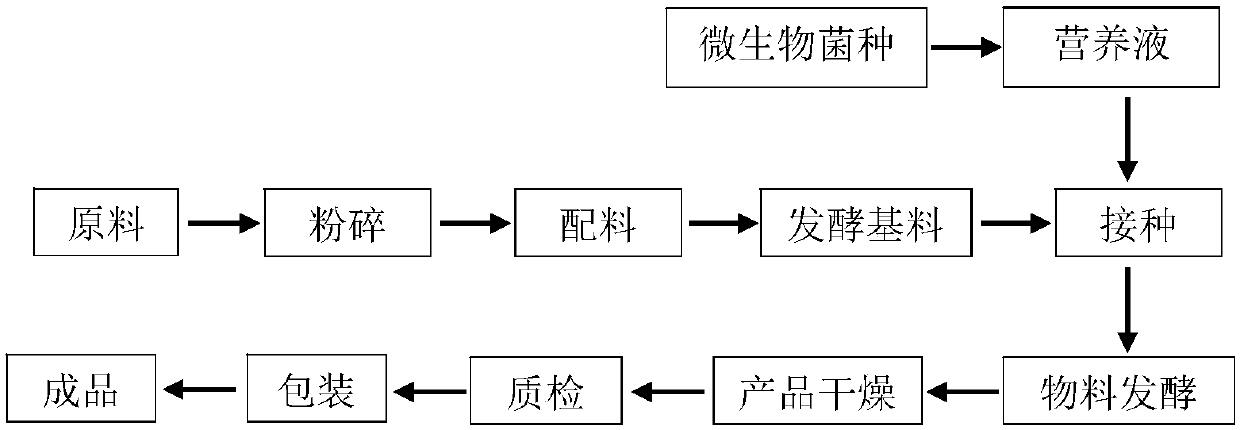

Image

Examples

Embodiment 1

[0050] Firstly, 5kg of fresh wheat bran was weighed as the fermentation base material, and then prepared with 2×10 7 cfu / mL yeast NKY1, 2×10 7 cfu / mL Bacillus subtilis, 2×10 7 cfu / mL Bacillus licheniformis, 2×10 7 cfu / mL Lactobacillus plantarum, 2×10 7 cfu / mL Lactobacillus reuteri LR1 mixed bacterial solution 5.0L, stir evenly, spray the mixed bacterial solution into the bran raw material, mix the material solution well, put the fermented base material after inoculation into the microorganism with one-way ventilation valve In the anaerobic fermentation bag, heat-melt the seal, place the fermentation bag in an environment of 32° C. for 48 hours to ferment for 48 hours, and obtain fermented fiber feed for pigs. After fermentation, the material was sampled to determine the number of live bacteria (plate count method), material pH, lactic acid content, mycotoxin content and protein content of Bacillus, Lactobacillus and yeast respectively. The results are shown in Table 1.

[...

Embodiment 2

[0061] Take by weighing fresh 4.5kg wheat bran and 0.5kg bean curd, mix well. Then make up 2 x 10 7 cfu / mL yeast NKY1, 2×10 7 cfu / mL Bacillus subtilis, 2×10 7 cfu / mL Bacillus licheniformis, 2×10 7 cfu / mL Lactobacillus plantarum, 2×10 7 cfu / mL Lactobacillus reuteri LR1 mixed bacterial solution 5.0L, stir well. Spray the mixed bacteria solution into the bran raw material, mix the material solution fully and evenly, put the fermented base material after inoculation into a microbial anaerobic fermentation bag with a one-way ventilation valve, seal it with hot melt, and place the fermentation bag in an environment of 32°C The fermented fiber feed for pigs was obtained by standing and fermenting for 48 hours. After fermentation, the material was sampled by measuring the number of live bacteria of Bacillus, Lactobacillus and yeast (plate count method), the pH value of the material, the content of lactic acid, the content of mycotoxin, and the content of protein. The results are ...

Embodiment 3

[0066] Take by weighing fresh 4.0kg wheat bran and 1.0kg bean curd, mix well. Then make up 2 x 10 7 cfu / mL yeast NKY1, 2×10 7 cfu / mL Bacillus subtilis, 2×10 7 cfu / mL Bacillus licheniformis, 2×10 7 cfu / mL Lactobacillus plantarum, 2×10 7 cfu / mL Lactobacillus reuteri LR1 mixed bacterial solution 5.0L, stir well. Spray the mixed bacteria solution into the bran raw material, mix the material solution fully and evenly, put the fermented base material after inoculation into a microbial anaerobic fermentation bag with a one-way ventilation valve, seal it with hot melt, and place the fermentation bag in an environment of 32°C The fermented fiber feed for pigs was obtained by standing and fermenting for 48 hours. After fermentation, the material was sampled by measuring the number of live bacteria of Bacillus, Lactobacillus and yeast (plate count method), material pH value, lactic acid content, mycotoxin content, and protein content. The results are shown in Table 3. The detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com