Fireproof and thermal-insulation composite for building

A technology of fire-proof thermal insulation and composite materials, which is applied in the field of fire-proof thermal insulation composite materials for buildings, can solve the problems of poor fire performance, reduced strength, and affect the overall performance, etc., so as to improve the fire retardant performance, improve the crack resistance, and improve the fire rating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

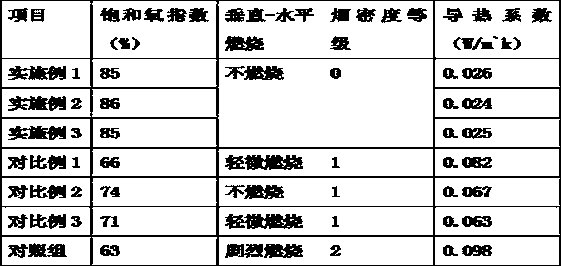

Embodiment 1

[0017] A fireproof and thermal insulation composite material for buildings, which is made of the following components in parts by weight: 150-160 parts of sulphoaluminate cement, 70-80 parts of high-density polyethylene, 60-70 parts of fly ash, and 45-50 parts of gypsum 30-40 parts of hollow microspheres, 20-25 parts of basalt fiber, 8-10 parts of sodium aluminate, 7-10 parts of anhydrous sodium sulfate, 4-6 parts of silicon dioxide, 3-5 parts of magnesium oxide, hydrogen 2-4 parts of calcium oxide, 2-3 parts of lithium carbonate, 1.5-2.0 parts of silicone water repellent, 1.0-1.5 parts of vinyl dimethyl siloxane, γ-aminopropyl triethoxysilane coupling agent 0.5-0.8 parts, 3.5-4.0 parts of paraffin, 25-30 parts of absolute ethanol, 100-110 parts of water, the preparation method comprises the following steps:

[0018] (1) Mix absolute ethanol and water at a mass ratio of 8-9:1, heat to 60-70°C, add γ-aminopropyltriethoxysilane coupling agent under stirring, and stir for 10-15 m...

Embodiment 2

[0025] A fireproof and thermal insulation composite material for buildings, which is made of the following components in parts by weight: 150-160 parts of sulphoaluminate cement, 70-80 parts of high-density polyethylene, 60-70 parts of fly ash, and 45-50 parts of gypsum 30-40 parts of hollow microspheres, 20-25 parts of basalt fiber, 8-10 parts of sodium aluminate, 7-10 parts of anhydrous sodium sulfate, 4-6 parts of silicon dioxide, 3-5 parts of magnesium oxide, hydrogen 2-4 parts of calcium oxide, 2-3 parts of lithium carbonate, 1.5-2.0 parts of silicone water repellent, 1.0-1.5 parts of vinyl dimethyl siloxane, γ-aminopropyl triethoxysilane coupling agent 0.5-0.8 parts, 3.5-4.0 parts of paraffin, 25-30 parts of absolute ethanol, 100-110 parts of water, the preparation method comprises the following steps:

[0026] (1) Mix absolute ethanol and water at a mass ratio of 8-9:1, heat to 60-70°C, add γ-aminopropyltriethoxysilane coupling agent under stirring, and stir for 10-15 m...

Embodiment 3

[0033] A fireproof and thermal insulation composite material for buildings, which is made of the following components in parts by weight: 150-160 parts of sulphoaluminate cement, 70-80 parts of high-density polyethylene, 60-70 parts of fly ash, and 45-50 parts of gypsum 30-40 parts of hollow microspheres, 20-25 parts of basalt fiber, 8-10 parts of sodium aluminate, 7-10 parts of anhydrous sodium sulfate, 4-6 parts of silicon dioxide, 3-5 parts of magnesium oxide, hydrogen 2-4 parts of calcium oxide, 2-3 parts of lithium carbonate, 1.5-2.0 parts of silicone water repellent, 1.0-1.5 parts of vinyl dimethyl siloxane, γ-aminopropyl triethoxysilane coupling agent 0.5-0.8 parts, 3.5-4.0 parts of paraffin, 25-30 parts of absolute ethanol, 100-110 parts of water, the preparation method comprises the following steps:

[0034] (1) Mix absolute ethanol and water at a mass ratio of 8-9:1, heat to 60-70°C, add γ-aminopropyltriethoxysilane coupling agent under stirring, and stir for 10-15 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com