Ti3C2-containing composite semipermeable membrane used for light evaporation of water, and preparation method and application of membrane

A composite semipermeable membrane and light evaporation technology, which is applied in the field of composite semipermeable membranes and new composite semipermeable membranes, can solve problems such as shedding, unfavorable light evaporation and water evaporation, and achieve low cost, good application prospects, and simple preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

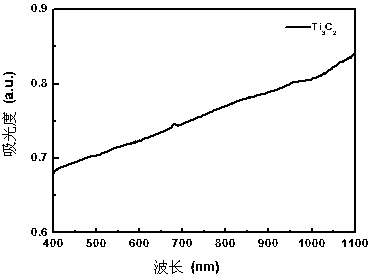

[0027] The invention provides a Ti-containing 3 C 2 The preparation method of composite semipermeable membrane, it comprises the following steps:

[0028] Step 1, put Ti 3 AlC 2The raw materials are added to the etchant, fully stirred for 12-18 h, and the rotation speed is 800-1500 r / min to obtain a suspension, and the suspension is centrifuged (the standard for centrifugal washing of the suspension is pH > 5), and vacuum-dried; The etchant is any one of hydrofluoric acid, lithium fluoride + hydrochloric acid (that is, a mixture of lithium fluoride and hydrochloric acid), sodium hydroxide + sulfuric acid (that is, a mixture of sodium hydroxide and sulfuric acid), and ammonium bifluoride ; Preferred mass fraction is 50% hydrofluoric acid;

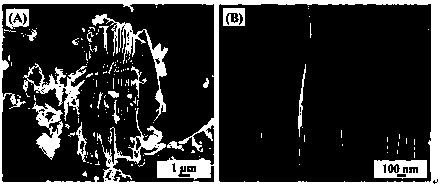

[0029] Step 2, put Ti 3 C 2 Mix the powder with the intercalation solvent for 15-18 h, centrifuge and dry in vacuum to prepare Ti with layered structure 3 C 2 Powder; the intercalation solvent is selected from any one of dimethyl sul...

Embodiment

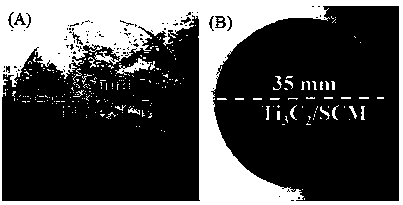

[0037] Layer 73.5 mg of Ti 3 C 2 The dry powder was added to 4 mL of the above-mentioned semipermeable membrane precursor solution, and stirred thoroughly for 90 min to obtain a uniform mixed solution. Take 2 mL from the above mixed solution, add it into a 500 mL beaker with a diameter of 75 mm, and let it dry naturally to form a film. The dried composite film was taken out, cut into a circular film with a diameter of 35 mm, and a black Ti-containing film with a thickness of about 150 μm and a content of 8 mg was prepared. 3 C 2 Composite semi-permeable membrane, its actual photo is as follows figure 2 (A) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com