Polysubstituted chiral (1-ethoxy)benzene and asymmetric synthesis method thereof

A synthetic method and multi-substitution technology, which is applied in the field of asymmetric synthesis of multi-substituted chiral benzene, can solve the problems of diacetylbenzene or triacetylbenzene raw materials are difficult to obtain and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Asymmetric synthesis of (S, S)-1,3-bis(1-hydroxyethyl)benzene

[0038]

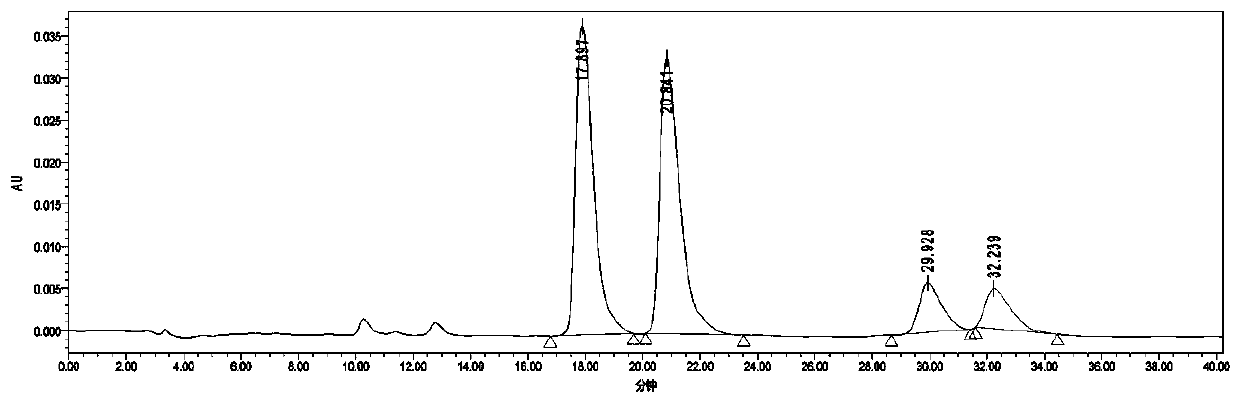

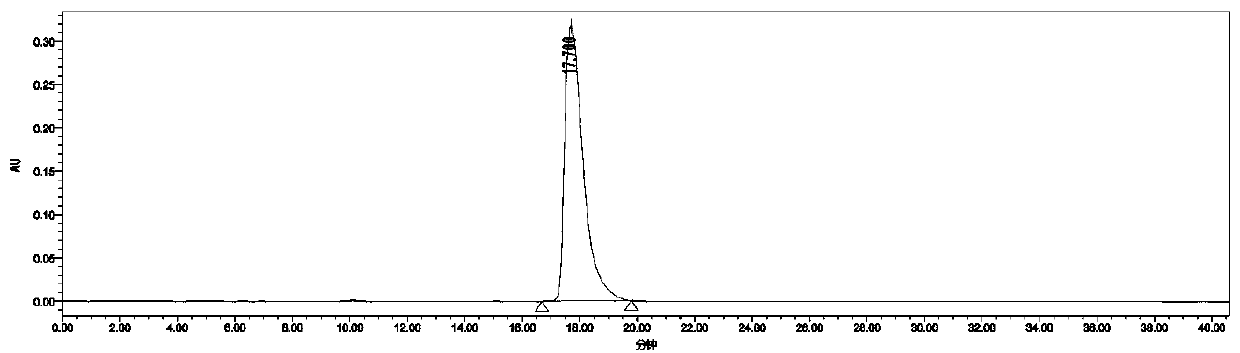

[0039] Add 0.5 mmol of m-diethynylbenzene into the test tube, followed by adding CF 3 SO 3 H (40mol%, 18uL), H 2 O(4 equvi., 40uL), CF 3 CH 2 OH (1mL), after reacting at 60°C for 48h, add 0.005mmol catalyst C, KOH (0.5mmol, 28mg), put the reaction test tube in a high-pressure reactor, replace it three times, then fill it with 4Mpa hydrogen, and react at 40°C for 24 Hour. After the reaction, wash with water, extract the aqueous phase with ethyl acetate 3 times, combine the organic phases and concentrate to dryness, the isolated yield: 86% (petroleum ether: ethyl acetate = 5:1) HPLC assay product (S, S)- The asymmetric synthesis of 1,3-di(1-hydroxyethyl)benzene has an enantiomeric excess value of 99%, a diastereomeric excess value of 99%, and HPLC separation conditions: chiral column Daicel OJ-H column , Mobile phase: n-hexane / isopropanol=90:10 (volume ratio), flow velocity: 1.0 m...

Embodiment 2

[0044] Example 2: Asymmetric synthesis of (S, S)-1,3-bis(1-hydroxyethyl)benzene

[0045]

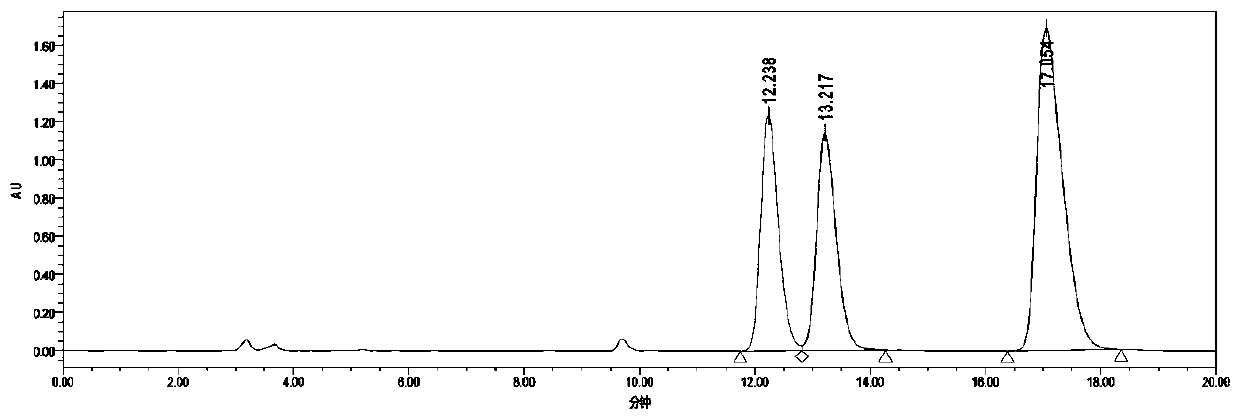

[0046] Add 0.5 mmol of m-diethynylbenzene into the test tube, followed by adding CF 3 SO 3 H (40mol%, 18uL), H 2 O(4 equvi., 40uL), CF 3 CH 2 OH (1mL), after reacting at 60°C for 48h, add 0.005mmol catalyst E, KOH (0.5mmol, 28mg), put the reaction test tube in a high-pressure reactor, replace it three times, then fill it with 4Mpa hydrogen, and react at 40°C for 24 Hour. After the reaction, wash with water, extract the aqueous phase with ethyl acetate 3 times, combine the organic phases and concentrate to dryness, the isolated yield: 62% (petroleum ether: ethyl acetate = 5:1) HPLC assay product (S, S)- The asymmetric synthesis of 1,3-bis(1-hydroxyethyl)benzene gave an enantiomeric excess of 89% and a diastereomeric excess of 91%.

Embodiment 3

[0047] Example 3: Asymmetric synthesis of (S, S)-1,3-bis(1-hydroxyethyl)benzene

[0048]

[0049] Add 0.5 mmol of m-diethynylbenzene into the test tube, followed by adding CF 3 SO 3 H (40mol%, 18uL), H 2 O(4 equvi., 40uL), CF 3 CH 2 OH (1mL), reacted at 60°C for 48h, added 0.005mmol of catalyst F, KOH (0.5mmol, 28mg), placed the reaction test tube in a high-pressure reactor, replaced 3 times, then filled with 4Mpa hydrogen, and reacted at 40°C for 24 Hour. After the reaction, wash with water, extract the aqueous phase with ethyl acetate 3 times, combine the organic phases and concentrate to dryness, the isolated yield: 71% (petroleum ether: ethyl acetate = 5:1) HPLC assay product (S, S)- The asymmetric synthesis of 1,3-bis(1-hydroxyethyl)benzene gave an enantiomeric excess of 83% and a diastereomeric excess of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com