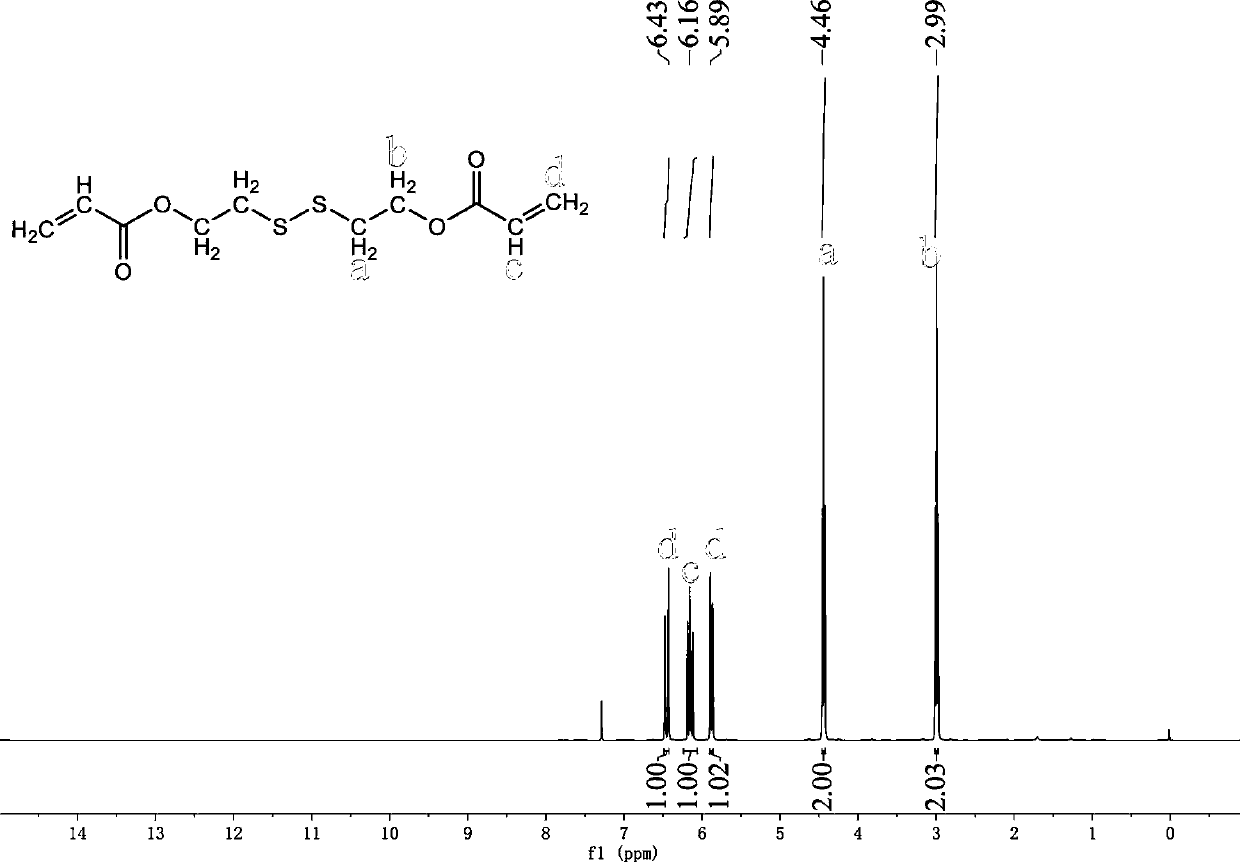

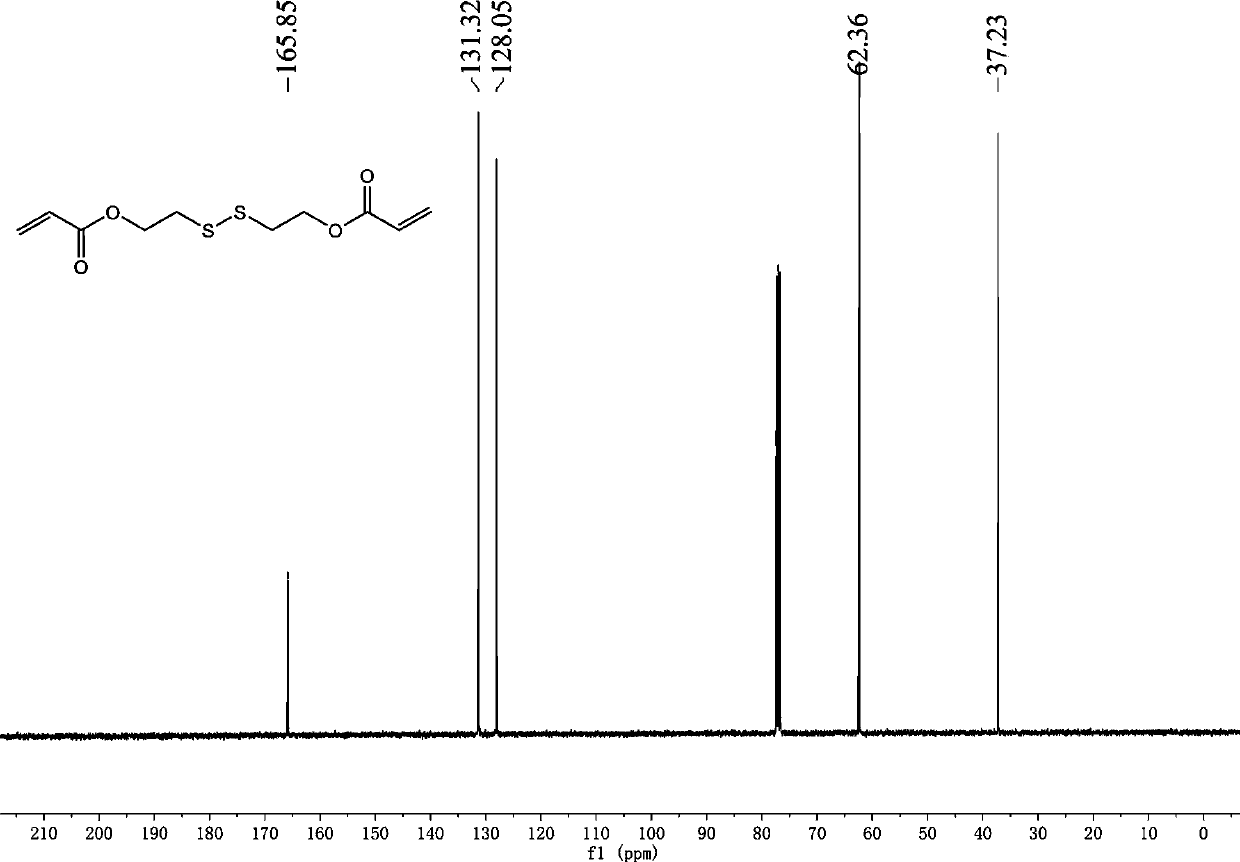

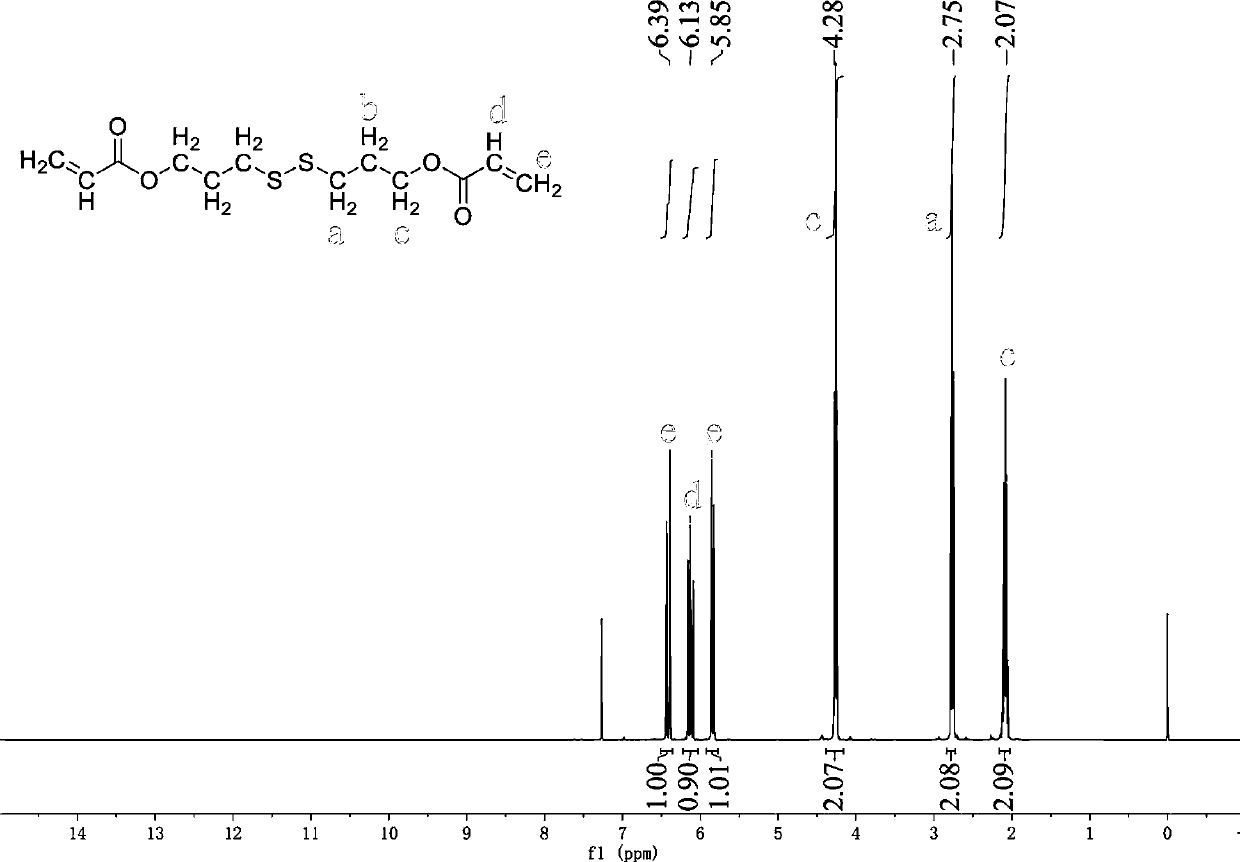

Preparation and application of polymerizable disulfide capable of reducing volume shrinkage

A technology of disulfide compounds and sulfhydryl compounds, applied in the field of polymer chemical materials, can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The polymerizable disulfide compound of the present invention, its preparation method and application are further described below in conjunction with the examples, but the present invention is not limited thereto.

[0027] raw material source

[0028] Hydrogen peroxide: Beijing Chemical Plant, chemical grade

[0029] Sodium iodide: Tianjin Fuchen Chemical Reagent Factory, chemical grade

[0030] Ethyl acetate: Beijing Chemical Plant, analytical grade

[0031] Petroleum ether: Beijing Chemical Plant, analytical grade

[0032] Acetonitrile: Beijing Chemical Plant, analytical grade

[0033] Chloroform: Beijing Chemical Plant, analytical grade

[0034] Tetrahydrofuran: Beijing Chemical Plant, analytical grade

[0035] Potassium carbonate: Beijing Chemical Plant, chemical grade

[0036] Sodium thiosulfate pentahydrate: Beijing Chemical Plant, chemical grade

[0037] Anhydrous magnesium sulfate: Beijing Chemical Plant, chemical grade

[0038] Mercaptoethanol: Tianjin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com