Magnetic separator for high frequency RFID electronic label and preparation method thereof

A technology of electronic label and magnetic isolation sheet, which is used in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of settlement, large amount of flake magnetic powder, short communication distance, etc., to prevent mutual contact and improve dispersion. performance, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

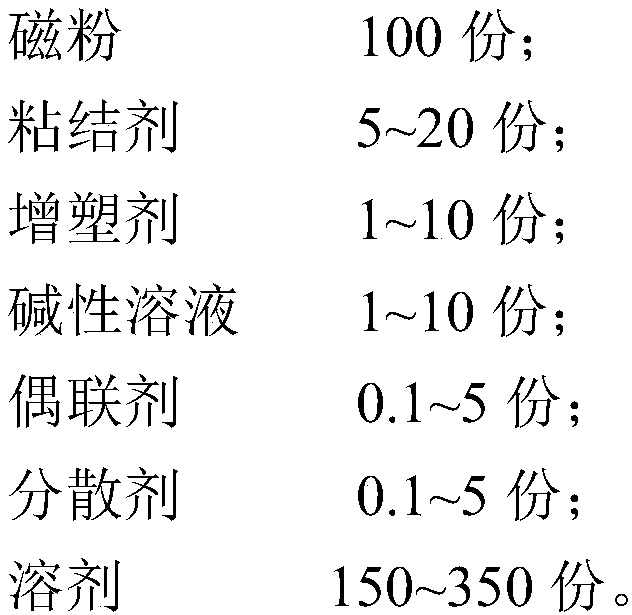

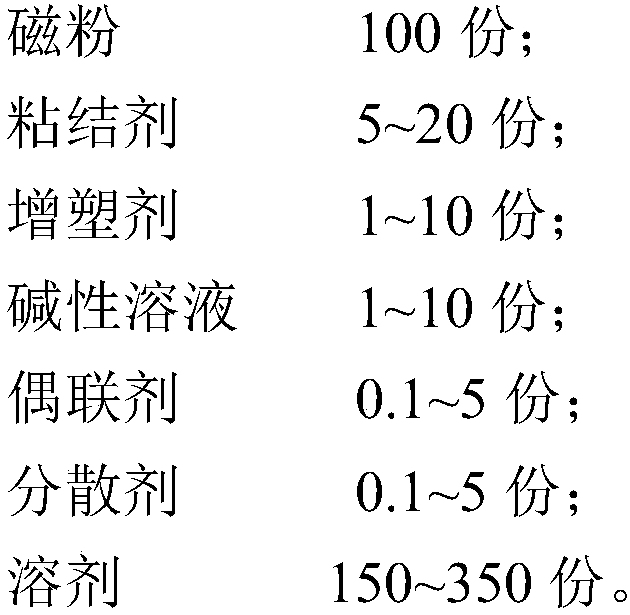

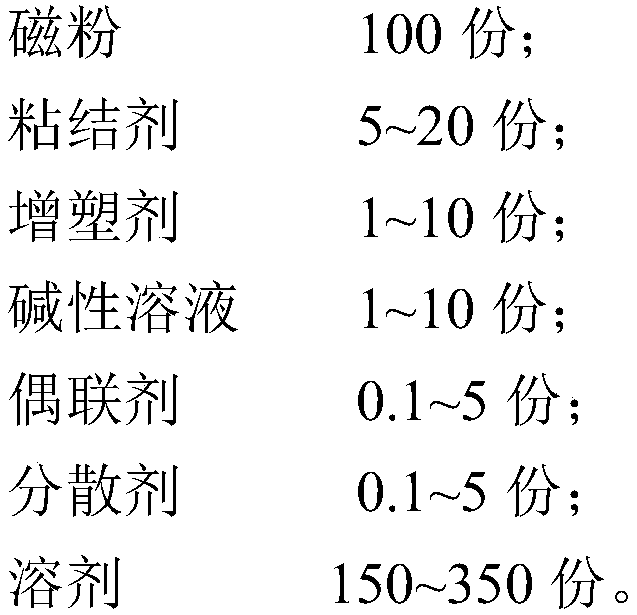

[0031] A magnetic isolation sheet for a high-frequency RFID electronic tag, comprising in parts by weight:

[0032]

[0033] The magnetic powder in this embodiment includes one or more of sendust, sendust, iron nickel and sendust. The magnetic powder in this embodiment is a kind of sendust.

[0034] The binder in this embodiment is a polymer, including one of polyvinyl butyral, polyvinyl alcohol acetal, ethyl cellulose, cellulose acetate butyrate, acrylic resin, epoxy resin and polyurethane. species or several.

[0035] Plasticizers in this embodiment are resins and other polymers with better flexibility; including o-phthalic polymers, triethyl phosphate, tributyl phosphate, polyester resins, modified epoxy resins, hydrogenated One or more of petroleum resin and silicone resin.

[0036] The alkaline solution in this embodiment is low-concentration sodium hydroxide or ammonia water.

[0037] The coupling agent in this embodiment is a silane coupling agent and a titanate ...

Embodiment 2

[0047] Add 100 parts by mass of a mixture of sendust and sendust magnetic powder (the mass ratio of sendust to sendust is 1:1) into a heated stirrer, and add 5 parts by mass of NaOH and 95 Parts by mass of ethanol, ball milled for 6 hours to fully wet and disperse the magnetic powder in the solvent, filter and dry, then mix 100 parts by mass of FeSiAl magnetic powder, 2 parts by mass of γ-aminopropyltriethoxysilane and 198 parts by mass Add ethanol into a heated mixer, ball mill for 6 hours to fully wet and evenly disperse the magnetic powder in the solvent, heat to 80°C, continue stirring until the magnetic powder is dry and take out the magnetic powder for later use. The magnetic powder of 100 mass parts is joined in the ball mill tank, and the zirconium ball of 200 mass parts, the ethanol of 75 mass parts, the amine salt of the xylene of 75 mass parts and the dispersant polycarboxylic acid of 5 mass parts, ball mill 6h make The magnetic powder is fully wetted and uniformly ...

Embodiment 3

[0051] Add 100 parts by mass of a mixture of sendust, sendust and iron-nickel (the mass ratio of sendust, sendust and iron-nickel is 1:2:1) into the heated In a mixer, add 10 parts by mass of NaOH and 90 parts by mass of ethanol, ball mill for 6 hours to fully wet and disperse the magnetic powder in the solvent, filter and dry, then mix 100 parts by mass of FeSiAl magnetic powder, 5 parts by mass of coupling Vinyltriethoxysilane and 195 parts by mass of ethanol were added to a heated mixer, ball milled for 6 hours to fully wet and evenly disperse the magnetic powder in the solvent, heated to 80°C, and continued to stir until the magnetic powder was dried and The magnetic powder is taken out for later use. The magnetic powder of 100 mass parts is joined in the ball mill tank, and the zirconium ball of 200 mass parts, the ethanol of 75 mass parts, the amine salt of the xylene of 75 mass parts and the dispersant polycarboxylic acid of 5 mass parts, ball mill 6h make The magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com