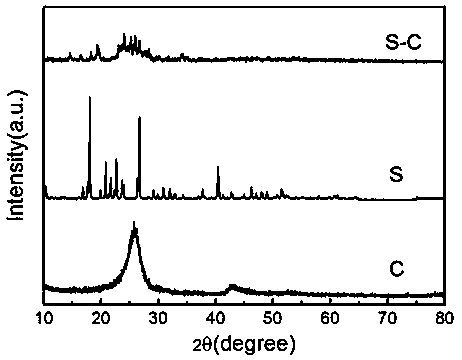

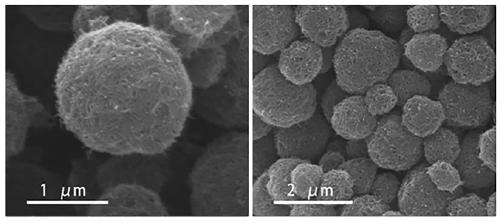

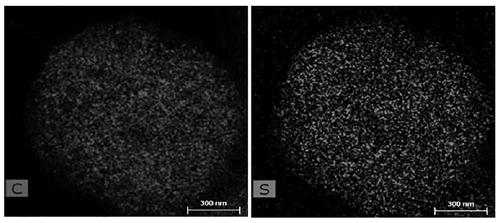

A kind of preparation method of wool spherical carbon/sulfur composite microsphere material and lithium-sulfur battery

A technology of composite microspheres and carbon microspheres, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reduced capacity of lithium-sulfur batteries, difficult practical use of fuel cells, and small specific capacity to improve electrochemical performance , reduce shuttle effect, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing a yarn spherical carbon / sulfur composite microsphere material, and the specific steps are as follows:

[0034] S1. Mix starch and polyvinyl alcohol into a binder at a ratio of 1:1, stir with an electromagnetic stirrer at room temperature for 3 hours to fully disperse the two, add kapok, the ratio of binder to kapok is 1:2 , performing shear stirring for 3 hours, then adding an appropriate amount of water, and ultrasonically dispersing for 5 hours to obtain a uniform mixed solution. The mixed solution has a suitable viscosity and is suitable for electrospinning treatment;

[0035] S2. The mixed solution obtained in step S1 is packed into a 50ml syringe, fixed on the support, the inner diameter of the nozzle is 1mm, and the nozzle is aimed at the circular receiving plate, and the distance between the nozzle and the circular receiving plate is 12cm. The receiving plate rotates at a speed of 10r / min. Under 40KV DC high voltage...

Embodiment 2

[0038] This embodiment provides a method for preparing a yarn spherical carbon / sulfur composite microsphere material, and the specific steps are as follows:

[0039] S1. Grind the catkins into powder and mix them with polyethylene glycol at a ratio of 2:1, perform shear stirring for 3 hours, then add an appropriate amount of water, and perform ultrasonic dispersion for 2 hours to obtain a uniform mixed solution. The mixed solution has a suitable viscosity and is suitable for Electrospinning treatment;

[0040] S2. The mixed solution obtained in step S1 is packed into a 50ml syringe, fixed on the support, the inner diameter of the nozzle is 2mm, and the nozzle is aimed at the circular receiving plate, and the distance between the nozzle and the circular receiving plate is 8cm. The receiving plate rotates at a speed of 10r / min. Under 40KV DC high voltage, the nozzle is connected to the positive pole, and the circular receiving plate is connected to the negative pole. The spinnin...

Embodiment 3

[0043] This embodiment provides a method for preparing a yarn spherical carbon / sulfur composite microsphere material, and the specific steps are as follows:

[0044] S1. Grind dandelion into powder and mix it with carboxymethyl cellulose in a ratio of 3:1, perform shear stirring for 4 hours, then add an appropriate amount of water, and perform ultrasonic dispersion for 2 hours to obtain a uniform mixed solution. The mixed solution has a suitable viscosity. Suitable for electrospinning;

[0045] S2. The mixed solution obtained in step S1 is packed into a 50ml syringe, fixed on the bracket, the inner diameter of the nozzle is 5mm, and the nozzle is aimed at the circular receiving plate, and the distance between the nozzle and the circular receiving plate is 20cm. The receiving plate rotates at a speed of 20r / min. Under 60KV DC high voltage, the nozzle is connected to the positive electrode, and the circular receiving plate is connected to the negative electrode. The spinning is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com