Preparation method of composite tubular part for moderating neutrons in nuclear reactor

A composite material and neutron-moderated technology, applied in the field of preparation of nuclear radiation protection materials, can solve problems such as poor performance of cylindrical parts and complex process flow, and achieve the effects of accurate and detailed data, simple process and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

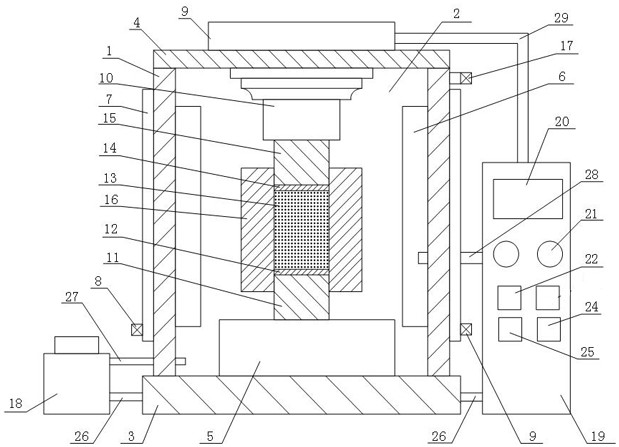

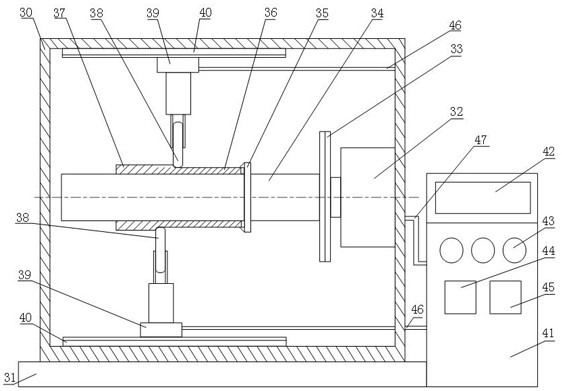

[0043] The preparation method of the composite tubular part for moderating neutrons in nuclear reactors is realized by the following steps:

[0044] 1) Determine raw materials and ratio

[0045] Select 6061Al aluminum alloy powder and graphite (C) powder, of which 6061Al aluminum alloy powder: graphite powder = 5:1;

[0046] 2) Preparation of cylindrical open-close mold

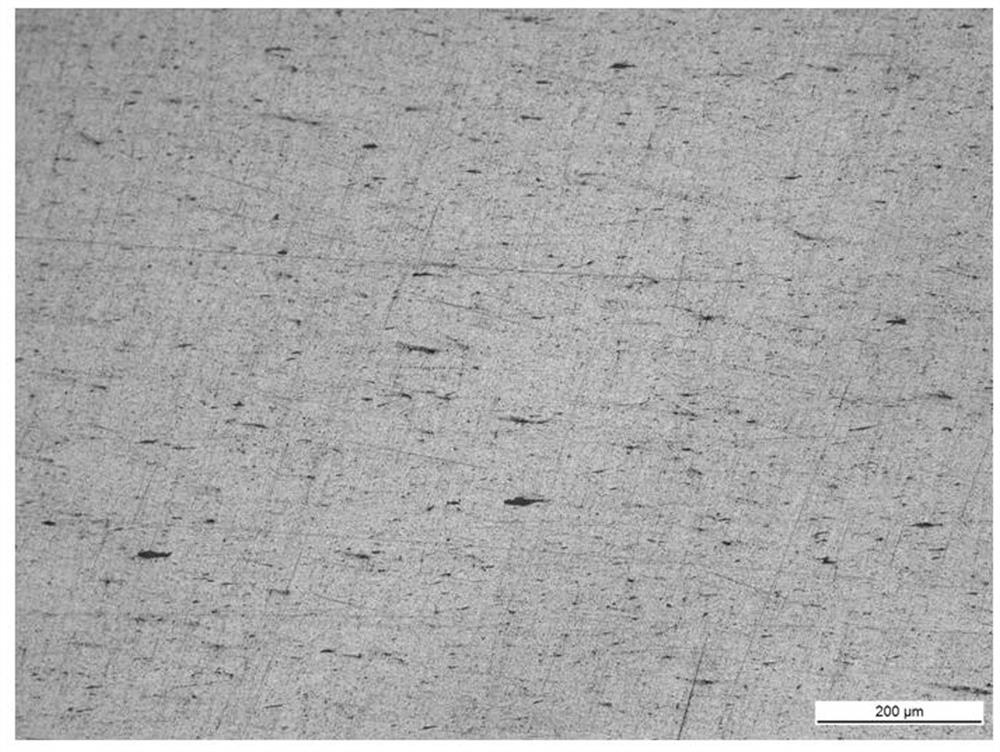

[0047] The cylindrical open-close mold is composed of a cylindrical main mold, a lower cushion block, and an upper cushion block; the cylindrical open-close mold is made of graphite material, and the surface roughness of the main mold cavity is Ra 0.08-0.16µm. Cavity size is Ø30mm×70mm;

[0048] 3) Ball milling and mixing powder

[0049]Put the 6061Al aluminum alloy powder and graphite powder into the ball mill tank at a ratio of 5:1, and then perform ball milling and mixing in the ball mill. The speed of the ball mill is 500r / min, and the time for ball milling and mixing is 8h. After ball milling, a mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com