Preparation method of honeycomb-shaped Mn-based low-temperature denitration catalyst

A denitrification catalyst and low-temperature denitrification technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as lack of pore expansion effect, dispersion of carrier pore distribution, and poor mechanical strength. Sulfur resistance and thermal stability, low firing shrinkage, and life-extending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

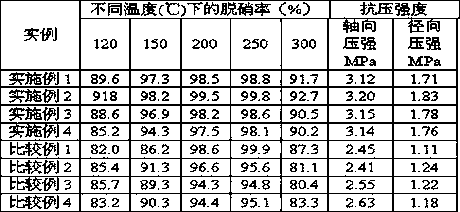

Examples

Embodiment 1

[0029] (1) Add the carbon black powder to the ethanol solution containing tetraethyl orthosilicate (where the solid-liquid mass ratio is 1:8, and the tetraethyl orthosilicate is SiO 2 The mass ratio of meter to carbon black powder is 2:1), under the condition of ultrasonic dispersion (the energy density of ultrasonic dispersion is 0.6kW / L, the temperature of ultrasonic dispersion is 40°C, and the time of ultrasonic dispersion is 1 hour), mix well, filter, The solid phase was dried at 50° C. for 2 hours, and then dried to obtain silicon source-modified carbon black powder;

[0030] (2) Add 54g of carbon black powder obtained in step (1) (based on the weight of carbon black powder), 600g of titanium sulfate, and 6g of nitric acid, then treat at 400°C in nitrogen for 3 hours, and roast at 500°C in air atmosphere for 5 hours. Obtain silicon-containing titania carrier;

[0031] (3) In the mixer, add 9 kg silicon-containing titanium oxide and 1kg A molecular sieve carrier, mix 0.4k...

Embodiment 2

[0034] (1) Add carbon black powder to ethanol solution containing tetraethyl orthosilicate (wherein the solid-liquid mass ratio is 1:12, and tetraethyl orthosilicate is SiO 2 The mass ratio of meter to carbon black powder is 3:1), under the condition of ultrasonic dispersion (the energy density of ultrasonic dispersion is 0.8kW / L, the temperature of ultrasonic dispersion is 60°C, and the time of ultrasonic dispersion is 1 hour), mix well, filter, The solid phase was dried at 60° C. for 2 hours, and then dried to obtain silicon source-modified carbon black powder;

[0035] (2) Add 120g of carbon black powder obtained in step (1) (based on the weight of carbon black powder), 900g of titanium sulfate, and 6g of nitric acid, then treat at 500°C in nitrogen for 3 hours, and roast at 500°C in air atmosphere for 5 hours. Obtain silicon-containing titania carrier;

[0036] (3) In the mixer, add 9.5 kg silicon-containing titanium oxide and 0.5 kg ZSM-5 molecular sieve carrier, 0.6 kg ...

Embodiment 3

[0039] (1) Add the carbon black powder to the ethanol solution containing tetraethyl orthosilicate (the solid-to-liquid mass ratio is 1:20, and the tetraethyl orthosilicate is SiO 2 The mass ratio of meter to carbon black powder is 4:1), under the condition of ultrasonic dispersion (the energy density of ultrasonic dispersion is 0.6kW / L, the temperature of ultrasonic dispersion is 40°C, and the time of ultrasonic dispersion is 1 hour), mix well, filter, The solid phase was dried at 50° C. for 2 hours, and then dried to obtain silicon source-modified carbon black powder;

[0040] (2) Add 150g of carbon black powder obtained in step (1) (by weight of carbon black powder), 800g of titanium sulfate, and 8g of nitric acid, then treat at 400°C in nitrogen for 3 hours, and roast at 500°C in air atmosphere for 5 hours. Obtain silicon-containing titania carrier;

[0041] (3) In the mixer, add 8.5 kg silicon-containing titanium oxide and 1.5 kg Y molecular sieve carrier, mix 0.2 kg 50%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com