Electrocatalytic oxidation method and reaction unit for difficult-to-degrade waste water

An electrocatalytic oxidation and reaction device technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of secondary pollution, large primary investment in equipment, and high operating energy consumption, and reduce Wastewater treatment cost, improved biodegradability, and effect of enhanced mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

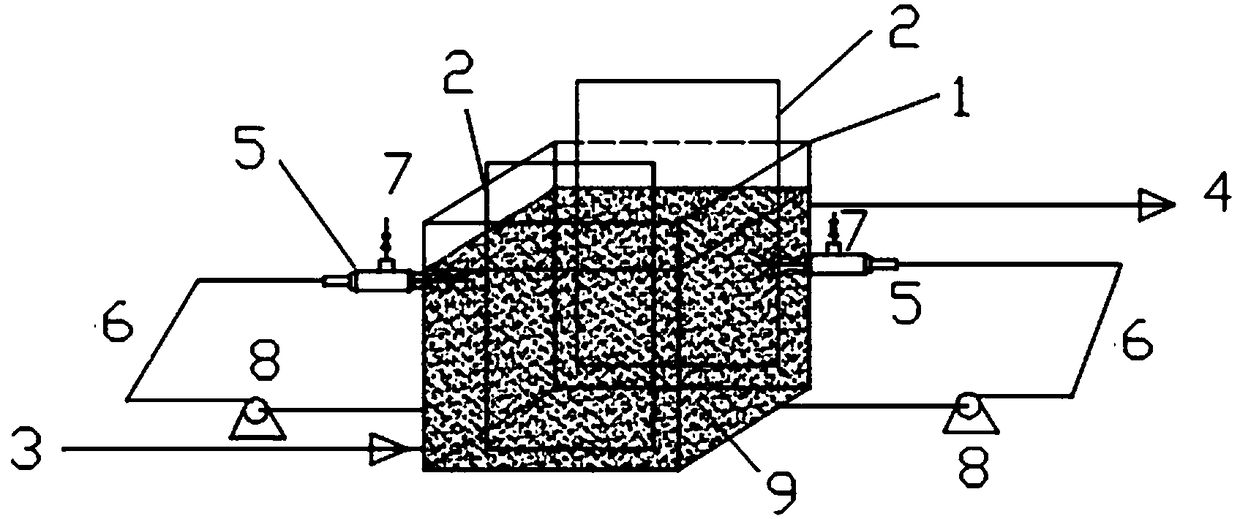

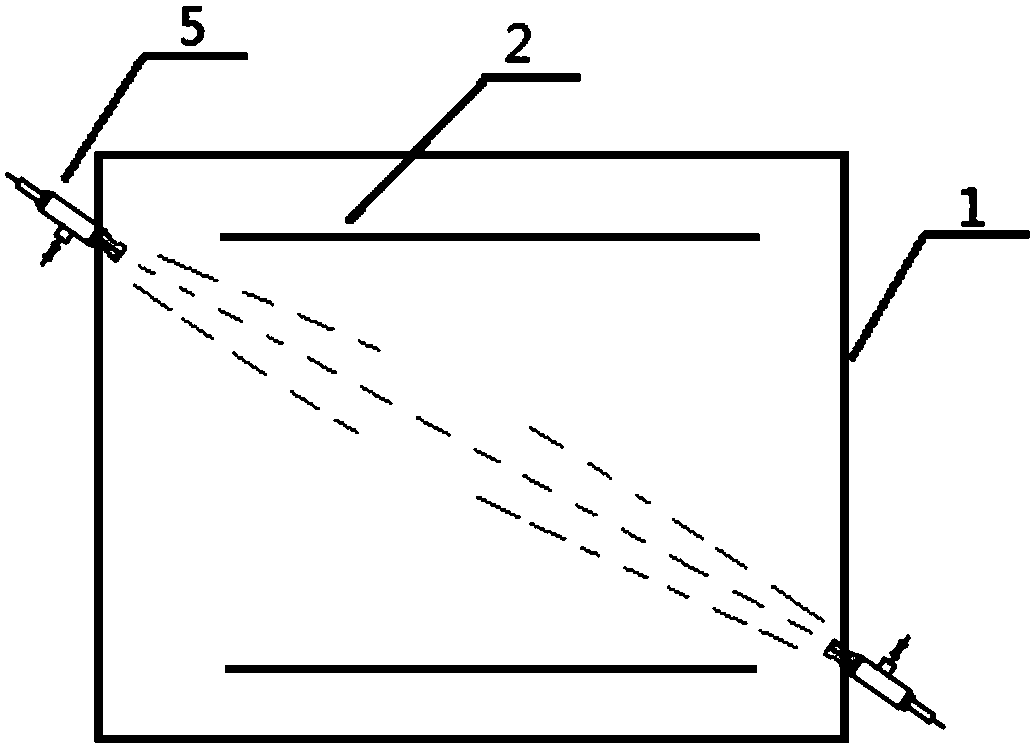

[0052] The electrocatalytic oxidation reaction device for refractory wastewater includes a reaction vessel 1 , an electrode plate 2 oppositely disposed in the reaction vessel 1 , and a total waste water inlet 3 and a total waste water outlet 4 . The reaction vessel 1 is filled with an electrocatalyst 9, and two injectors 5 are coaxially fixed on the side wall of the reaction vessel 1 facing each other. The air inlet 7 on the injector 5 communicates with the outside atmosphere, and the injection port at the front end is located inside the reaction vessel 1, so that the two jets generated by the injector 5 are ejected, and the electrocatalyst 9 generates a collision flow, and the waste water at the tail end of the injector 5 The inlet is located outside the reaction vessel 1 , and the waste water inlet communicates with the lower part of the reaction vessel 1 through the waste water circulation pipeline 6 . A circulation pump 8 is provided on the wastewater circulation pipeline ...

Embodiment 2

[0054] In the electrocatalytic oxidation reaction device used for refractory wastewater as in Example 1, the wastewater with biological toxicity and high organic matter content (BOD 5 / COD value is 0.1) into the reaction vessel 1 through the total waste water inlet 3, under the action of the circulation pump 8, the waste water sucks air through the air inlet 7, mixes with the waste water entering the injector 5, and the gas-liquid two-phase mixture flows out After the injector 5 passes through the electrocatalyst 9, it collides with each other coaxially. The voltage between the two electrode plates is 50V, and the current density is 0.01A / cm 2 , the electrocatalytic oxidation reaction of wastewater was carried out for 1h. After the reaction is completed, take a water sample to detect the BOD of the refractory wastewater 5 The / COD value is 0.6, indicating that the biodegradability has been greatly improved, and the subsequent biochemical method can be used for advanced treat...

Embodiment 3

[0058] In the electrocatalytic oxidation reaction device for refractory wastewater as in Example 1, the refractory wastewater (COD is 3940) with a salt content exceeding 2% enters the reaction vessel 1 through the total wastewater inlet 3, and the refractory wastewater in the circulation pump 8 Under the action of the air inlet 7, the wastewater sucks air and mixes with the wastewater entering the injector 5, and the gas-liquid two-phase mixture flows out of the injector 5 and passes through the electrocatalyst 9, colliding with each other coaxially. The voltage between the two electrode plates is 25V, and the current density is 0.05A / cm 2 , The electrocatalytic oxidation reaction of wastewater was carried out for 2h.

[0059] After the reaction, the water sample was taken for testing. The COD value of the wastewater after the reaction was 36. The test results showed that the pollutants had been removed to a great extent, and the removal rate was over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com