Hot-pressing filtration and dehydration process of filtrated mud in cane sugar factory

A filter dehydration, cane sugar technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, sludge treatment, etc., can solve the problem of high water content in filter mud and inconvenient transportation, storage and use , not accepted by farmers and other issues, to achieve the effect of increasing sugar yield, stable and reliable dehydration effect, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

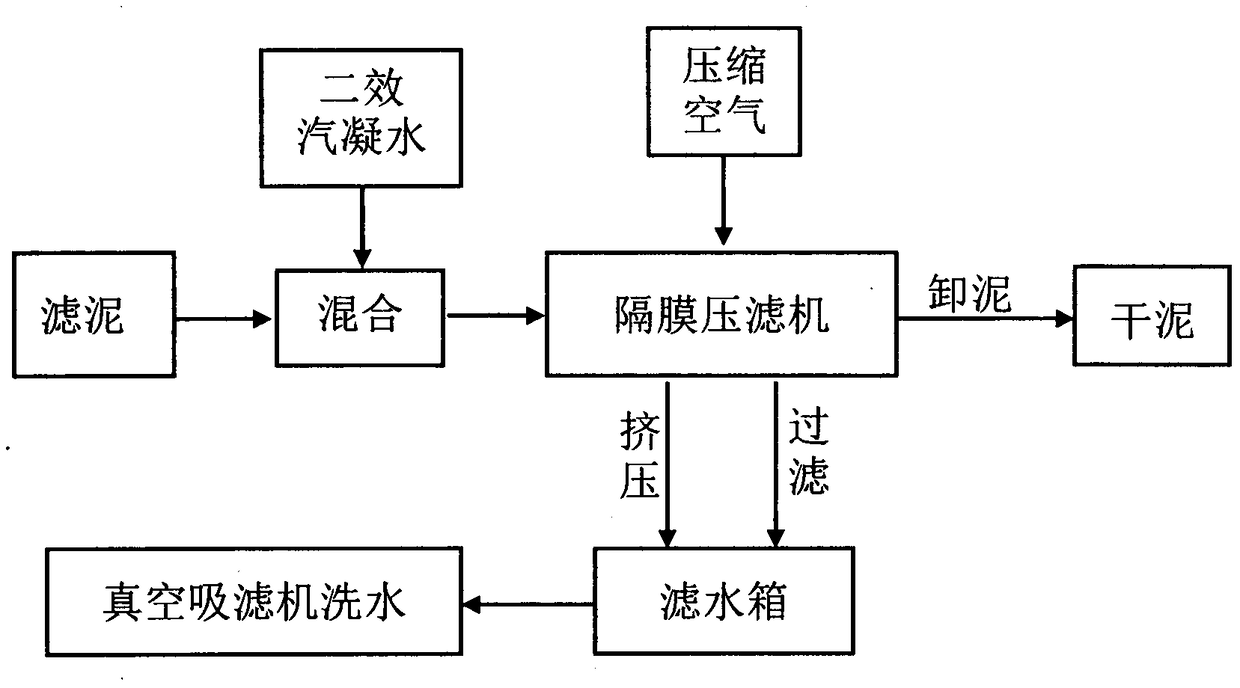

[0020] see figure 1 , a hot press dehydration process for filter sludge in sugarcane sugar factories. The specific technical plan is: use hot water above 70°C (condensed water produced by heating, evaporating or boiling sugar in the sugar production process can be used) and sugar factory The filter mud discharged from the vacuum suction filter is mixed and diluted into pumpable mud; the obtained mud is pumped into the diaphragm filter press for filtration, the filtrate is discharged into the filter water tank, and filtered until no filtrate flows out continuously, and the filter cake is obtained after the filtration is completed; Compressed air enters the membrane filter press to dehydrate the filter cake under pressure; the squeezed filtrate is discharged into the filter water tank, and is filtered until no filtrate flows out, and the mud is discharged to complete dehydration. The filtrate collected by the filter water tank is pumped to the vacuum suction filter of the sugar ...

Embodiment 2

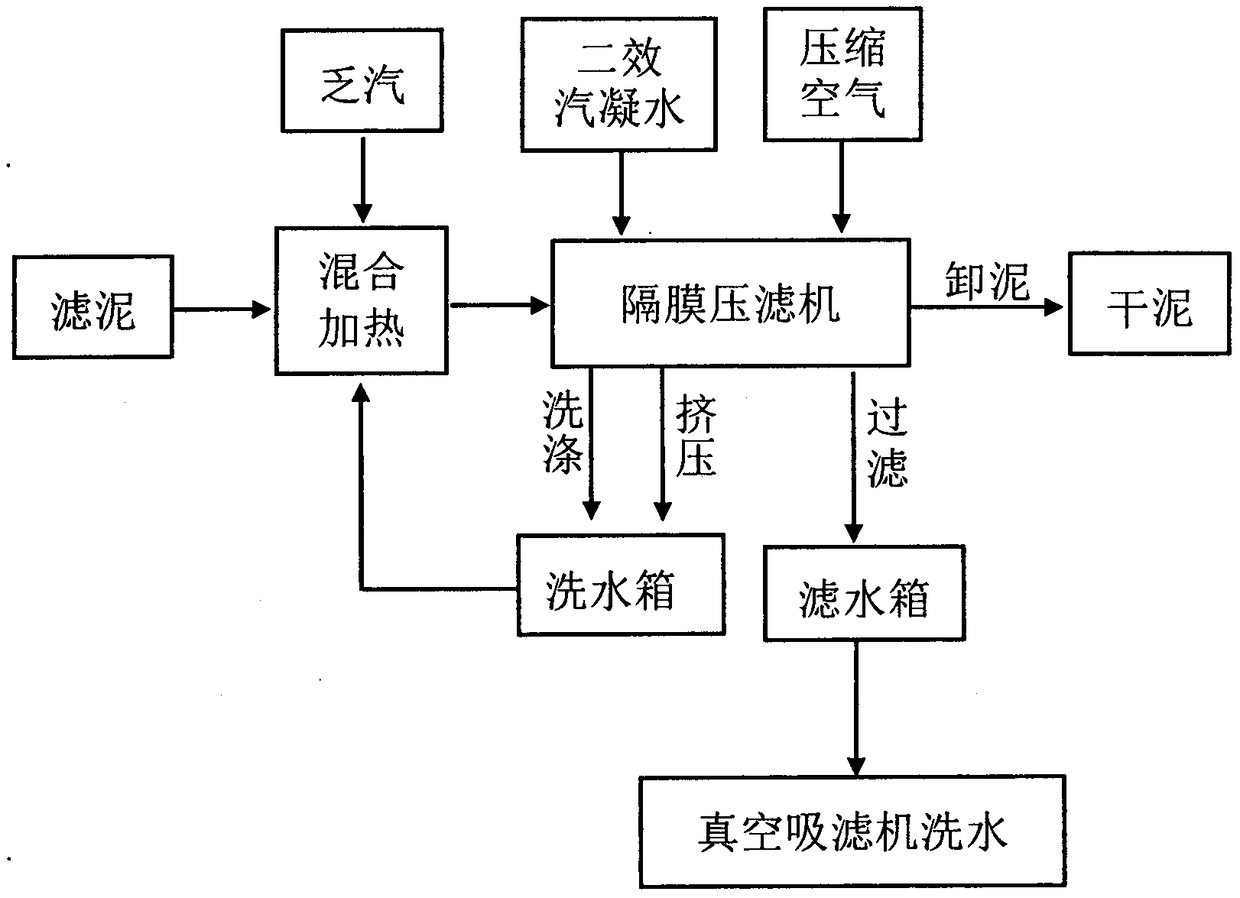

[0022] see figure 2 , a hot press dehydration process for sugarcane sugar factory filter mud, the specific technical scheme is: the filter mud discharged from the vacuum suction filter of the sugar factory uses the washing water in the washing water tank (when starting up, there is no washing water, other hot water in the sugar factory can be used ) to mix and dilute into a pumpable slurry, and use the exhaust steam discharged from the steam turbine in the sugar factory to feed the slurry and heat it to 70-100°C; the resulting slurry is pumped into a diaphragm filter press for filtration, and the filtrate is discharged into the filter water tank, and filtered until there is no filtrate After continuous outflow, the filter cake is obtained after the filtration is completed; then, the filter cake in the membrane filter press is washed with hot water above 80°C (the second-effect condensate discharged from the second-effect evaporation drum), and the washing water is discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com