Hollow porous microsphere catalytic material and preparation method thereof and application in NO degradation

A technology of porous microspheres and catalytic materials, applied in the field of denitrification catalyst nanomaterials, can solve the problems of small specific surface area, etc., and achieve the effect of large specific surface area, good medium and low temperature denitrification performance, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

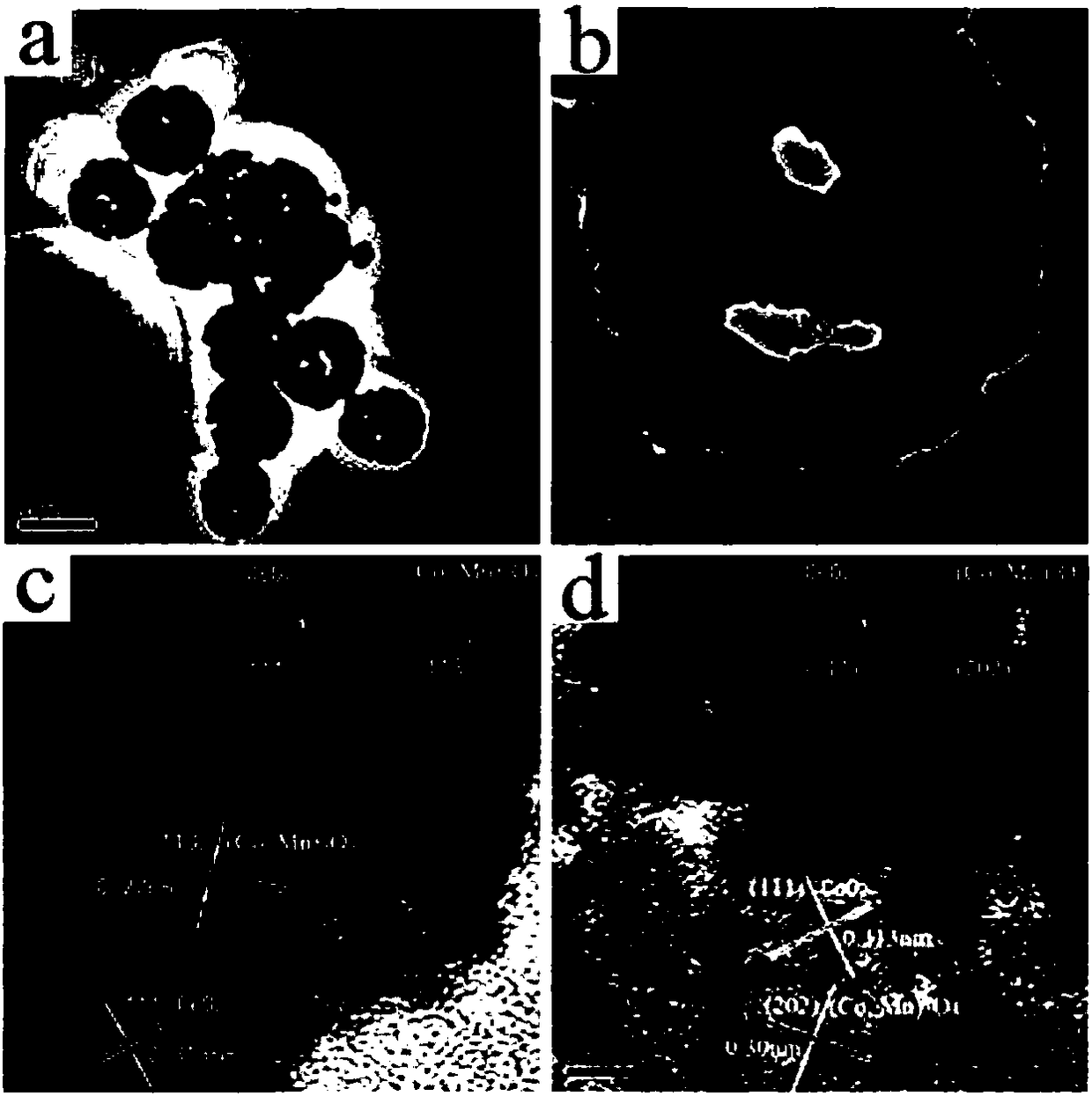

Image

Examples

Embodiment 1

[0029] A simple hydrothermal synthesis of cerium oxide composite cobalt-manganese (CeOx-(Co,Mn) 3 o 4 ) spinel denitration catalyst nanomaterials, prepared according to the following steps:

[0030] Step 1, cleaning solution preparation: mix concentrated hydrochloric acid and concentrated sulfuric acid in a volume ratio of 3:1 to prepare aqua regia, which is used as a clear solution for glass beakers and polytetrafluoroethylene reaction tanks;

[0031] Step 2, cleaning: Soak all the glass instruments used in the experiment with the prepared aqua regia for 10-20 minutes, then place them in an ultrasonic cleaner for 30 minutes, then wash them with distilled water for more than 10 times, and finally put them in a 70°C constant temperature drying oven drying spare;

[0032] Step 3, weigh 0.58g of cobalt nitrate Co(NO 3 ) 2 ·6H 2 O, stirred at 30°C for 20 minutes, dissolved in 15mL of ethylene glycol;

[0033] Step 4, weigh the manganese nitrate Mn(NO 3 ) 2 4H 2 O and 0.02...

Embodiment 2

[0040] A simple hydrothermal synthesis of cerium oxide composite cobalt-manganese (CeOx-(Co,Mn) 3 o 4 ) spinel denitration catalyst nanomaterials, prepared according to the following steps:

[0041] Step 1, cleaning solution preparation: mix concentrated hydrochloric acid and concentrated sulfuric acid in a volume ratio of 3:1 to prepare aqua regia, which is used as a clear solution for glass beakers and polytetrafluoroethylene reaction tanks;

[0042] Step 2, cleaning: Soak all the glass instruments used in the experiment with the prepared aqua regia for 10-20 minutes, then place them in an ultrasonic cleaner for 30 minutes, then wash them with distilled water for more than 10 times, and finally put them in a 70°C constant temperature drying oven drying spare;

[0043] Step 3, weigh 0.58g of cobalt nitrate Co(NO 3 ) 2 ·6H 2 O, stirred at 30°C for 20 minutes, dissolved in 15mL of ethylene glycol;

[0044] Step 4, weigh the manganese nitrate Mn(NO 3 ) 2 4H 2 O and 0.07...

Embodiment 3

[0051] A simple hydrothermal synthesis of cerium oxide composite cobalt-manganese (CeOx-(Co,Mn) 3 o 4 ) spinel denitration catalyst nanomaterials, prepared according to the following steps:

[0052] Step 1, cleaning solution preparation: mix concentrated hydrochloric acid and concentrated sulfuric acid in a volume ratio of 3:1 to prepare aqua regia, which is used as a clear solution for glass beakers and polytetrafluoroethylene reaction tanks;

[0053] Step 2, cleaning: Soak all the glass instruments used in the experiment with the prepared aqua regia for 10-20 minutes, then place them in an ultrasonic cleaner for 30 minutes, then wash them with distilled water for more than 10 times, and finally put them in a 70°C constant temperature drying oven drying spare;

[0054] Step 3, weigh 0.58g of cobalt nitrate Co(NO 3 ) 2 ·6H 2 O, stirred at 30°C for 20 minutes, dissolved in 15mL of ethylene glycol;

[0055] Step 4, weigh the manganese nitrate Mn(NO 3 ) 2 4H 2 O and 0.12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com