Silicon dioxide aerogel coating and preparation method thereof

A technology of silica and airgel, which is applied in the field of heat insulation and heat preservation materials, can solve the problems that professionals cannot realize, cannot realize, and poor thermal conductivity, so as to avoid difficult dispersion, good heat insulation effect, and structural collapse enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

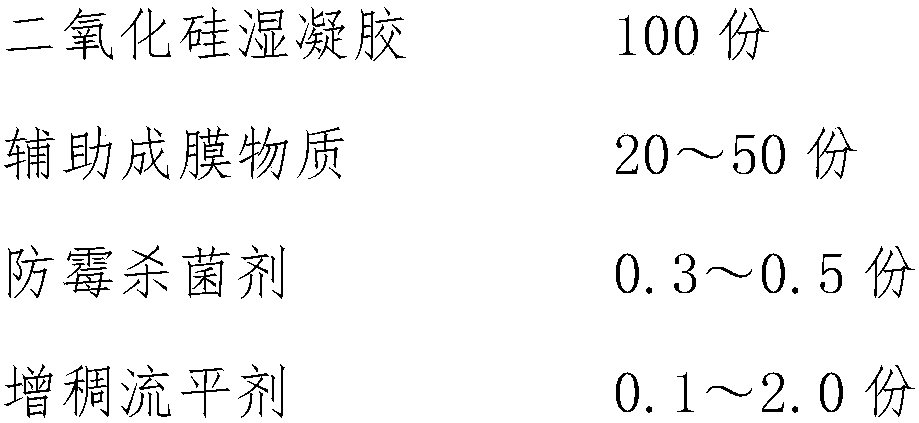

Method used

Image

Examples

Embodiment 1

[0021] Preparation of silica wet gel (take the patent document with publication number CN 103833041A as an example, but not limited to the above-mentioned patent document): add 60L of tetraethyl orthosilicate (TEOS) into a reaction kettle with 200L of ethanol After stirring at 200 rpm for 30 minutes, slowly add 2.5mol / L hydrochloric acid solution to adjust the pH value of the solution to about 3.5. After continuing to stir for 30 minutes, the reaction kettle was heated to a solution temperature of 45° C. and kept at a constant temperature for 24 hours. Add 3mol / L ammonia solution under stirring at 200 rpm, adjust the pH value of the system to about 7.5, keep stirring for 15 minutes, keep at a constant temperature of 45°C for 4 hours, add 30% content of γ-glycidyl ether propyl during stirring An aqueous solution of trimethoxysilane (gamma-glycidyl ether propyl trimethoxysilane stabilizer is added in an amount of 5-10% of the silica content), heated to 60° C. and stabilized for ...

Embodiment 2

[0027] The silica wet gel production process is the same as Case 1.

[0028] Add 1,000 kg of silica wet gel to the stirring tank, stir at 200 rpm, add 80 kg of 20% aluminum sol, 200 kg of silicone acrylic resin emulsion of RF2072, 4 kg of anti-mold and bactericide LXE, fiber 0.1 kg of plain thickener HEC, 5 kg of UH-420 polyurethane thickener, stir at 500 rpm for more than 30 minutes, add 5 kg of deionized water, and stir at 150 rpm for 10 minutes to complete the finished coating, which can be used in metal buckets or Filled in plastic barrels, the shelf life is more than 6 months.

[0029]The silicone acrylic resin emulsion RF2072 used was produced by Beijing Baowei Latex Company, and the polyurethane thickener UH-420 was produced by Japan Asahi Kawasaki Co., Ltd.

[0030] The resulting coating has a density of 0.95 g / ml, a viscosity of 1800 mPa·s, and a thermal conductivity of the coating of 0.021 W / m·K (GB / T22588-2008).

[0031] The paint obtained above is sprayed on the ...

Embodiment 3

[0033] The silica wet gel production process is the same as Case 1.

[0034] Add 1,000 kg of silica wet gel to the stirring tank, stir at 300 rpm, add 60 kg of 30% silica sol, 150 kg of RF2072 silicone acrylic resin, 4 kg of anti-mold and fungicide, cellulose thickener HEC 0.1 kg, 5 kg of UH-420 polyurethane thickener, stirring for more than 30 minutes, adding 3 kg of deionized water, stirring at 150 rpm for 10 minutes to complete the finished coating, which can be filled in metal buckets or plastic buckets, with a shelf life of 6 months above.

[0035] The silicone acrylic resin emulsion used was produced by Beijing Baowei Latex Company, and the polyurethane thickener was produced by Japan Asahi Kawasaki Co., Ltd. The resulting coating has a density of 0.93 g / ml, a viscosity of 1500 mPa·s, and a thermal conductivity of the coating of 0.019 W / m·K (GB / T22588-2008).

[0036] The paint obtained above is sprayed on the wood with an air sprayer, the thickness of the coating is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com