Method for performing high-density fermentation on bacillus aceticus

A technology of high-density fermentation and acetic acid bacteria, which is applied in the field of high-density fermentation of acetic acid bacteria, can solve the problems of long cultivation period and achieve the effect of shortening the production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

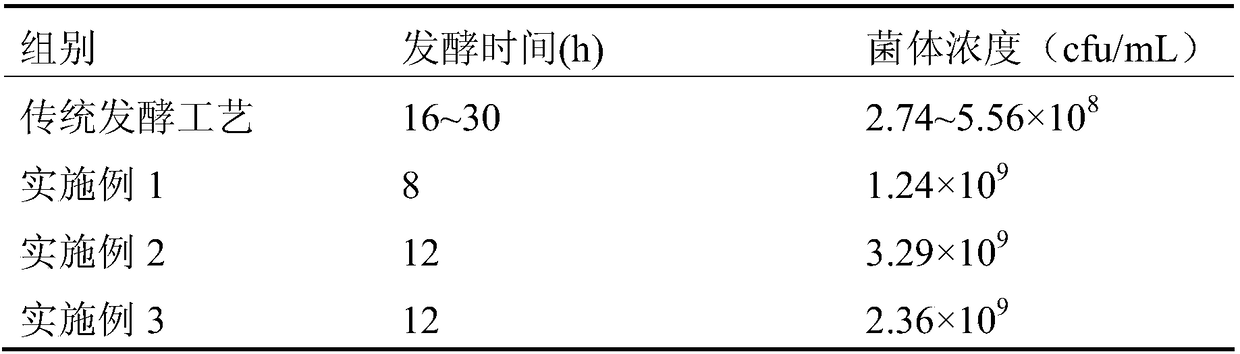

Examples

Embodiment 1

[0021] A high-density fermentation method for acetic acid bacteria, comprising the steps of:

[0022] (1) Activation of strains: pick well-growing Acetobacter seeds from the preservation medium and inoculate them on the agar medium, and cultivate them at 30°C for 24 hours to obtain activated strains; the composition of the agar medium is: yeast extract 1 %, glucose 1%, agar 2%, ethanol 2%, pH 5.5-6.0, percentages are mass percentages, and the balance is water;

[0023] (2) Shake flask culture: Inoculate the activated bacteria in step (1) into the shake flask, shake and cultivate for 18 hours, and obtain the seed liquid; shake flask medium formula: yeast extract 1%, glucose 1%, KH 2 P0 4 0.25%, ethanol 2%, pH 5.5-6.0, the percentages are mass percentages, and the balance is water; the liquid volume in a 250mL shaker flask is 50mL; culture conditions: shaker flask speed 150rpm, temperature 30°C;

[0024] (3) Seed tank expansion: the liquid cultured in the shake flask is used ...

Embodiment 2

[0027] A high-density fermentation method for acetic acid bacteria, comprising the steps of:

[0028] (1) strain activation and shake flask culture are the same as in Example 1

[0029] (2) Seed tank expansion: the liquid cultivated by the shake flask is inserted into a 10L fermenter with an inoculum size of 10% as the seed liquid and cultivated; the liquid volume of the 10L fermenter is 60%; the composition of the culture medium: yeast extract 4%, Glucose 5%, KH 2 P0 4 0.75%, ethanol 2%, pH 5.5-6.0; culture conditions: stirring speed 300rpm, ventilation volume 1vvm, temperature 30°C, adding 5M sodium hydroxide, controlling the pH of the fermentation broth to 5.5-6.0, culture time 10h;

[0030] (3) Fermentation tank fermentation: Transplant by pressure difference, the seed liquid in the seed tank is inserted in the fermentation tank by 10% inoculum amount and fermented; 100L fermentation tank liquid volume 70%; Culture medium composition: yeast paste 4 %, Glucose 5%, KH 2...

Embodiment 3

[0032] A high-density fermentation method for acetic acid bacteria, comprising the steps of:

[0033] (1) strain activation and shake flask cultivation are the same as in Example 1, and the seed tank expansion is the same as in Example 2;

[0034] (2) Fermentation tank fermentation: Transplant by pressure difference, the seed liquid in the seed tank is inserted in the fermentation tank by 10% inoculum amount and fermented; 100L fermentation tank liquid volume 70%; Culture medium composition: yeast extract 4 %, Glucose 5%, KH 2 P0 4 0.75%, ethanol 2%, pH 5.5-6.0; culture conditions: stirring speed 300rpm, ventilation 1vvm, temperature 30°C, adding 5M sodium hydroxide, controlling the pH of the fermentation broth to 5.5-6.0, and adding light at the same time Density OD 600 =2 cell slurry and 5g / L bitter gourd polypeptide (the addition amount of these two substances is 300mL respectively), and the culture time is 12h. Described cell slurry refers to fermented liquid (number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com