All-optical switch based on sulfur phase-change material and preparation method thereof

A phase change material, all-optical switching technology, applied in the field of optical communication, can solve the problems of large loss, difficult large-scale integration, slow switching rate, etc., and achieve the effect of large switching ratio, low loss and high rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

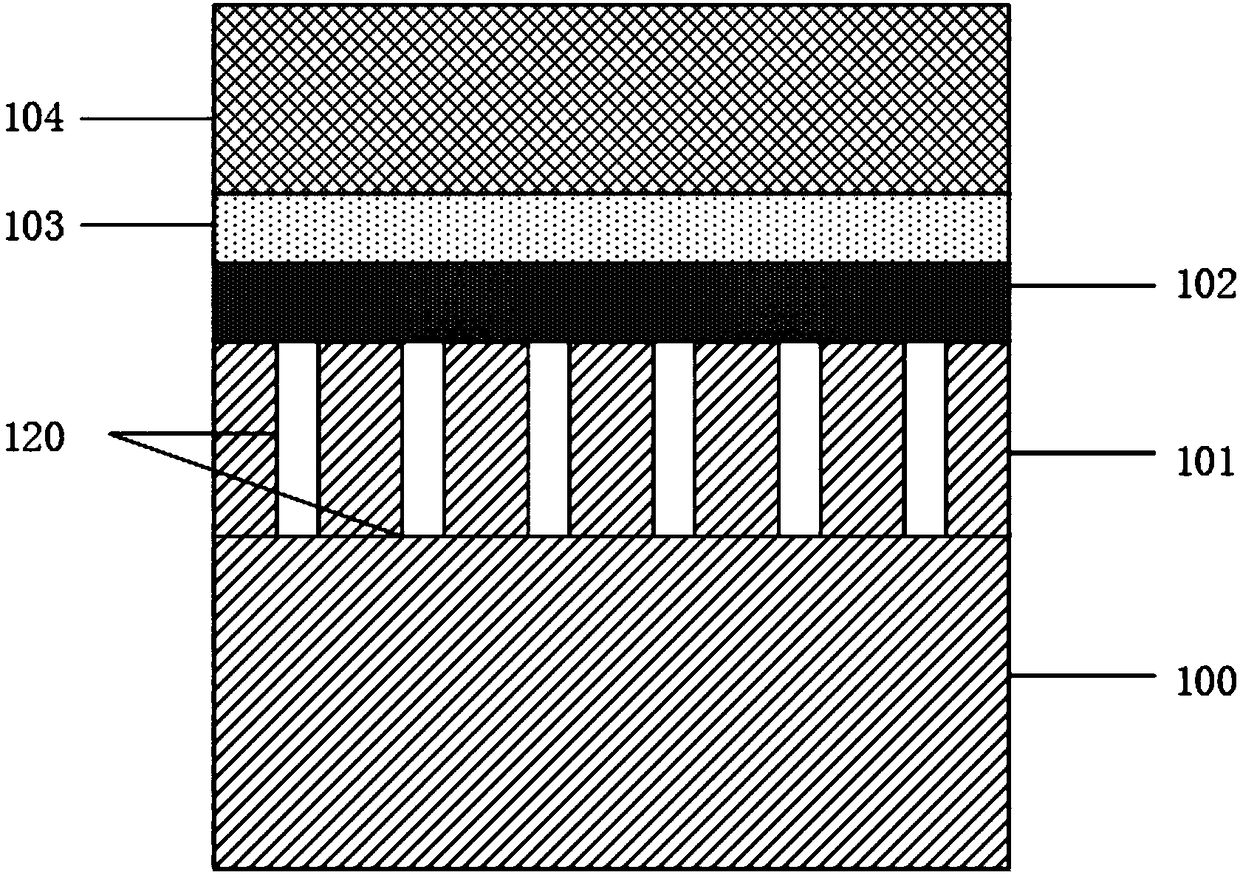

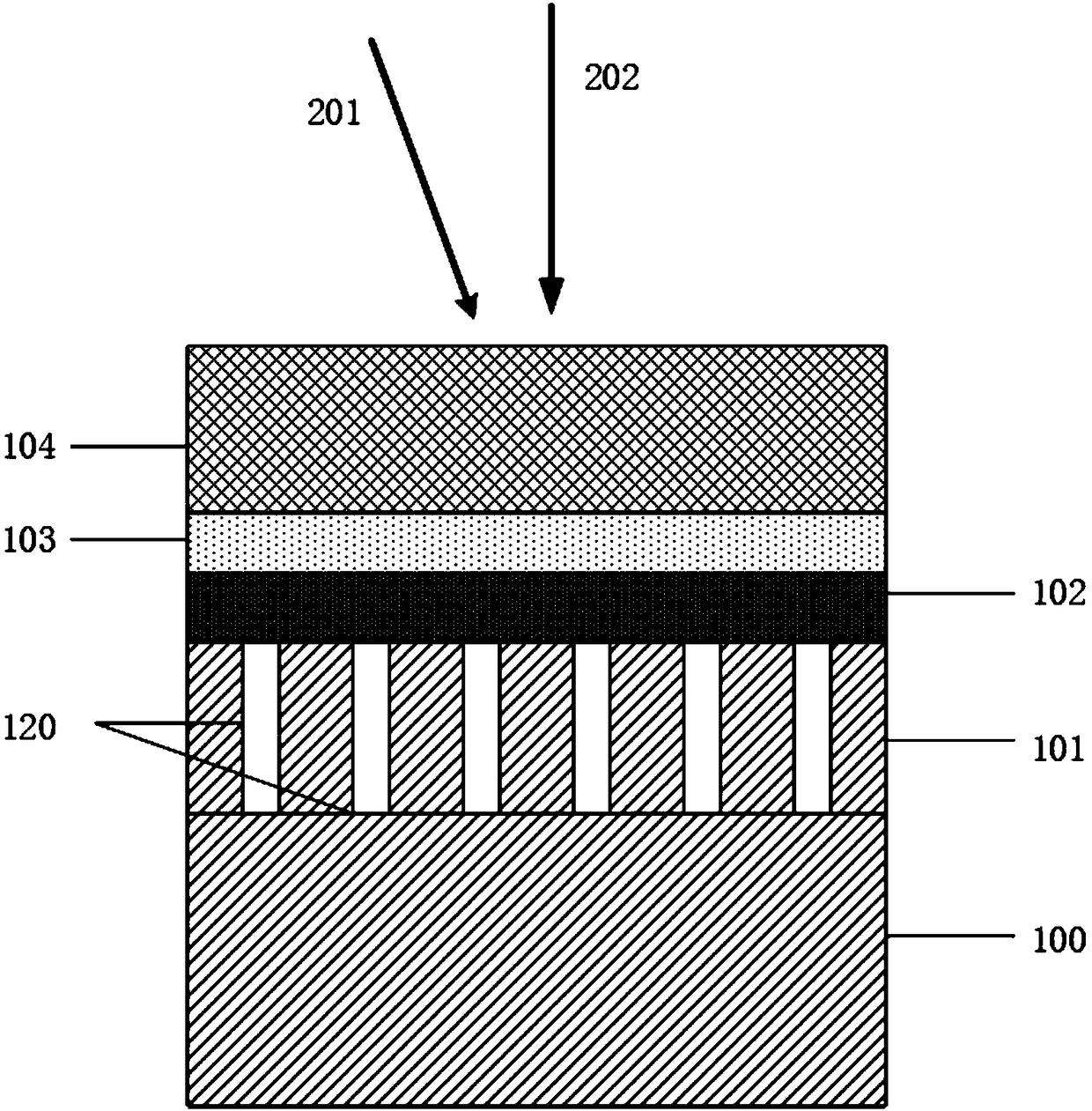

[0047] A method for preparing an all-optical switch based on a chalcogenide phase-change material, comprising:

[0048] (1) On the substrate, a single crystal silicon material is deposited, and nanoholes are etched on the single crystal silicon material to form silicon photonic crystals. The radius of the nanoholes is 50nm, the distance between the holes is 700nm, and the hole depth is 150nm;

[0049] (2) Deposit a layer of SiO with a thickness of 15nm above the silicon photonic crystal 2 film;

[0050] (3) Deposit a layer of 5nm GeTe on the top of the isolation layer film;

[0051] (4) On top of the chalcogenide phase change material film, deposit a layer of SiN with oxidation resistance of 20nm x film, to obtain an all-optical switch. Etching is electron beam lithography and deposition is chemical vapor deposition.

Embodiment 2

[0053] A method for preparing an all-optical switch based on a chalcogenide phase-change material, comprising:

[0054] (1) On the substrate, a single crystal silicon material is deposited, and nanoholes are etched on the single crystal silicon material to form silicon photonic crystals. The radius of the nanoholes is 90nm, the distance between the holes is 850nm, and the hole depth is 250nm;

[0055] (2) Deposit a layer of SiO with a thickness of 40nm above the silicon photonic crystal 2 film;

[0056] (3) Deposit a layer of 25nm SbTe above the isolation layer film;

[0057] (4) On top of the chalcogenide phase change material film, deposit a layer of 200nm SiO with oxidation resistance 2 film, to obtain an all-optical switch. Etching is electron beam lithography and deposition is radio frequency magnetron sputtering.

Embodiment 3

[0059] A method for preparing an all-optical switch based on a chalcogenide phase-change material, comprising:

[0060] (1) On the substrate, a single crystal silicon material is deposited, and nanoholes are etched on the single crystal silicon material to form silicon photonic crystals. The radius of the nanoholes is 70nm, the distance between the holes is 800nm, and the hole depth is 200nm;

[0061] (2) Deposit a layer of SiN with a thickness of 30nm above the silicon photonic crystal x film;

[0062] (3) Deposit a layer of 15nm Bi on top of the isolation layer film 2 Te 3 ;

[0063] (4) Deposit a layer of 100nm SiO with oxidation resistance on top of the chalcogenide phase change material film 2 / ZnS film to obtain an all-optical switch. The etching is ion-coupled plasma etching, and the deposition is DC magnetron sputtering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com