Germanium single crystal wafer and manufacturing method thereof, crystal rod manufacturing method and use of single crystal wafer

A germanium single wafer, germanium single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of reducing the photoelectric conversion efficiency and open circuit voltage of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0123] In the method for preparing germanium single crystal rods of the present invention, the atomic concentration of silicon in the effective length of germanium single crystal rods is preferably 2×10 14 atoms / cc to 8×10 18 atoms / cc, more preferably 3×10 14 atoms / cc up to 7×10 18 atoms / cc; and the atomic concentration of gallium is preferably 2×10 16 atoms / cc to 9×10 19 atoms / cc, more preferably 2×10 16 atoms / cc to 8×10 19 atoms / cc.

[0124] Alternatively, in the method for preparing a germanium single crystal rod of the present invention, the atomic concentration of silicon within the effective length of the germanium single crystal rod is 1-25ppm based on the amount of germanium, and the atomic concentration of gallium is based on the amount of germanium 1-100ppm.

[0125] Alternatively, in the method for preparing a germanium single crystal rod of the present invention, the atomic concentration of silicon within the effective length of the germanium single crystal ...

Embodiment 1

[0224] Use 10kg bulk high-purity germanium raw material, 0.5g dopant gallium (50 ppm based on high-purity germanium raw material) and diboron trioxide liquid sealing agent.

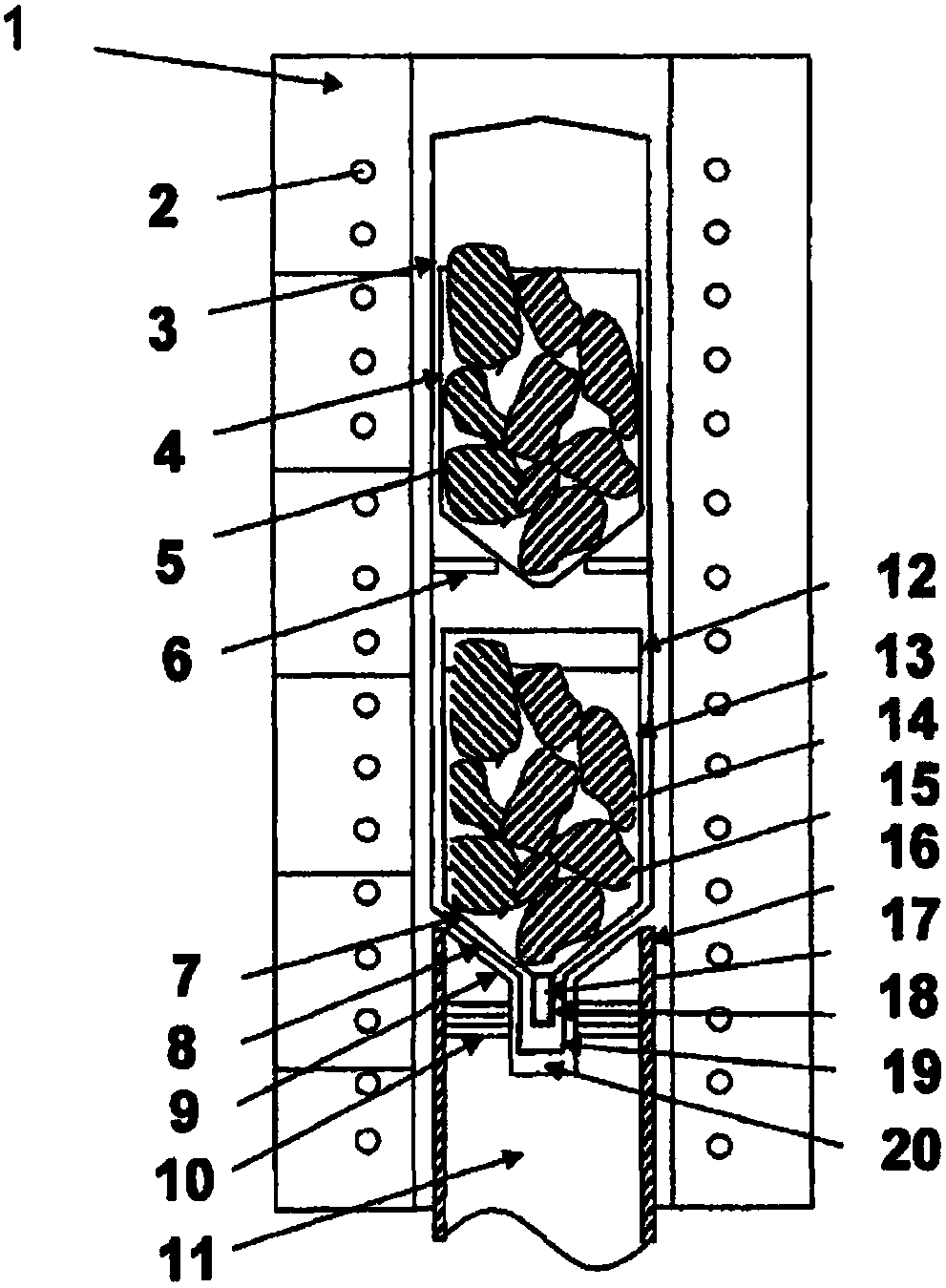

[0225] 1) 65% of the above-mentioned amounts of massive high-purity germanium, gallium, and diboron trioxide are respectively loaded into the first growth crucible, and the seed crystal groove of the first growth crucible is pre-installed with seeds;

[0226] 2) Put the remaining 35% of high-purity germanium and gallium into the second feeding crucible above the first growth crucible;

[0227] 3) Put the first growth crucible and the second feeding crucible into the quartz tube, and put them under vacuum at 10 -5 Sealed quartz tube under the condition of Torr;

[0228] 4) Put the quartz tube sealed with the first growth crucible and the second feeding crucible obtained in step 3) into a crystal growth furnace with a movable quartz tube support, which is used to support the quartz tube;

[0229] 5) Start...

Embodiment 2

[0233] Use 10kg bulk high-purity germanium raw material, 0.5g dopant gallium (50ppm based on high-purity germanium raw material), 0.01g dopant silicon (1ppm based on high-purity germanium raw material) and diboron trioxide liquid sealant .

[0234] 1) 65% of the above-mentioned amounts of massive high-purity germanium, gallium, silicon, and boron trioxide are respectively loaded into the first growth crucible, and the seed crystal groove of the first growth crucible is pre-installed with seeds;

[0235] 2) Put the remaining 35% of high-purity germanium, gallium, silicon and boron trioxide into the second feed crucible above the first growth crucible;

[0236] 3) Put the first growth crucible and the second feeding crucible into the quartz tube, and put them under vacuum at 10 -5 Sealed quartz tube under the condition of Torr;

[0237]4) Put the quartz tube sealed with the first growth crucible and the second feeding crucible obtained in step 3) into a crystal growth furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com