An n-type doped electron transport layer and tio 2 Layer perovskite cell fabrication method

A technology of electron transport layer and perovskite battery, which is applied in semiconductor/solid-state device manufacturing, circuit, photovoltaic power generation, etc. It can solve the problems of poor stability of perovskite, reduce internal defects, promote improvement, and improve short-circuit current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An n-type doped electron transport layer and TiO 2 A method for preparing a layered perovskite battery, comprising the following steps:

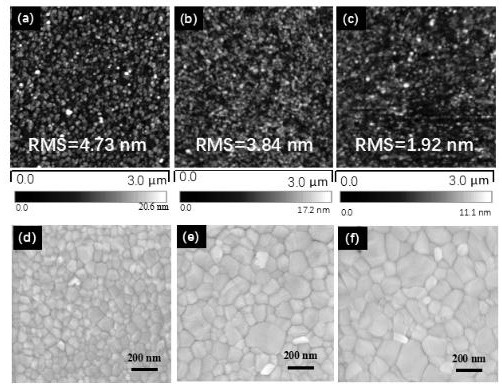

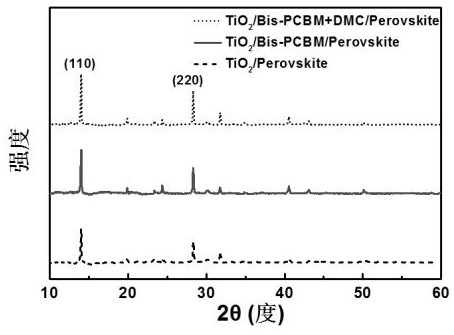

[0028] (1) FTO transparent conductive glass substrate cleaning and TiO 2 Film preparation: The FTO transparent conductive glass substrate was repeatedly ultrasonically cleaned with deionized water, acetone and ethanol for 3 times, and then dried at 100 °C to completely remove the solvent and moisture. and ozone treatment for 25 min, and then deposit the electron transport layer TiO on the treated FTO transparent conductive glass substrate 2 , put it in a 100°C oven for later use;

[0029] (2) Preparation of Bis-PCBM and DMC composite film: Dissolve 5 mg Bis-PCBM in 2 mL of chlorobenzene, stir for 4 h to obtain a Bis-PCBM solution, and then dissolve the dopant DMC in ethanol to prepare a precursor solution with a concentration of 0.2mg / mL, the precursor solution was doped in Bis-PCBM solution, and the volume ratio of the two was 0.0...

Embodiment 2

[0036] An n-type doped electron transport layer and TiO 2 A method for preparing a layered perovskite battery, comprising the following steps:

[0037] (1) FTO transparent conductive glass substrate cleaning and TiO 2 Film preparation: The FTO transparent conductive glass substrate was repeatedly ultrasonically cleaned with deionized water, acetone and ethanol for 3 times, and then dried at 100 °C to completely remove the solvent and moisture. and ozone treatment for 25 min, and then deposit the electron transport layer TiO on the treated FTO transparent conductive glass substrate 2 , put it in a 100°C oven for later use;

[0038] (2) Preparation of Bis-PCBM and DMC composite film: Dissolve 5 mg Bis-PCBM in 2 mL of chlorobenzene, stir for 4 h to obtain a Bis-PCBM solution, and then dissolve the dopant DMC in ethanol to prepare a precursor solution with a concentration of 0.2mg / mL, the precursor solution was doped in Bis-PCBM solution, and the volume ratio of the two was 0.1...

Embodiment 3

[0045] An n-type doped electron transport layer and TiO 2 A method for preparing a layered perovskite battery, comprising the following steps:

[0046] (1) FTO transparent conductive glass substrate cleaning and TiO 2 Film preparation: The FTO transparent conductive glass substrate was repeatedly ultrasonically cleaned with deionized water, acetone and ethanol for 3 times, and then dried at 100 °C to completely remove the solvent and moisture. and ozone treatment for 25 min, and then deposit the electron transport layer TiO on the treated FTO transparent conductive glass substrate 2 , put it in a 100°C oven for later use;

[0047] (2) Preparation of Bis-PCBM and DMC composite film: Dissolve 5 mg Bis-PCBM in 2 mL of chlorobenzene, stir for 4 h to obtain a Bis-PCBM solution, and then dissolve the dopant DMC in ethanol to prepare a precursor solution with a concentration of 0.2mg / mL, the precursor solution was doped in Bis-PCBM solution, and the volume ratio of the two was 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com