Process method for producing sodium chromate with carbon ferrochrome with high temperature soda fusion liquid phase oxidation method

A technology of carbon ferrochrome and process method, applied in the chemical industry, chromate/dichromate, sustainable manufacturing/processing, etc., can solve problems such as shortening the production process, and achieve convenient capacity expansion and fast response Fast, easy-to-equip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

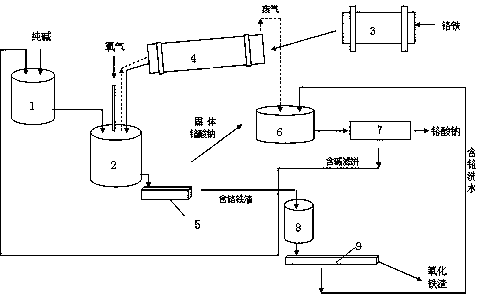

[0025] Example 1: Grinding high-carbon ferrochrome (100-200 mesh) containing 7%-10% carbon and heating and drying, pouring the heated molten liquid-phase soda ash (900-1000°C) into the preheated over 800°C In the liquid-phase oxidation furnace, add ferrochromium into the oxidation furnace evenly and pass in pure oxygen to carry out the oxidation reaction. The reaction temperature is kept at 1000-1300°C to control the oxidation reaction. The reaction produces anhydrous sodium chromate and iron oxide. After cooling and separating, the anhydrous sodium chromate is made into a sodium chromate solution by water immersion, and the reagent A is added to fully stir and mature, and then filtered to remove iron oxide slag and impurities. Carbon dioxide is passed into the filtrate for pre-carbonization, and the pH value of the solution is controlled so that impurities such as silicon and aluminum are successively precipitated. After the solution is filtered, a pure sodium chromate soluti...

Embodiment 2

[0026] Example 2: Grinding high-carbon ferrochrome (100-200 mesh) containing 7%-10% carbon and preheating it to about 500°C with exhaust gas, pouring the heated molten liquid phase soda ash (900-1000°C) into the pre-heated In a special liquid-phase oxidation furnace with a heat greater than 800°C, add ferrochrome evenly into the oxidation furnace and introduce rich oxygen to carry out the oxidation reaction. The reaction temperature is kept at 1000-1300°C to control the oxidation reaction. After the reaction, anhydrous sodium chromate and iron oxide are produced. After cooling and separating, anhydrous sodium chromate is made into sodium chromate solution by water immersion, and reagent A is added, fully stirred and matured, and then filtered to remove iron oxide slag and impurities. Carbon dioxide is passed into the filtrate for pre-carbonization, and the pH value of the solution is controlled so that impurities such as silicon and aluminum are successively precipitated. Afte...

Embodiment 3

[0027] Example 3: Grinding medium-high carbon ferrochrome (100-200 mesh) containing 3%-6% carbon and preheating it to about 500°C with waste gas, pouring the heated molten liquid-phase soda ash (900-1000°C) into the pre-heated In a special liquid-phase oxidation furnace with a heat greater than 800°C, add ferrochrome evenly into the oxidation furnace and introduce rich oxygen to carry out the oxidation reaction. The reaction temperature is kept at 1000-1300°C to control the oxidation reaction. After the reaction, anhydrous sodium chromate and iron oxide are produced. After cooling and separating, anhydrous sodium chromate is made into sodium chromate solution by water immersion, and reagent A is added, fully stirred and matured, and then filtered to remove iron oxide slag and impurities. Carbon dioxide is passed into the filtrate for pre-carbonization, and the pH value of the solution is controlled so that impurities such as silicon and aluminum are successively precipitated. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com